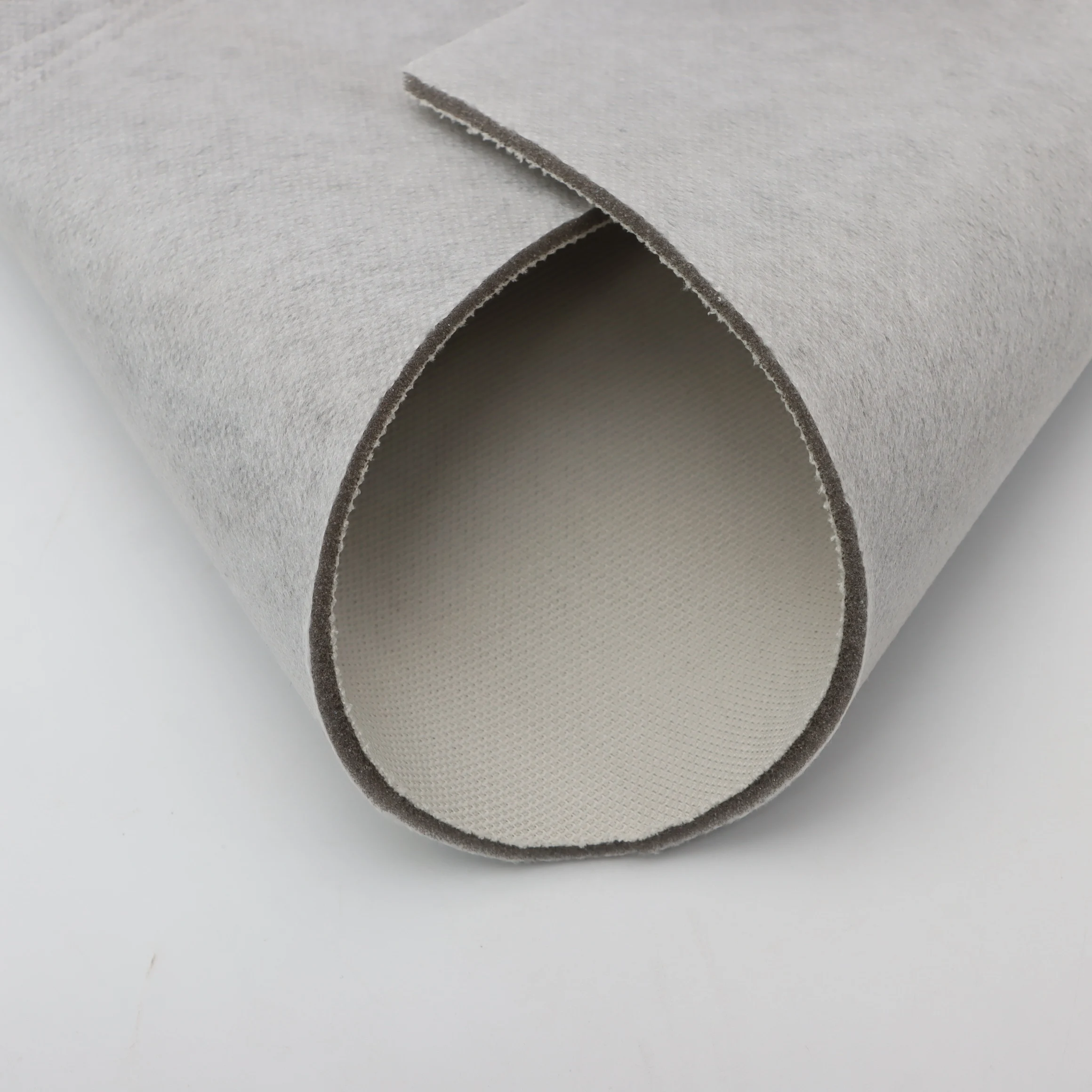

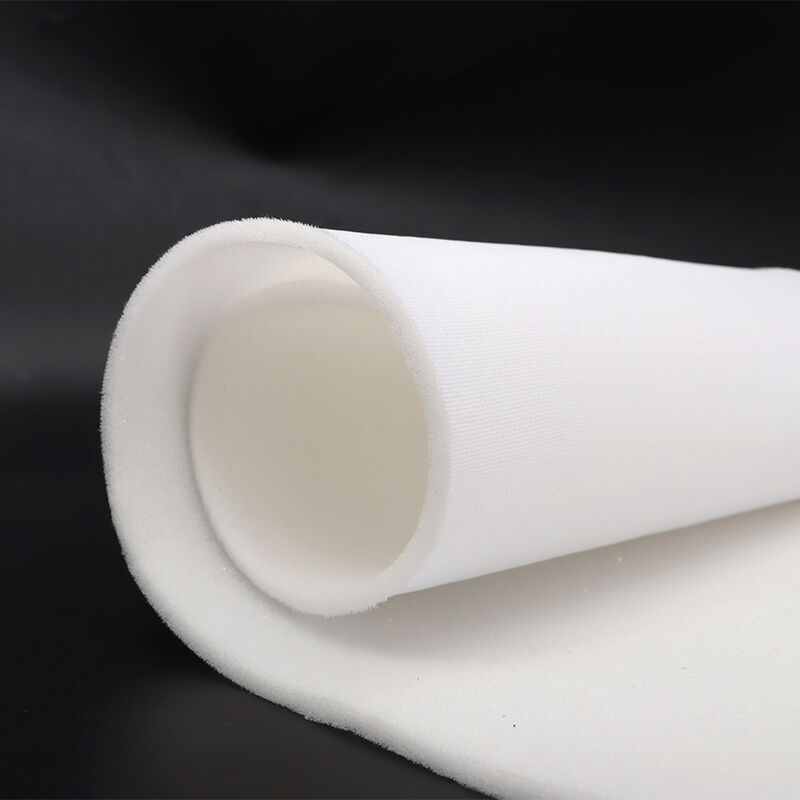

foam laminated fabric

Foam laminated fabric represents a revolutionary advancement in textile engineering, combining the durability of traditional fabrics with the exceptional comfort and insulation properties of foam materials. This innovative composite material is created through a sophisticated bonding process where a layer of foam is permanently adhered to one or both sides of a base fabric. The resulting material offers superior thickness, enhanced durability, and improved thermal insulation characteristics. The foam layer can vary in density and thickness, allowing manufacturers to customize the material's properties for specific applications. The technology behind foam laminated fabric ensures a strong bond between the layers while maintaining flexibility and breathability. These materials are engineered to withstand repeated use and washing cycles without delamination, making them ideal for both commercial and consumer applications. The foam lamination process can be applied to various base fabrics, including cotton, polyester, and blended materials, creating versatile solutions for different industries. This adaptability has made foam laminated fabric a preferred choice in automotive upholstery, medical supplies, sportswear, and protective equipment manufacturing.