How Foam Lamination Enhances Comfort in Lingerie Design

Lingerie is more than just clothing—it is a combination of fashion, function, and comfort. One of the most critical aspects of modern lingerie design is ensuring that garments fit perfectly while providing support and softness. Foam lamination has emerged as a key technique in achieving this balance. By integrating foam layers into textile fabrics, lingerie designers can enhance comfort, improve shape retention, and provide subtle support without compromising aesthetics. This article explores how foam lamination works, its benefits, applications in lingerie, and future trends in the industry.

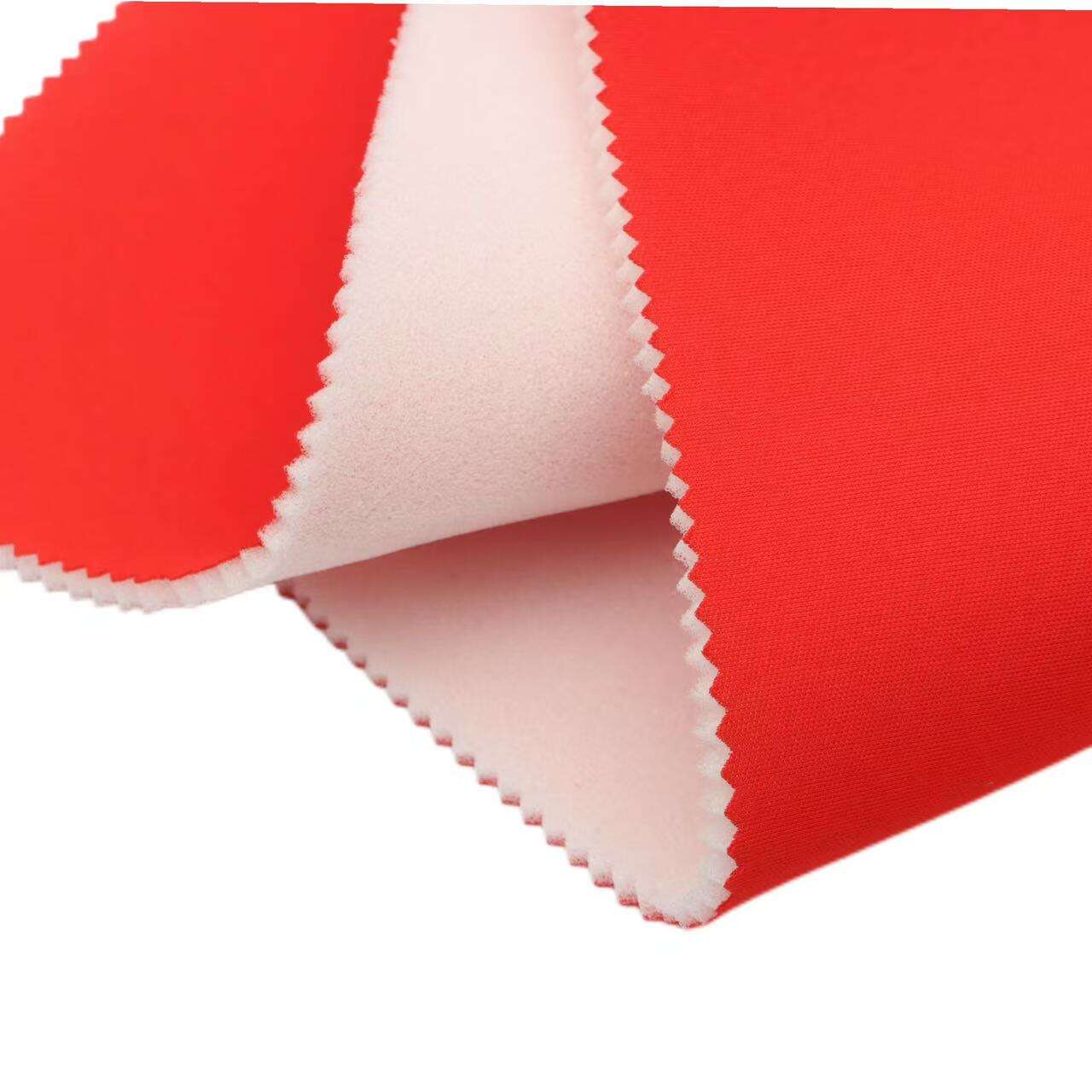

Understanding Foam Lamination

Foam lamination is a process in which a thin layer of foam is bonded to a fabric using heat, adhesive, or pressure. This creates a composite material that combines the softness of foam with the texture, appearance, and flexibility of the fabric. Depending on the type of foam and fabric used, designers can achieve various levels of cushioning, elasticity, and support.

The foam layer can be made from polyurethane, EVA, or memory foam variants, each offering unique properties. When laminated to fabrics like cotton, nylon, polyester, or blends, foam provides structure without adding excessive bulk. This is particularly important in lingerie, where the goal is to create garments that are barely noticeable while still offering shape and support.

Importance of Comfort in Lingerie

Comfort is a top priority in lingerie design. Lingerie must conform to the body, move with it, and remain breathable while providing necessary support. Poorly designed lingerie can cause skin irritation, restrict movement, or create unflattering shapes. Foam lamination addresses these issues by offering a soft, flexible layer that cushions the skin, distributes pressure evenly, and prevents friction.

Comfort is especially crucial for underwire bras, padded bras, and shapewear. Foam lamination allows these garments to maintain their shape while remaining lightweight and soft against the skin. The right foam density and lamination technique can significantly improve the overall wearing experience, encouraging daily use without discomfort.

Types of Foam Used in Lingerie Lamination

Polyurethane Foam

Polyurethane foam is widely used in lingerie due to its lightweight and flexible properties. It provides gentle cushioning and molds well to the body’s contours. PU foam can be laminated to stretchable fabrics, offering both support and comfort for bras, camisoles, and shapewear.

Memory Foam

