How Laminated Fabrics Improve Durability in Outdoor Gear

Outdoor gear is subject to challenging environmental conditions including wind, rain, UV exposure, and physical abrasion. Choosing the right materials for jackets, tents, backpacks, and protective gear is crucial for performance and longevity. Laminated fabrics have emerged as a primary solution, providing enhanced durability, weather resistance, and functionality. This article explores how laminated fabrics improve durability in outdoor gear, their manufacturing processes, types, advantages, and future innovations.

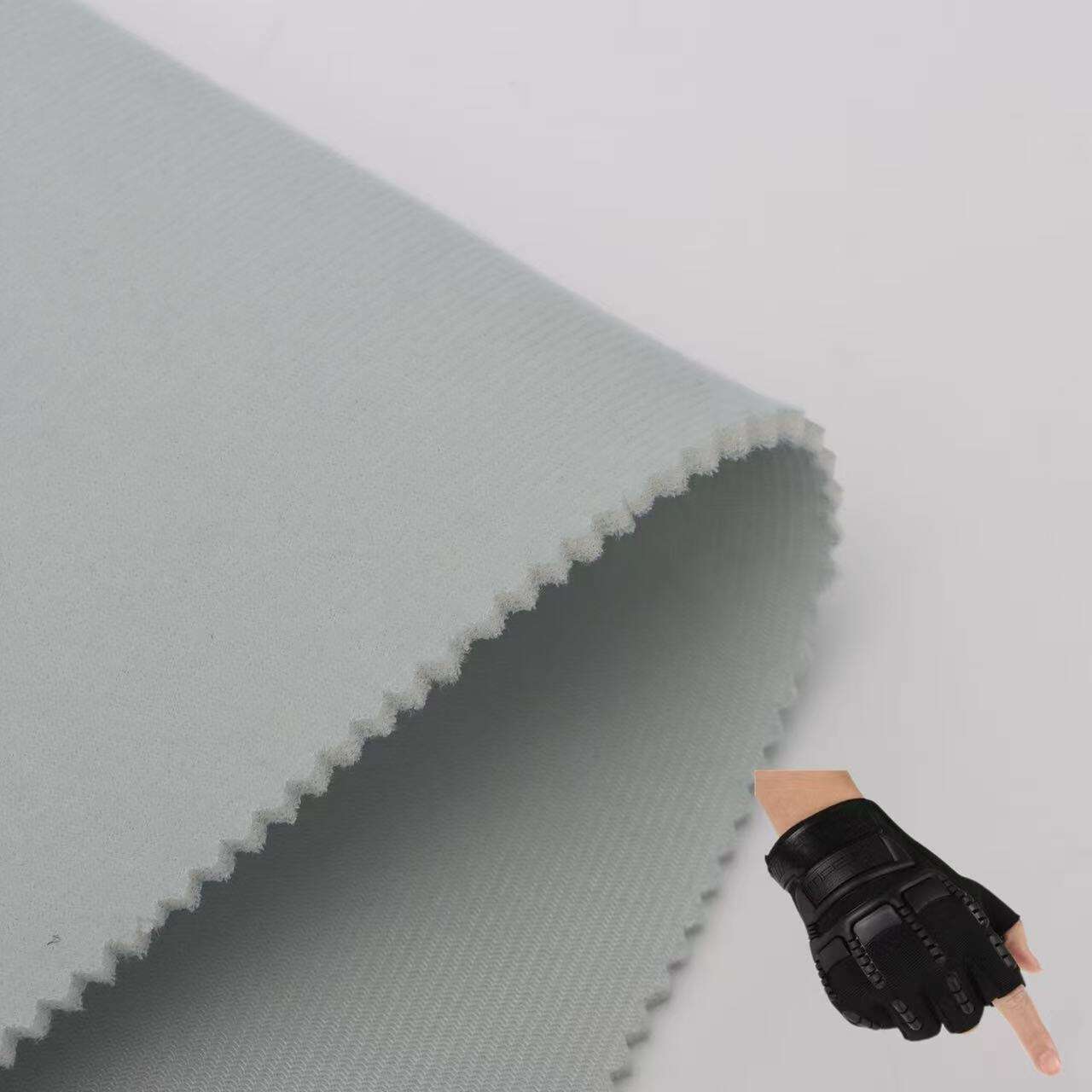

Understanding Laminated Fabrics

Laminated fabrics are composite materials created by bonding two or more layers of textiles with films, membranes, or foams. The lamination process combines the structural strength and flexibility of fabric with the functional benefits of the laminated layers, such as waterproofing, windproofing, thermal insulation, or abrasion resistance.

