Understanding Medical-Grade Fastening Solutions for Orthopedic Support

The healthcare industry demands reliable, comfortable, and adjustable fastening solutions for medical braces and orthopedic supports. Nylon hook and loop fasteners have revolutionized the way medical braces are designed and used, offering superior functionality and patient comfort. These specialized fastening systems combine durability with gentle contact against the skin, making them ideal for various medical applications.

Medical professionals worldwide rely on high-quality nylon hook and loop closures to ensure their patients receive optimal support while maintaining the ability to make quick adjustments as needed. The integration of OK fabric technology has further enhanced these fastening solutions, providing improved durability and comfort for patients requiring long-term brace wear.

Essential Properties of Medical-Grade Hook and Loop Systems

Material Composition and Design Features

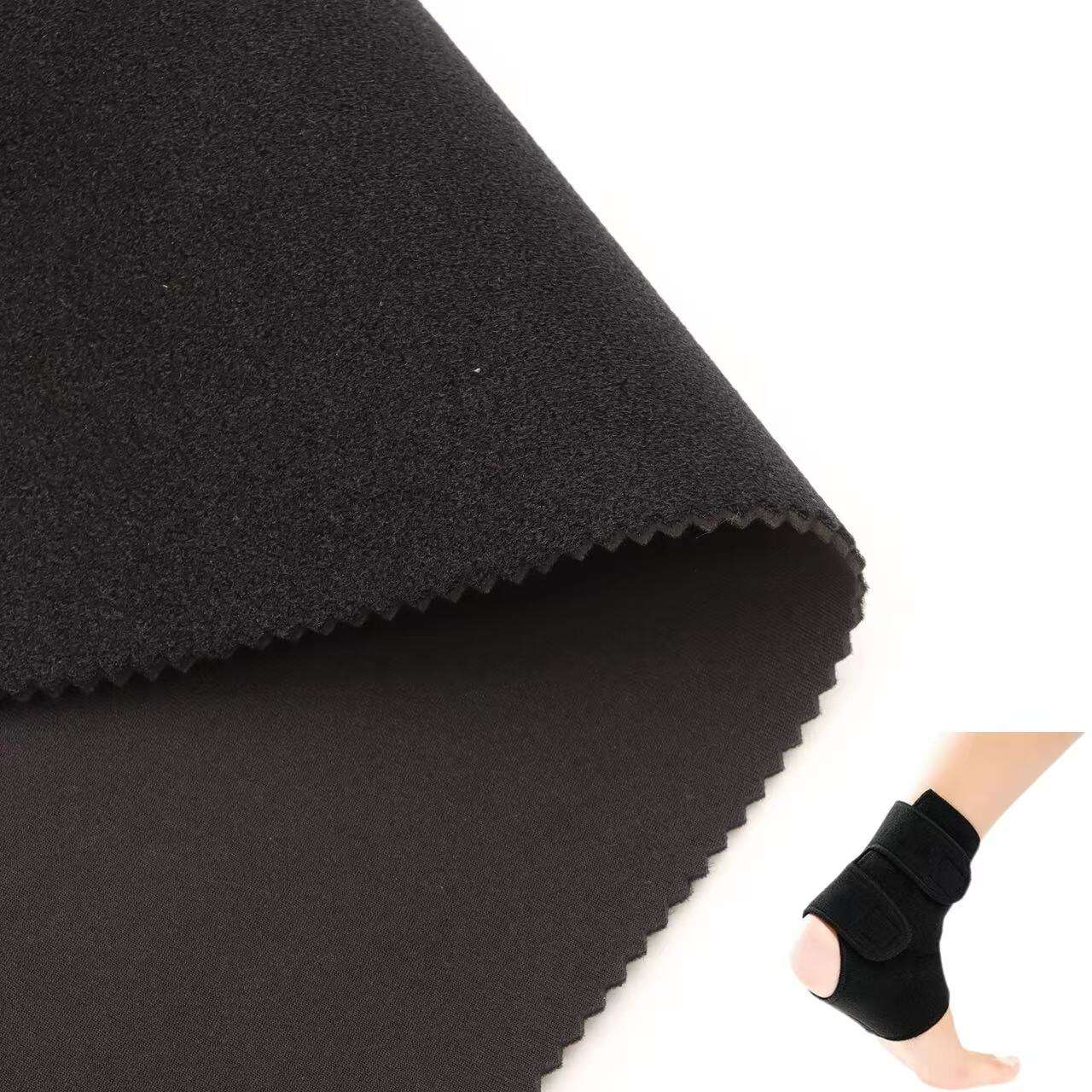

Medical-grade nylon hook and loop fasteners are engineered with specific characteristics that set them apart from standard varieties. The nylon hook component features precisely shaped microscopic hooks that are designed to engage securely with the loop side while minimizing damage to the fabric over repeated use. The loop portion incorporates OK fabric technology, which creates a dense field of loops that maintain their structure even after thousands of attachment cycles.

The material composition includes medical-grade nylon fibers that undergo specialized treatment to enhance their hypoallergenic properties. This ensures that patients with sensitive skin can wear braces for extended periods without experiencing adverse reactions. The durability of these materials also means they can withstand regular cleaning and sterilization procedures without degrading.

