custom laminated foam fabric

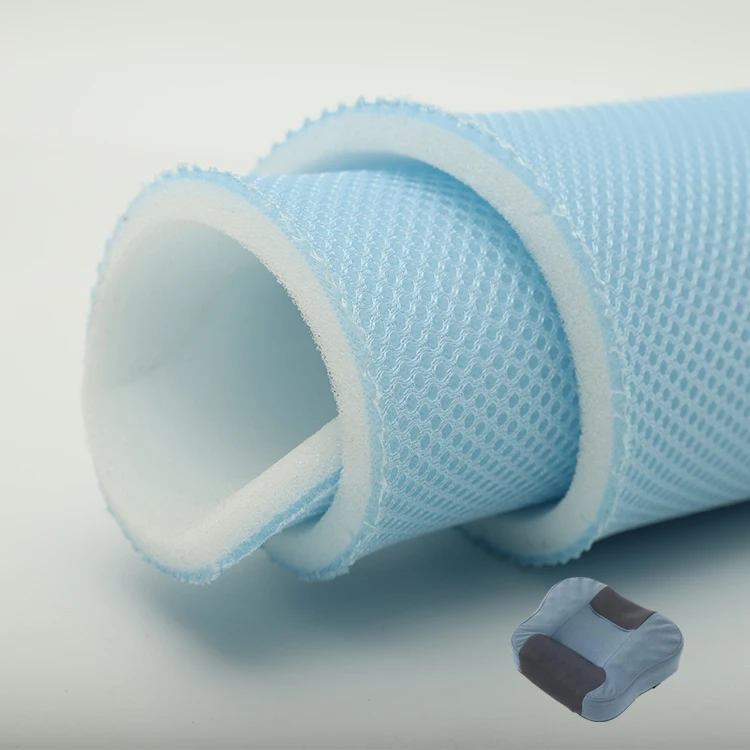

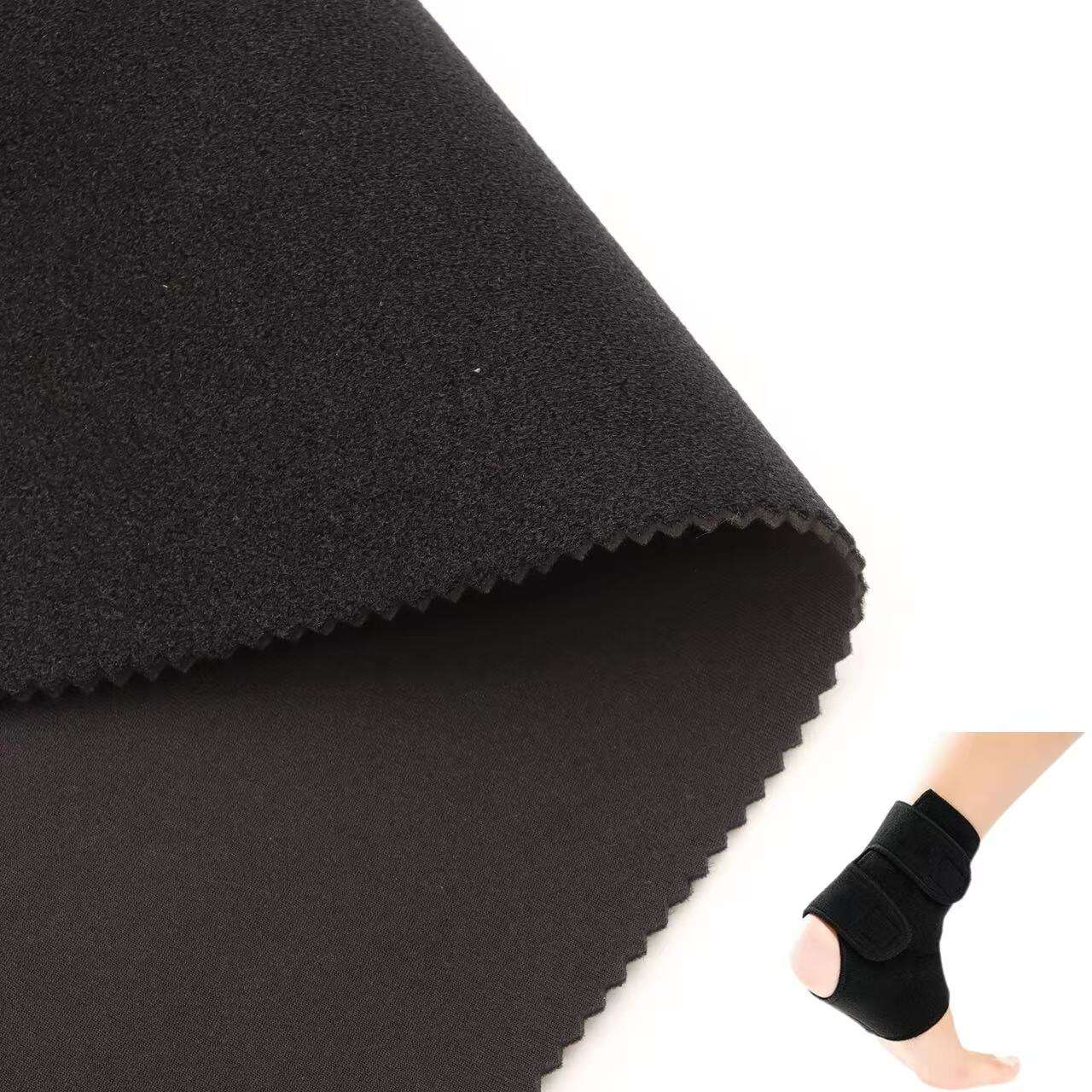

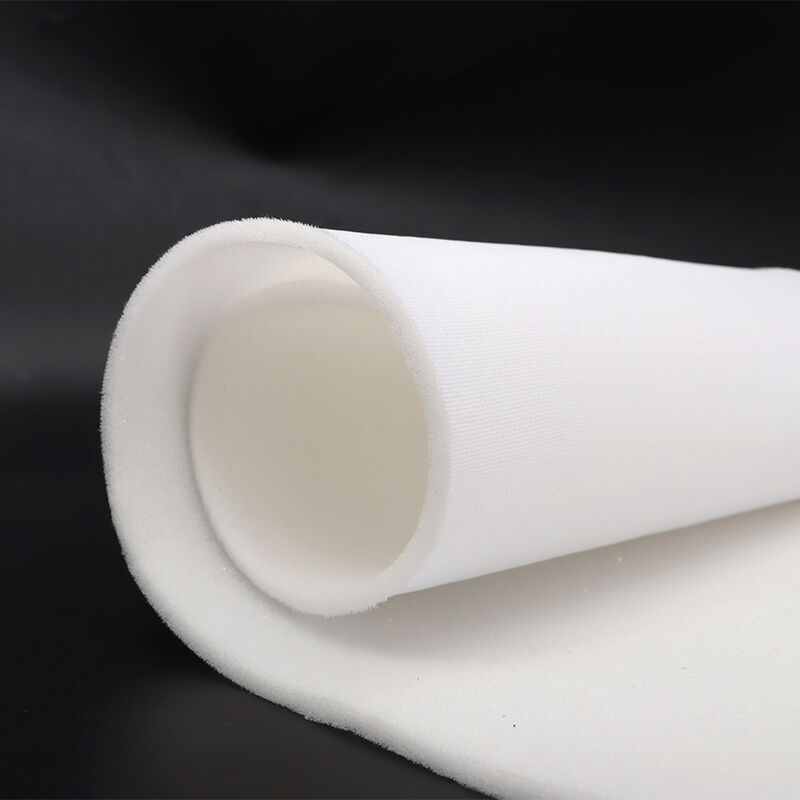

Custom laminated foam fabric represents a revolutionary advancement in textile engineering, combining the durability of traditional fabrics with the exceptional comfort and insulation properties of foam materials. This innovative composite material consists of multiple layers precisely bonded together through a sophisticated lamination process, creating a versatile product that serves various industrial and commercial applications. The fabric's structure typically includes a high-quality outer textile layer, a specialized foam core, and a backing material, all united through advanced adhesive technology. The foam core can be customized in density and thickness to meet specific requirements, while the outer fabric layer can be selected from a range of materials including polyester, nylon, or natural fibers. This customization capability allows manufacturers to create products that perfectly match their intended use, whether it's for automotive interiors, medical equipment, or sporting goods. The lamination process ensures superior dimensional stability and prevents delamination, while maintaining the fabric's breathability and moisture-wicking properties. Additionally, the material can be engineered to provide specific performance characteristics such as fire resistance, water repellency, or enhanced durability, making it an ideal choice for demanding applications.