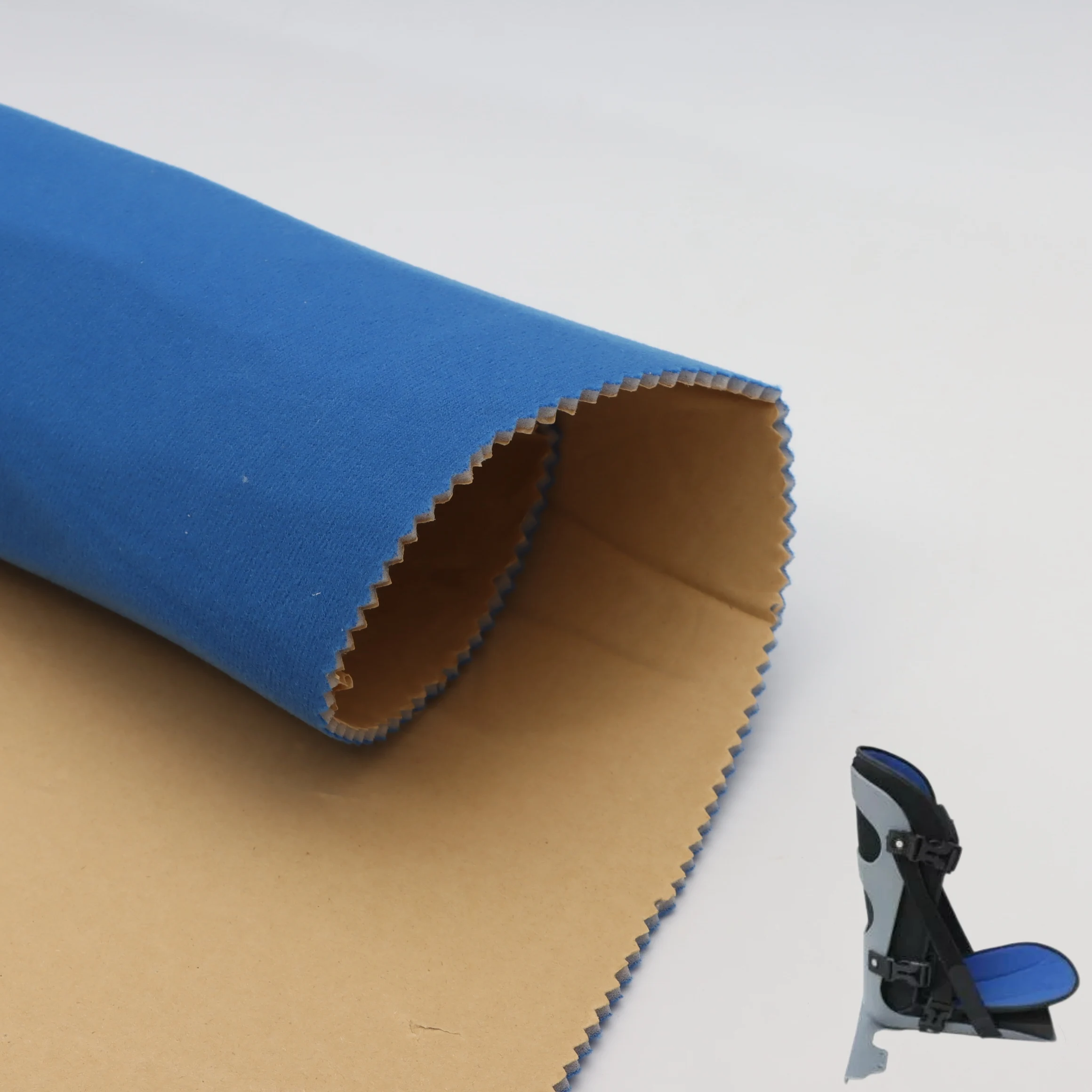

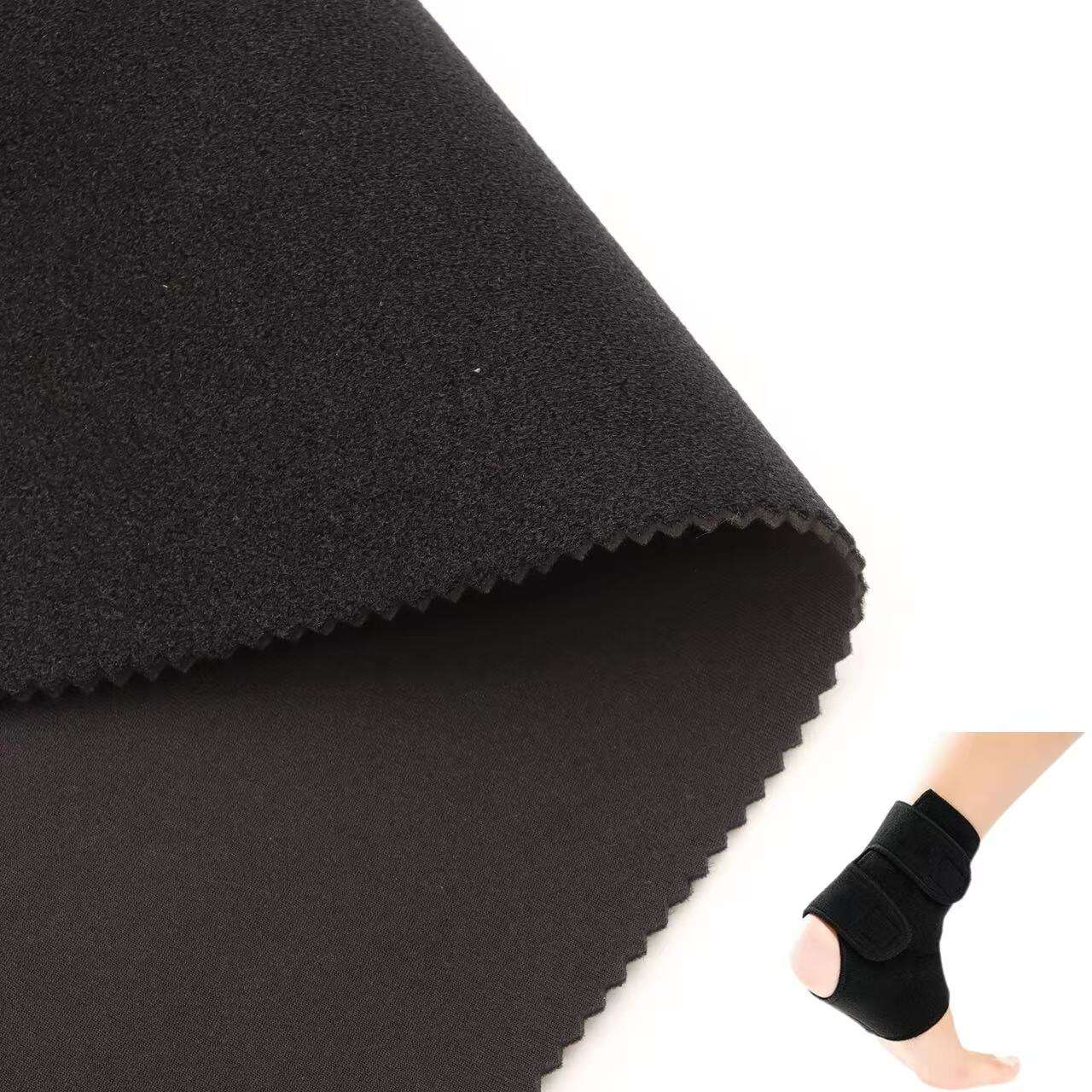

poly laminate foam fabric

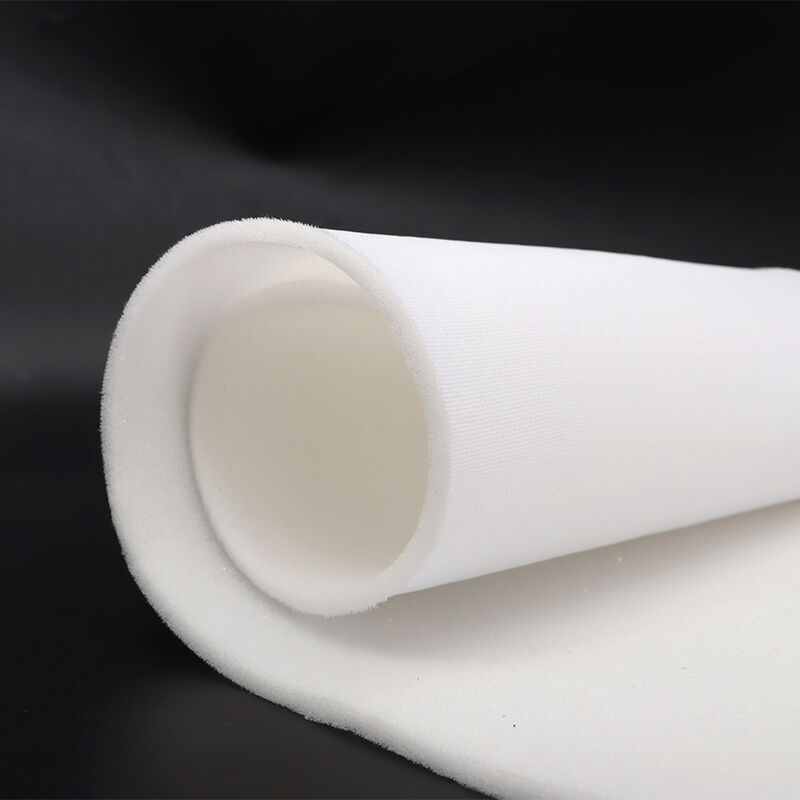

Poly laminate foam fabric represents a cutting-edge composite material that combines the durability of polymer laminates with the cushioning properties of foam and the comfort of fabric. This innovative material consists of three distinct layers: a polyester or polyurethane laminate surface, a foam core, and a fabric backing, all bonded together through advanced thermal or chemical processes. The resulting material offers exceptional moisture resistance, thermal insulation, and structural integrity while maintaining flexibility and comfort. The foam core provides excellent shock absorption and padding, while the laminate layer ensures waterproofing and durability. The fabric backing adds comfort and aesthetic appeal, making it suitable for various applications. This versatile material finds extensive use in outdoor furniture, marine upholstery, medical equipment padding, automotive interiors, and protective gear. Its unique construction allows for customization in terms of thickness, density, and surface finish, meeting diverse industry requirements. The material's inherent properties make it resistant to mold, mildew, and various environmental factors, ensuring longevity and maintaining its appearance over time.