pu foam laminated fabric

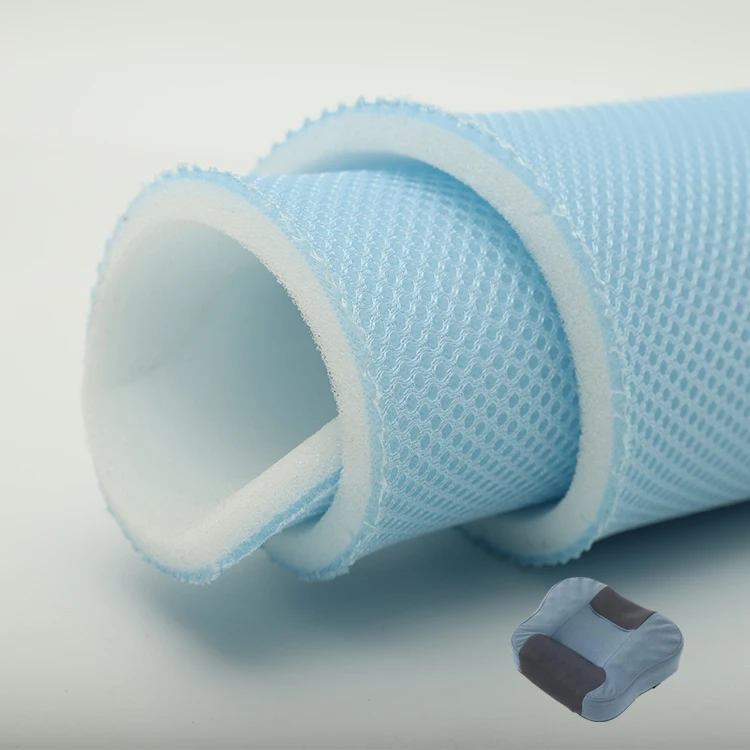

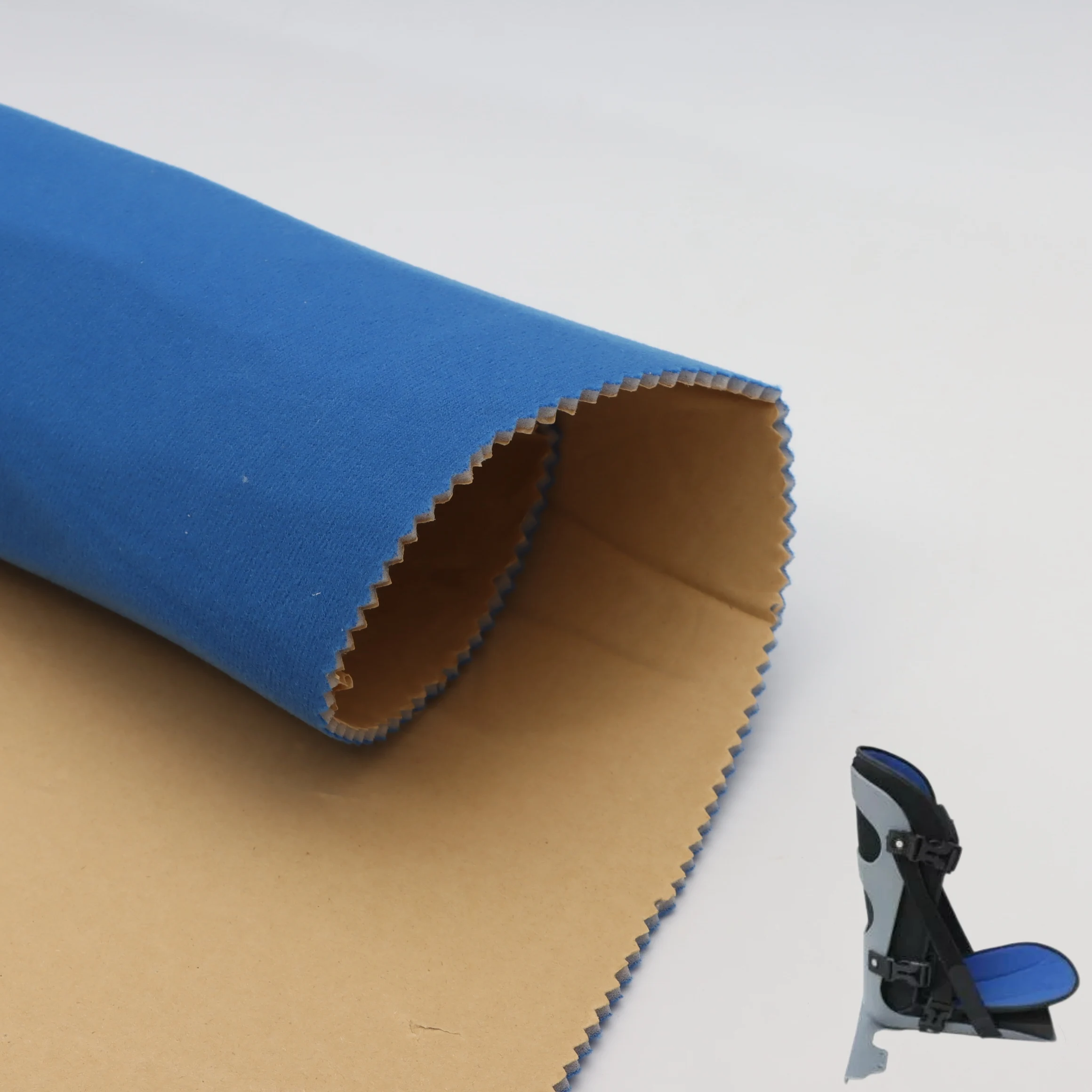

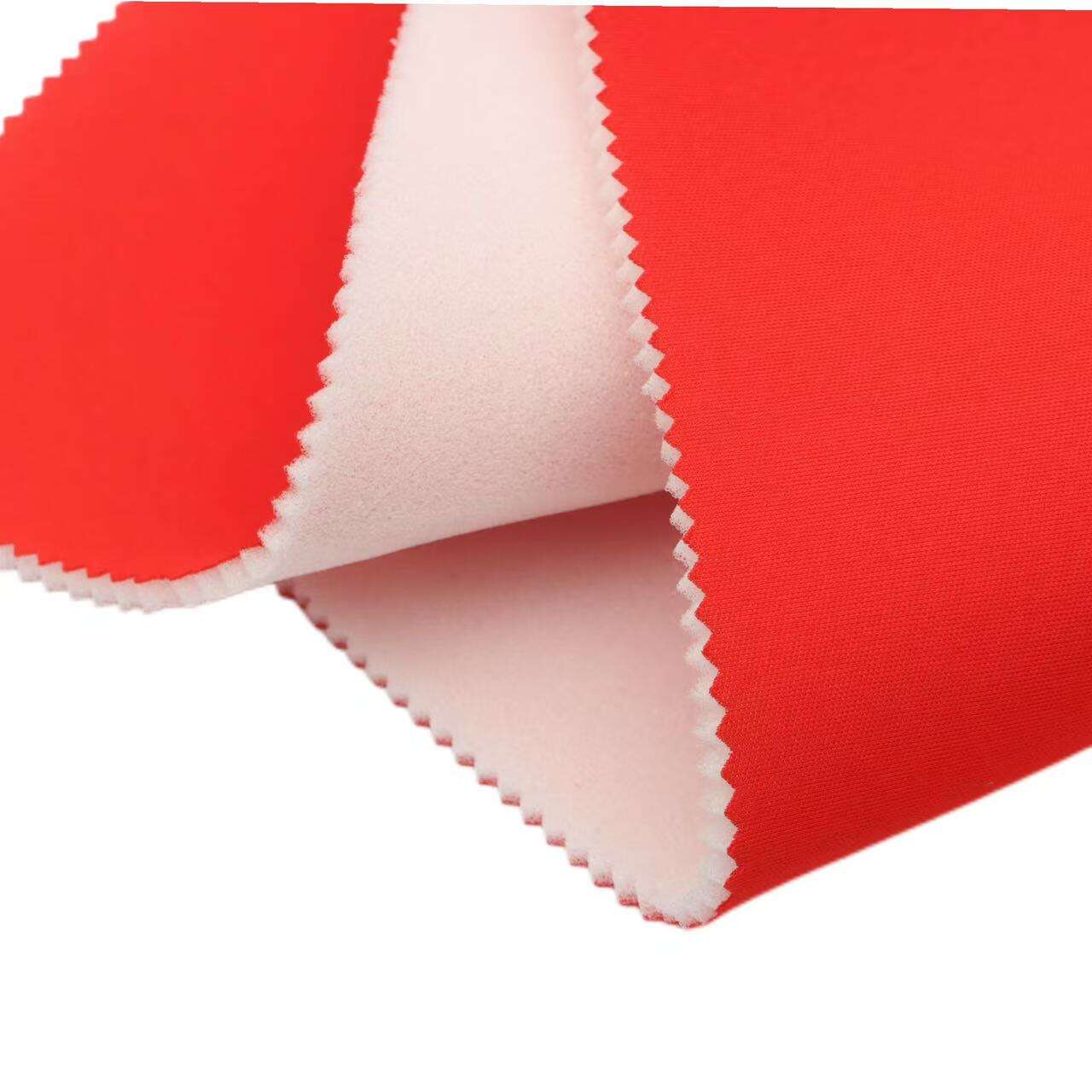

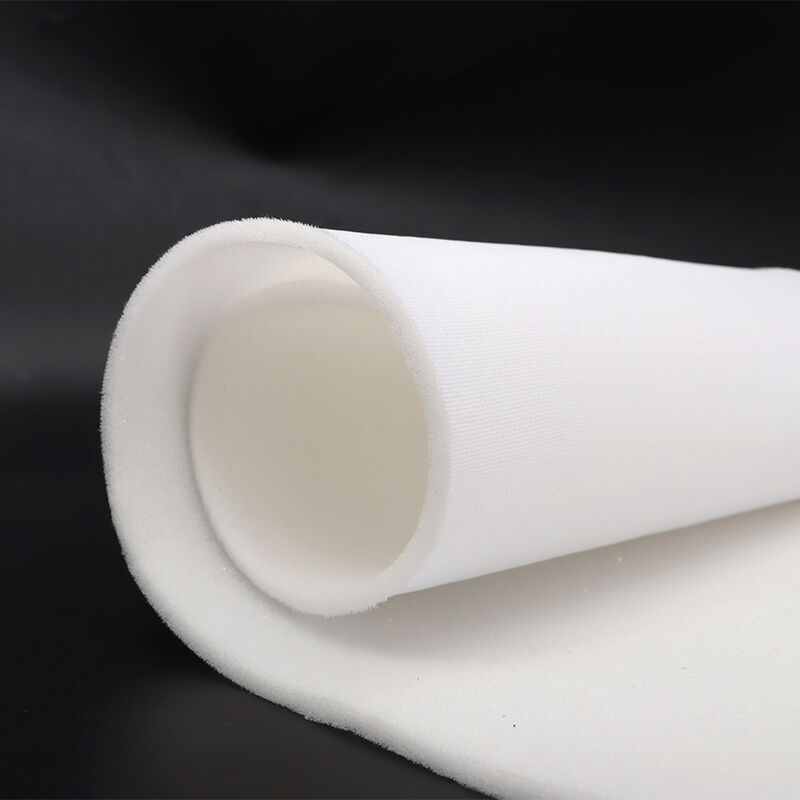

PU foam laminated fabric represents an innovative composite material that combines polyurethane foam with various textile substrates through an advanced lamination process. This versatile material features a three layer structure: a textile face fabric, a middle layer of polyurethane foam, and a backing fabric. The manufacturing process involves bonding these layers using heat and pressure, creating a durable and functional material. The resulting fabric offers exceptional comfort, insulation, and protection properties. The polyurethane foam core provides excellent cushioning and thermal regulation, while the outer textile layers contribute to durability and aesthetic appeal. This engineered fabric finds extensive applications across multiple industries, including automotive upholstery, furniture manufacturing, sports equipment, and protective gear. The material's structure allows for customization in terms of foam density, thickness, and fabric selection, enabling manufacturers to meet specific performance requirements. Additionally, the fabric demonstrates remarkable resistance to wear and tear, maintaining its structural integrity even under frequent use. Modern manufacturing techniques ensure consistent quality and precise control over the lamination process, resulting in a product that combines functionality with longevity.