Performance Standards and Safety Requirements

Medical brace manufacturers must adhere to strict quality standards when incorporating nylon hook and loop fasteners. These components undergo rigorous testing for tensile strength, shear resistance, and cycle durability. The materials must maintain their performance characteristics even after exposure to various environmental conditions, including moisture, temperature changes, and common medical solutions.

Safety certification processes ensure that the nylon hook and loop materials meet biocompatibility requirements and are free from harmful substances. This includes testing for cytotoxicity, skin irritation, and sensitization to guarantee patient safety during prolonged contact with the skin.

Applications in Different Types of Medical Braces

Orthopedic Support Devices

Orthopedic braces utilize nylon hook and loop fasteners extensively for their adjustability and secure fit. Knee braces, ankle supports, and wrist stabilizers particularly benefit from these closure systems. The ability to achieve precise tension levels helps medical practitioners ensure optimal support while allowing patients to make minor adjustments for comfort throughout the day.

The integration of OK fabric technology in these applications has significantly improved patient compliance by providing a more comfortable wearing experience. The material's breathability and moisture-wicking properties help prevent skin irritation, while the secure closure ensures the brace remains properly positioned during physical activity.

Spinal and Posture Support Systems

Back braces and posture correctors represent another crucial application for medical-grade nylon hook and loop fasteners. These devices often require multiple adjustment points to achieve proper spinal alignment and support. The strong holding power of the hook and loop system ensures that the brace maintains its therapeutic position while allowing for natural movement.

The durability of nylon hook and loop closures is particularly important in these applications, as back braces often face significant stress during daily activities. The OK fabric component helps distribute pressure evenly, reducing the risk of localized stress points that could cause discomfort or compromise the brace's effectiveness.

Maintenance and Care Considerations

Cleaning and Sanitization Protocols

Proper maintenance of medical braces with nylon hook and loop fasteners is essential for both hygiene and longevity. Healthcare facilities typically implement specific cleaning protocols that preserve the integrity of the fastening system while ensuring proper sanitization. This includes using appropriate cleaning agents that effectively remove contaminants without degrading the hook and loop material.

Regular inspection and cleaning of the hook and loop surfaces help prevent the accumulation of debris that could compromise their performance. The OK fabric technology incorporated into these fasteners facilitates easier cleaning while maintaining its structural integrity even after repeated washing cycles.

Longevity and Replacement Guidelines

Medical facilities must establish clear guidelines for monitoring the condition of nylon hook and loop fasteners on braces. Regular assessment of the closure strength and material integrity helps determine when replacement is necessary. The superior durability of medical-grade hook and loop systems typically allows for extended use periods, but factors such as frequency of use and cleaning methods can impact their lifespan.

Healthcare providers should document the wear patterns and performance characteristics of these fastening systems to optimize replacement schedules and ensure consistent therapeutic benefits for patients. The incorporation of OK fabric technology has significantly extended the service life of these components, reducing the frequency of replacements and associated costs.

Future Innovations and Developments

Advanced Material Technologies

The medical brace industry continues to invest in research and development to enhance nylon hook and loop fastening systems. Emerging technologies focus on improving antimicrobial properties, reducing material weight, and enhancing comfort while maintaining or exceeding current performance standards. These innovations promise to further optimize the patient experience and treatment outcomes.

New manufacturing processes are being developed to create more environmentally sustainable options without compromising the medical-grade requirements. This includes exploring bio-based materials and recycling solutions that align with healthcare facilities' increasing focus on sustainability initiatives.

Smart Integration and Monitoring

The future of medical braces incorporating nylon hook and loop fasteners includes the integration of smart technologies. These developments may include sensors embedded within the fastening system to monitor pressure distribution, wear patterns, and patient compliance. Such innovations could provide valuable data to healthcare providers while ensuring optimal brace performance.

Research is also underway to develop hook and loop systems that can adapt to changes in patient needs throughout the day, potentially incorporating shape-memory materials or responsive tension systems that enhance therapeutic benefits.

Frequently Asked Questions

How often should medical brace fasteners be inspected?

Medical professionals recommend inspecting nylon hook and loop fasteners on braces before each use. For devices used daily, a thorough inspection should be conducted at least weekly to check for signs of wear, contamination, or reduced closure strength. Regular monitoring helps ensure optimal performance and patient safety.

What makes medical-grade hook and loop different from standard versions?

Medical-grade nylon hook and loop fasteners are manufactured under strict quality control standards, using hypoallergenic materials that meet biocompatibility requirements. They undergo specialized treatments to enhance durability, maintain closure strength after multiple uses, and withstand medical-grade cleaning procedures.

Can nylon hook and loop fasteners be sterilized?

Yes, medical-grade nylon hook and loop fasteners can withstand various sterilization methods, including autoclave procedures and chemical sterilization. However, specific protocols must be followed to maintain the material's integrity and performance characteristics. Healthcare facilities should consult manufacturer guidelines for recommended sterilization procedures.