The fabric layer provides comfort, stretch, and aesthetic appeal, while the laminated layer enhances durability and environmental protection. These materials act as a cohesive unit, ensuring that outdoor gear maintains its shape, performance, and resilience under challenging conditions.

Importance of Durability in Outdoor Gear

Durability is a fundamental requirement for outdoor gear. Hikers, climbers, and adventurers depend on garments and equipment that can withstand rain, snow, wind, dirt, and physical stress. A failure in material performance can lead to discomfort, reduced safety, and a shorter lifespan for the gear. Laminated fabrics enhance durability by combining multiple protective layers into a single material, providing long-lasting performance while remaining lightweight and flexible.

Durable materials also improve value for consumers and reduce environmental impact by extending the life of outdoor gear and reducing waste. By integrating laminated fabrics, manufacturers can ensure that their products withstand repeated use and harsh environmental conditions.

Types of Laminated Fabrics Used in Outdoor Gear

Waterproof Laminated Fabrics

Waterproof laminated fabrics are widely used in rain jackets, tents, and protective outer layers. They typically combine a textile layer with a waterproof film such as polyurethane or polyvinyl chloride. These fabrics prevent water penetration while maintaining flexibility and comfort.

Breathable Laminated Fabrics

Breathable laminated fabrics allow moisture vapor to escape while preventing liquid water from passing through. This is often achieved using microporous membranes laminated to fabric layers. Breathable laminates are ideal for outdoor apparel, as they prevent overheating and improve comfort during physical activity.

Foam Laminated Fabrics

Foam-laminated fabrics provide cushioning, insulation, and padding for outdoor gear such as backpacks, sleeping pads, and protective clothing. Foam layers add durability by absorbing impact and reducing wear on the fabric surface.

Technical Laminated Fabrics

Technical laminated fabrics are engineered for extreme conditions. They combine multiple layers, including textiles, films, and protective coatings, to resist abrasion, UV exposure, chemical contact, and mechanical stress. These fabrics are commonly used in climbing gear, workwear, and safety equipment.

Laminated Fashion Fabrics

Laminated fashion fabrics are designed to combine functionality and aesthetics. They are used in stylish outerwear and high-performance outdoor clothing where waterproofing, wind resistance, and durability are essential without sacrificing design.

How Laminated Fabrics Are Manufactured

The lamination process ensures a strong bond between layers, resulting in a durable material capable of withstanding harsh conditions.

Heat Lamination

Heat lamination uses heat and pressure to bond films or membranes to fabric layers. This technique activates adhesive properties or melts the laminating material to form a strong, permanent bond. Heat lamination is commonly used for waterproof and breathable outdoor fabrics.

Adhesive Lamination

Adhesive lamination involves applying a liquid or solid adhesive to one or both surfaces before pressing them together. The adhesive is then cured to form a durable bond. This method allows lamination of foam or delicate fabrics that may not tolerate high heat.

Extrusion Lamination

Extrusion lamination melts a thermoplastic material and applies it directly onto the fabric surface. As it cools, it forms a durable bond. This technique is used for industrial and technical outdoor fabrics requiring high resistance to wear and chemicals.

Hot-Melt Lamination

Hot-melt lamination uses a thermoplastic adhesive activated by heat and pressure. It allows precise control over adhesive thickness and distribution, producing flexible and durable laminated fabrics suitable for outdoor gear.

Ultrasonic and Pressure Lamination

Ultrasonic lamination uses high-frequency vibrations to bond layers without adhesives or excessive heat. Pressure lamination enhances bonding for multi-layered materials. These techniques are increasingly used in outdoor gear for precise construction and minimal material alteration.

Advantages of Laminated Fabrics in Outdoor Gear

Enhanced Durability

Laminated fabrics combine the strength of textiles with protective layers that resist abrasion, moisture, and UV exposure. This makes outdoor gear long-lasting and able to withstand repeated use.

Weather Resistance

Waterproof and windproof laminates protect users from rain, snow, and strong winds. Breathable laminated fabrics allow moisture to escape, preventing discomfort caused by sweat accumulation.

Flexibility and Comfort

Despite multiple layers, laminated fabrics remain flexible and comfortable. This ensures freedom of movement while maintaining protection, which is critical for outdoor activities like hiking, climbing, or skiing.

