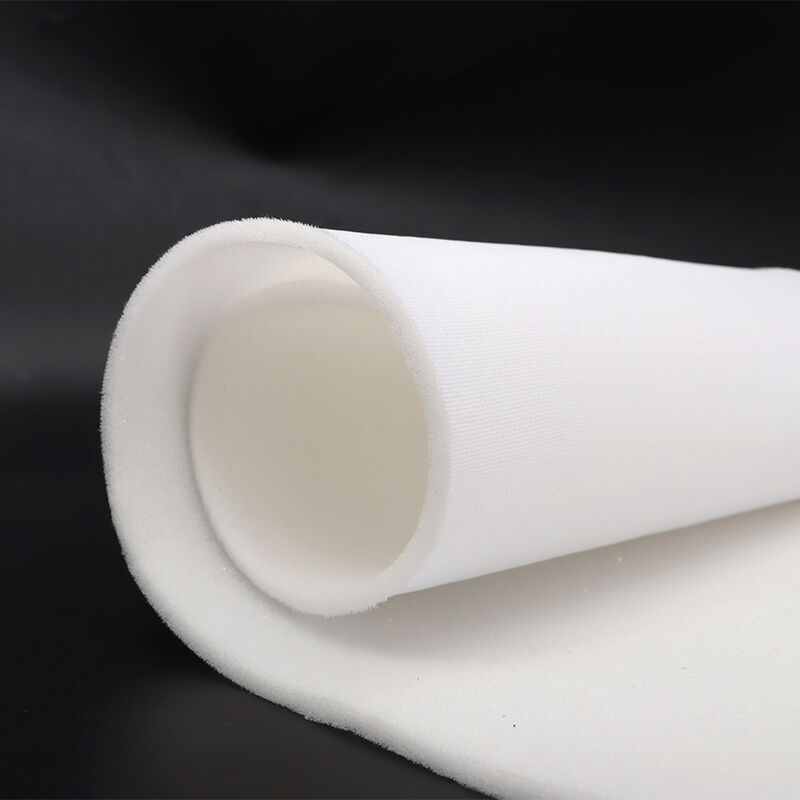

foam laminated

Foam laminated represents a cutting-edge manufacturing process that combines foam materials with various substrates through advanced lamination techniques. This innovative material construction consists of multiple layers bonded together, typically including a foam core and outer protective layers. The process creates a versatile composite material that offers enhanced durability, insulation properties, and structural integrity. The foam core provides excellent cushioning and shock absorption, while the laminated outer layers contribute to moisture resistance and surface protection. This technology finds extensive applications across industries, from automotive and construction to packaging and sports equipment. The manufacturing process involves precise temperature control and pressure application to ensure optimal bonding between layers, resulting in a uniform and reliable product. The versatility of foam laminated materials allows for customization in terms of density, thickness, and surface finish, making them suitable for diverse applications. Modern foam lamination techniques incorporate advanced adhesive systems and quality control measures to ensure consistent product performance and longevity. The material's ability to combine lightweight properties with structural strength makes it particularly valuable in applications where weight reduction is crucial without compromising on protection and functionality.