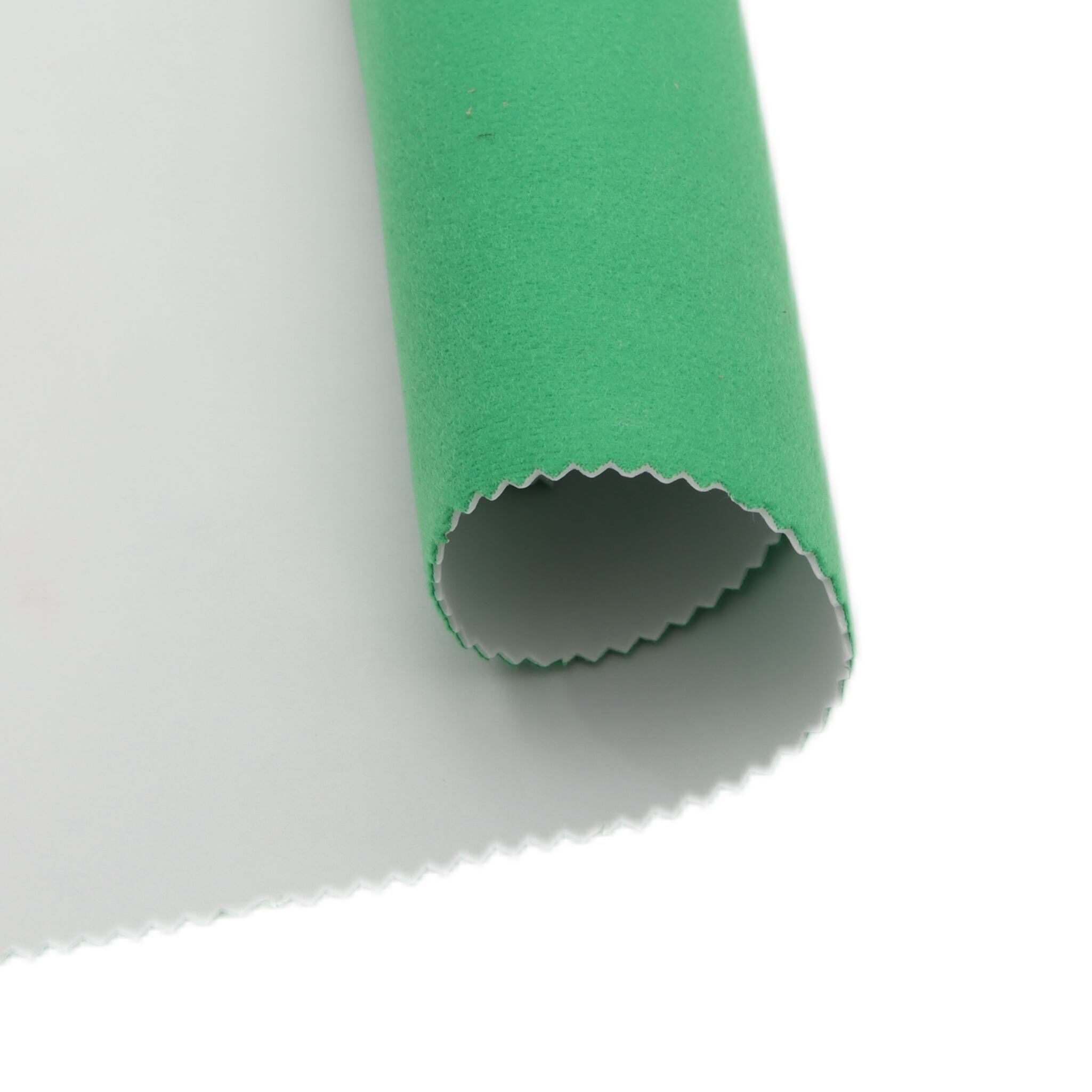

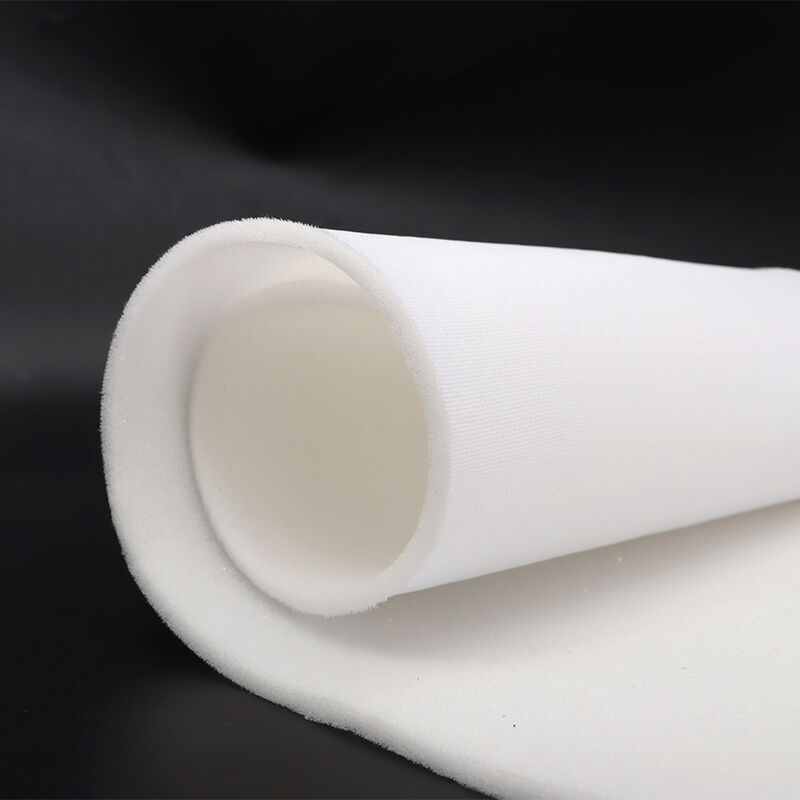

laminated foam fabric factory china

A laminated foam fabric factory in China represents a cutting-edge manufacturing facility specializing in the production of high-quality composite materials that combine foam and fabric through advanced lamination processes. These facilities utilize state-of-the-art equipment and technology to create versatile materials used across multiple industries. The manufacturing process involves precisely bonding foam layers to various fabric types, creating products with enhanced durability, comfort, and functionality. The factories employ sophisticated quality control systems and automated production lines to ensure consistent product quality. They typically offer customization options in terms of foam density, fabric type, thickness, and surface treatment to meet specific customer requirements. The facilities often maintain research and development departments focused on innovative solutions and new product development. Their production capabilities usually include various lamination techniques such as flame lamination, hot-melt adhesive lamination, and spray adhesive lamination, allowing for diverse product applications. These factories commonly serve industries including automotive, furniture, sportswear, medical supplies, and technical textiles, providing materials that meet international quality standards and environmental regulations.