Memory foam offers superior adaptability, molding to the individual shape of the body. This type of foam is ideal for lingerie that requires precise fit and comfort, such as padded bras or contour cups. Memory foam reduces pressure points and ensures that garments conform to the wearer’s curves naturally.

EVA Foam

EVA foam is soft, resilient, and lightweight. It provides moderate support and cushioning, making it suitable for everyday lingerie and casual wear. EVA foam lamination maintains garment shape while allowing freedom of movement.

Laminated Layer Variations

Laminated foam layers can vary in thickness and density depending on the intended purpose. Thinner foams offer subtle shaping and comfort for everyday lingerie, while thicker foams provide more structured support in push-up bras or molded cups. Designers can combine different layers to create zones of compression and softness tailored to the garment’s function.

Benefits of Foam Lamination in Lingerie Design

Enhanced Comfort

Foam lamination creates a soft interface between the body and garment. The foam layer cushions sensitive areas, prevents chafing, and distributes pressure evenly. This makes lingerie more comfortable for long-term wear, especially in areas like the underbust, shoulders, and waist.

Improved Support

Foam lamination provides structural support without relying solely on wires or rigid panels. This allows designers to create bras and shapewear that maintain their shape and support the bust or body contours without sacrificing comfort.

Lightweight and Flexible

Foam-laminated lingerie remains lightweight, allowing for ease of movement. Unlike heavy padding or multiple fabric layers, laminated foam adds minimal weight while providing maximum comfort and support.

Enhanced Fit and Shape Retention

The foam layer helps the garment retain its shape over time, preventing sagging or deformation. This is particularly important for bras and molded cups, which require consistent support and shape throughout use.

Versatility in Design

Foam lamination allows designers to experiment with different fabrics, textures, and garment styles. It can be applied to lace, mesh, microfiber, or stretch fabrics, enabling creative designs while ensuring comfort. Laminated foams can also be combined with adhesive or heat-bonded fabrics to create seamless constructions that reduce irritation and enhance aesthetic appeal.

Moisture Management

Certain foam fabrics are breathable and moisture-wicking, helping to maintain comfort throughout the day. This is essential for lingerie, as these garments are worn close to the skin and need to manage sweat and moisture effectively.