Lightweight Construction

Laminated fabrics provide protection and durability without adding significant weight, keeping outdoor gear comfortable and practical for long-term use.

Improved Shape Retention

The laminated layers help garments maintain their shape over time, reducing sagging, wrinkling, and deformation even with frequent use.

Seamless Integration

Advanced lamination techniques enable seamless construction, reducing the need for stitching. This improves waterproofing, durability, and aesthetic appeal in outdoor gear.

Applications of Laminated Fabrics in Outdoor Gear

Jackets and Outerwear

Laminated fabrics in jackets and outerwear provide windproofing, waterproofing, insulation, and durability. Breathable laminates prevent overheating, ensuring comfort during physical activity.

Tents and Shelters

Waterproof laminated fabrics are essential for tents and outdoor shelters, providing protection from rain while resisting tearing and abrasion.

Backpacks and Bags

Foam-laminated and technical laminated fabrics enhance the durability of backpacks, protecting contents from impact and environmental conditions while providing structural support.

Protective Clothing

Outdoor workwear and safety clothing rely on laminated fabrics for chemical resistance, UV protection, and abrasion resistance. Laminated fabrics allow workers to perform tasks safely and comfortably.

Sports and Adventure Gear

Laminated fabrics are widely used in gloves, pads, climbing harnesses, and sleeping bags, offering a balance of durability, flexibility, and comfort.

Design Considerations for Laminated Fabrics

Designing outdoor gear with laminated fabrics requires careful consideration of material properties, intended use, and environmental conditions. Manufacturers must select laminates with appropriate thickness, breathability, and abrasion resistance. Multi-layer laminates can be engineered to provide varying protection levels across different areas of the gear. Proper selection ensures comfort, durability, and functionality for end-users.

Future Trends in Laminated Fabrics for Outdoor Gear

Sustainability is a growing trend in laminated fabric production. Manufacturers are developing eco-friendly laminates using recycled films, biodegradable adhesives, and low-emission processes. Digital lamination and advanced extrusion techniques allow thinner, lighter, and more versatile fabrics. Smart textiles may integrate sensors within laminated layers, enabling real-time monitoring of temperature, moisture, or pressure.

Advances in antimicrobial coatings, UV resistance, and flame-retardant laminates are expanding the functionality of outdoor gear, ensuring safety and performance for extreme activities.

Conclusion

Laminated fabrics significantly improve durability in outdoor gear by combining multiple protective layers with textiles that provide comfort and flexibility. Through heat, adhesive, extrusion, and hot-melt lamination techniques, manufacturers create materials that resist water, wind, UV exposure, abrasion, and chemical stress. From jackets and tents to backpacks and protective clothing, laminated fabrics enhance longevity, comfort, and performance. By understanding types, manufacturing processes, and applications, outdoor gear designers and consumers can make informed choices that balance durability, functionality, and comfort. Laminated fabrics continue to evolve, offering innovative solutions for modern outdoor challenges.

FAQ

What are laminated fabrics?

Laminated fabrics are composite materials made by bonding two or more layers of fabric with films, foams, or membranes to enhance durability, waterproofing, and other functional properties.

How are laminated fabrics manufactured?

They can be produced using heat lamination, adhesive lamination, extrusion lamination, hot-melt lamination, or ultrasonic and pressure lamination techniques depending on the materials and intended use.

Why are laminated fabrics important for outdoor gear?

Laminated fabrics provide durability, weather resistance, comfort, and shape retention, ensuring that outdoor gear performs reliably in harsh conditions.

Can laminated fabrics remain breathable?

Yes, breathable membranes and microporous laminates allow moisture vapor to escape while preventing liquid water from entering, maintaining comfort during physical activity.

Where are laminated fabrics used in outdoor gear?

Applications include jackets, tents, backpacks, protective clothing, gloves, pads, sleeping bags, and other outdoor sports and adventure equipment.

Table of Contents

- How Laminated Fabrics Improve Durability in Outdoor Gear

- Understanding Laminated Fabrics

- Importance of Durability in Outdoor Gear

- Types of Laminated Fabrics Used in Outdoor Gear

- How Laminated Fabrics Are Manufactured

- Advantages of Laminated Fabrics in Outdoor Gear

- Applications of Laminated Fabrics in Outdoor Gear

- Design Considerations for Laminated Fabrics

- Future Trends in Laminated Fabrics for Outdoor Gear

- Conclusion

- FAQ