poly laminated foam

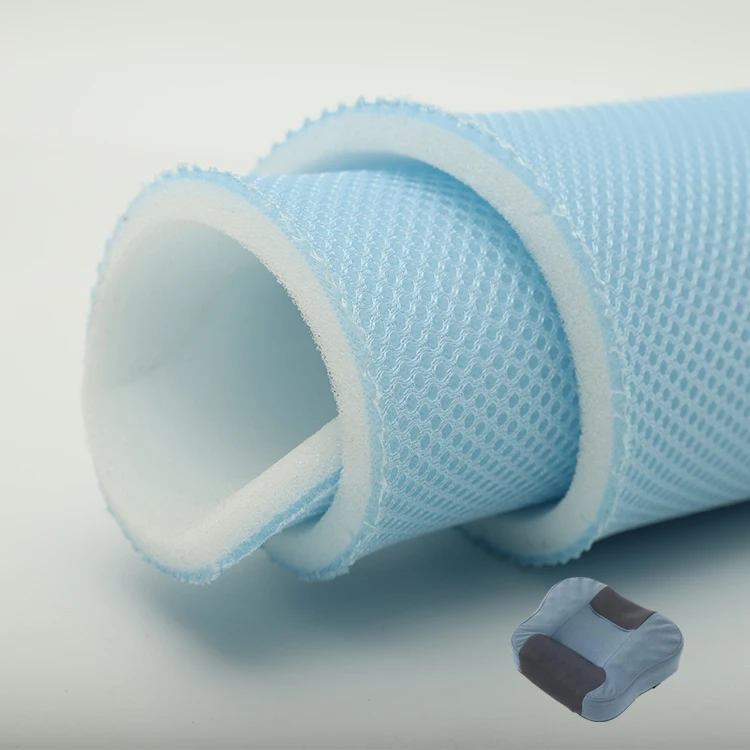

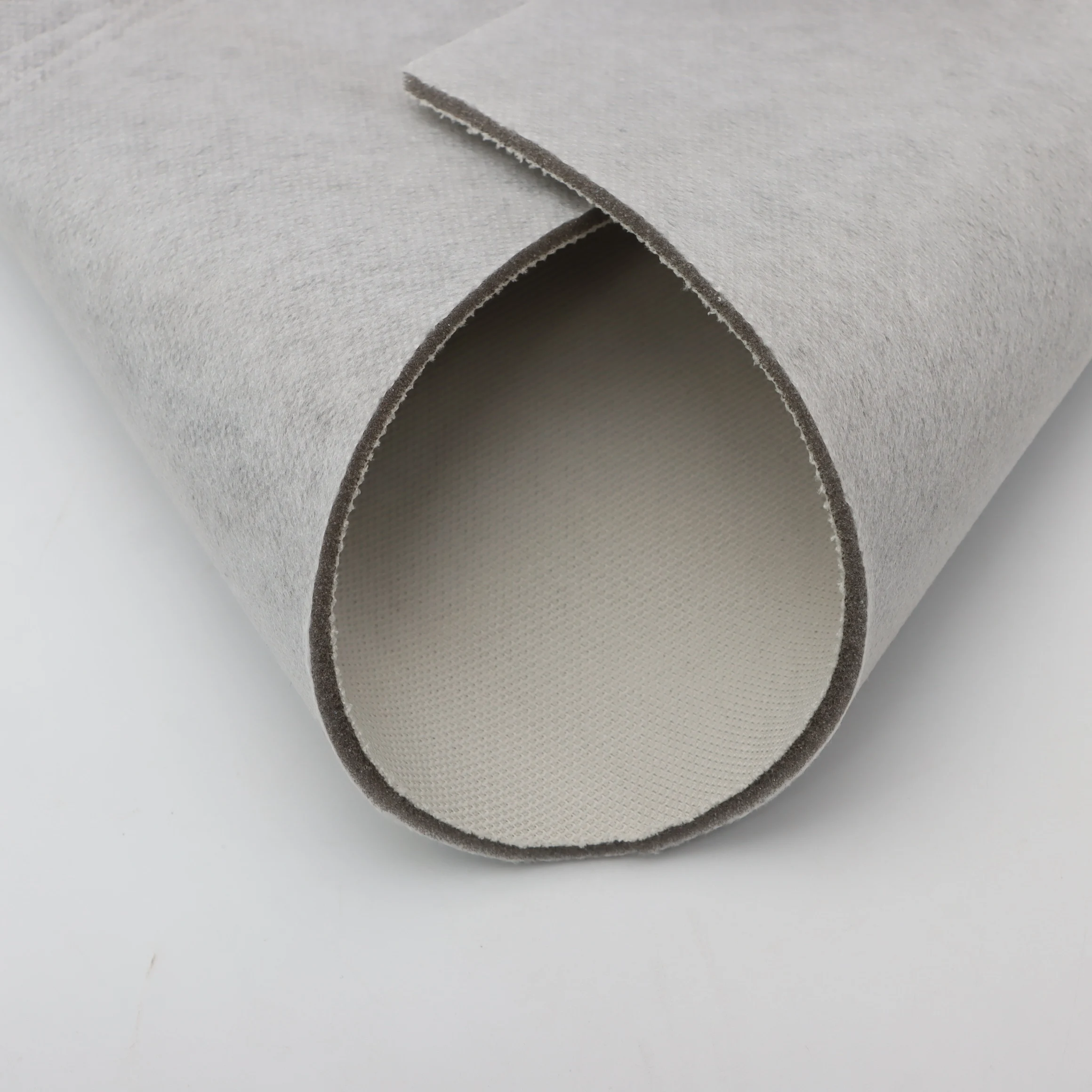

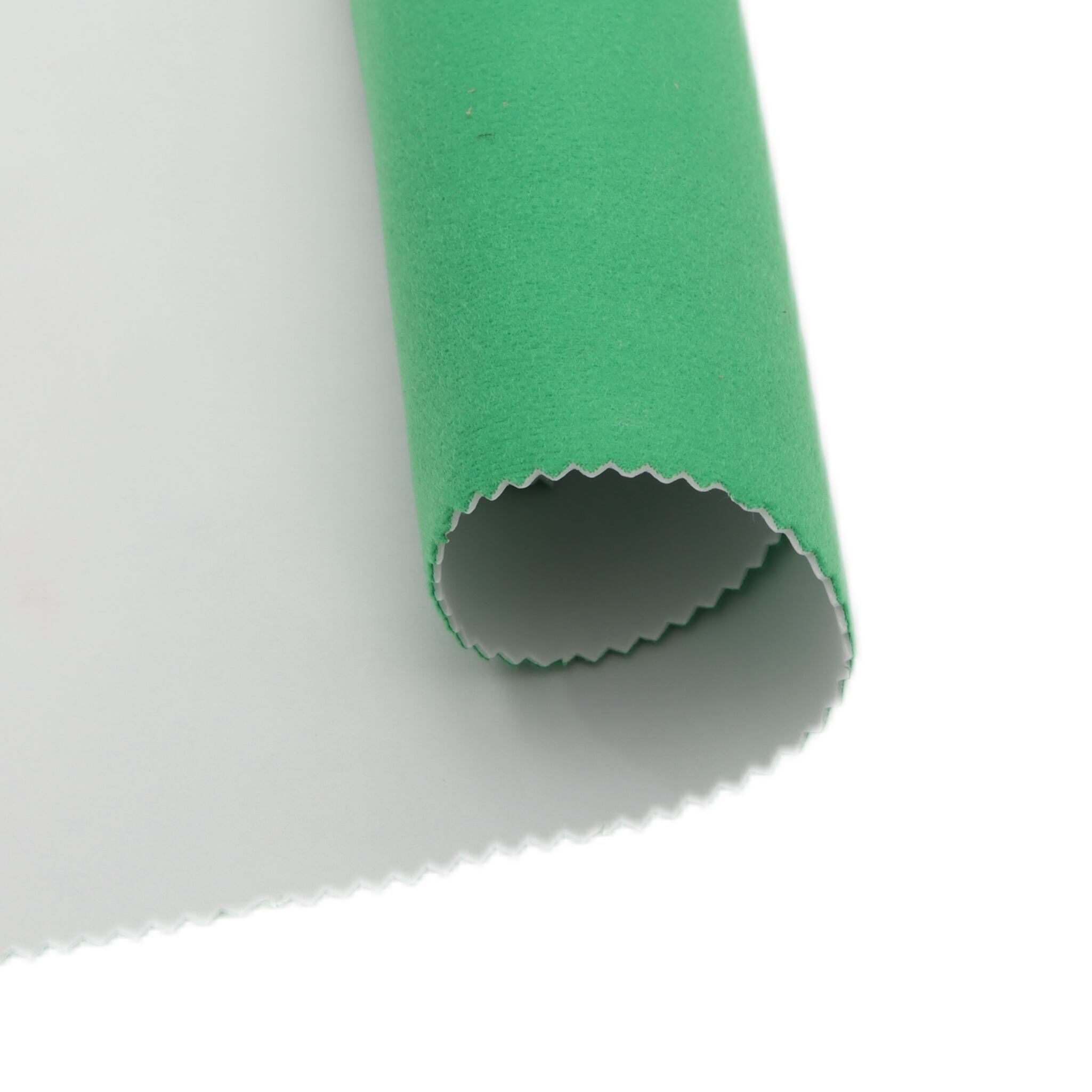

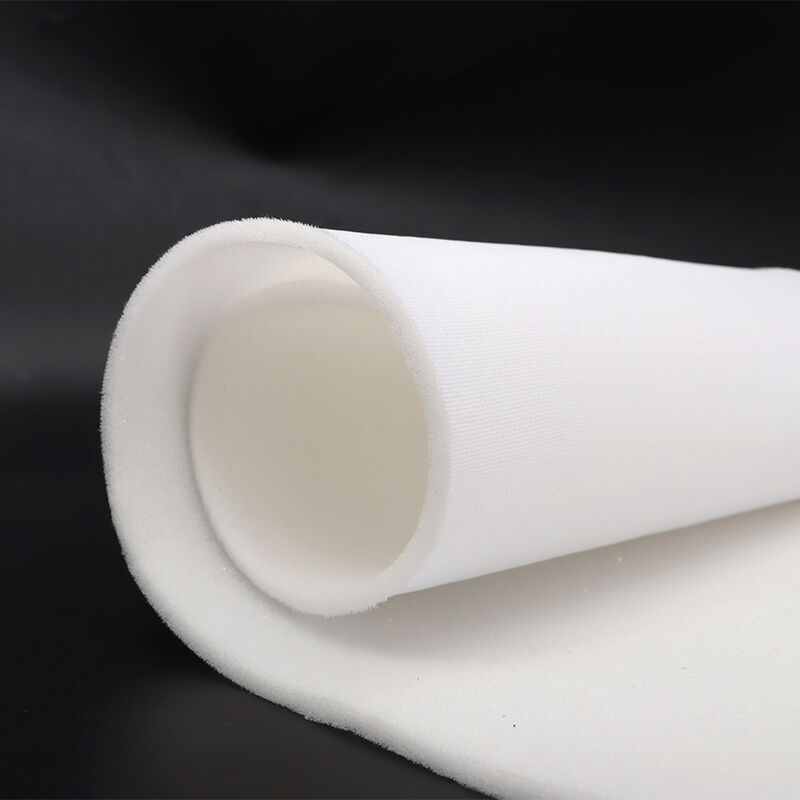

Poly laminated foam represents a versatile and advanced composite material that combines the protective qualities of foam with the durability of polymer lamination. This engineered material consists of a foam core that's precisely bonded with a polymer layer, creating a robust barrier against moisture, chemicals, and physical damage. The manufacturing process involves carefully controlling temperature and pressure to achieve optimal adhesion between the foam substrate and the polymer film, resulting in a seamless and durable composite. The foam core provides excellent cushioning and insulation properties, while the polymer lamination adds structural integrity and environmental resistance. This combination makes it particularly valuable in applications requiring both protection and durability. The material exhibits superior tear resistance, enhanced moisture barrier properties, and exceptional dimensional stability across varying environmental conditions. Its closed-cell structure prevents water absorption and maintains its protective qualities even under challenging conditions. The material's versatility allows it to be manufactured in various densities and thicknesses, making it suitable for diverse applications ranging from packaging and construction to automotive and medical industries. The polymer lamination can be customized with different surface finishes, colors, and textures to meet specific aesthetic and functional requirements.