Applications in Lingerie

Padded Bras and Contour Cups

Foam lamination is widely used in padded bras and contour cups to provide shape and subtle lift. Laminated foam molds to the breast, ensuring natural curves and support. The soft foam also prevents pressure points and skin irritation under the cups.

Push-Up Bras

In push-up bras, laminated foam provides additional support and volume. The foam layer can be strategically shaped to enhance lift and cleavage without adding uncomfortable bulk or stiffness.

Shapewear and Control Garments

Shapewear benefits from laminated foam in areas that require gentle compression and smooth contours. Foam lamination provides structure, ensures a snug fit, and prevents digging into the skin while maintaining flexibility for movement.

Wireless Bras and Comfort-Focused Designs

Foam lamination allows for wireless bras that maintain shape and support without metal underwires. The foam layer adds softness and ensures the garment conforms comfortably to the wearer’s body.

Lingerie with Seamless Construction

Seamless lingerie often uses foam lamination to create smooth surfaces without stitching or bulging seams. This improves comfort, prevents irritation, and enhances aesthetic appeal under clothing.

Design Considerations for Foam Lamination

When designing lingerie with foam lamination, it is important to consider foam density, fabric stretch, breathability, and garment purpose. Designers must balance softness with structural integrity to ensure the foam provides support without compromising comfort.

Foam thickness and placement should align with body contours to provide targeted cushioning and shaping. Advanced lamination techniques, such as heat-bonding or adhesive lamination, help create seamless, flexible garments.

Maintenance and Longevity

Foam-laminated lingerie requires proper care to maintain its performance. Gentle hand washing or machine washing on a delicate cycle is recommended to prevent foam compression or delamination. Air drying is preferred to maintain shape and elasticity. Proper care ensures that foam-laminated lingerie retains comfort, support, and aesthetics over time.

Future Trends in Foam Lamination for Lingerie

The future of foam lamination in lingerie design includes sustainable materials, innovative foam structures, and integration with smart textiles. Eco-friendly foams made from recycled or biodegradable materials are gaining popularity. Advances in breathable and moisture-wicking foams improve comfort and hygiene. Designers are also exploring hybrid foams and digital lamination techniques to create customized, body-conforming garments. Smart lingerie may integrate sensors within laminated foam layers to monitor posture, movement, or even biometrics.

Conclusion

Foam lamination has transformed lingerie design by enhancing comfort, support, and aesthetic versatility. From padded and push-up bras to shapewear and seamless constructions, laminated foam provides a lightweight, flexible, and durable solution for modern lingerie. By understanding the types of foam fabric, lamination techniques, and design considerations, lingerie designers can create garments that offer both beauty and comfort, meeting the evolving demands of consumers.

FAQ

What types of foam are commonly used in lingerie lamination?

Polyurethane foam, memory foam, EVA foam, and laminated foam composites are most commonly used for padded and support-focused lingerie designs.

How does foam lamination improve comfort in lingerie?

Foam lamination cushions sensitive areas, distributes pressure evenly, reduces friction, and conforms to body contours for a natural fit.

Can foam lamination be used in wireless bras?

Yes, foam lamination provides structural support without metal underwires, maintaining shape and comfort in wireless designs.

Is foam-laminated lingerie durable?

With proper care, foam-laminated lingerie retains shape, support, and comfort over time, resisting deformation and sagging.

Are there breathable foam options for lingerie?

Yes, many foam fabrics are breathable and moisture-wicking, ensuring comfort and hygiene during prolonged wear.

Table of Contents

- How Foam Lamination Enhances Comfort in Lingerie Design

- Understanding Foam Lamination

- Importance of Comfort in Lingerie

- Types of Foam Used in Lingerie Lamination

- Benefits of Foam Lamination in Lingerie Design

- Applications in Lingerie

- Design Considerations for Foam Lamination

- Maintenance and Longevity

- Future Trends in Foam Lamination for Lingerie

- Conclusion

- FAQ