laminated foam fabric for helmet liners

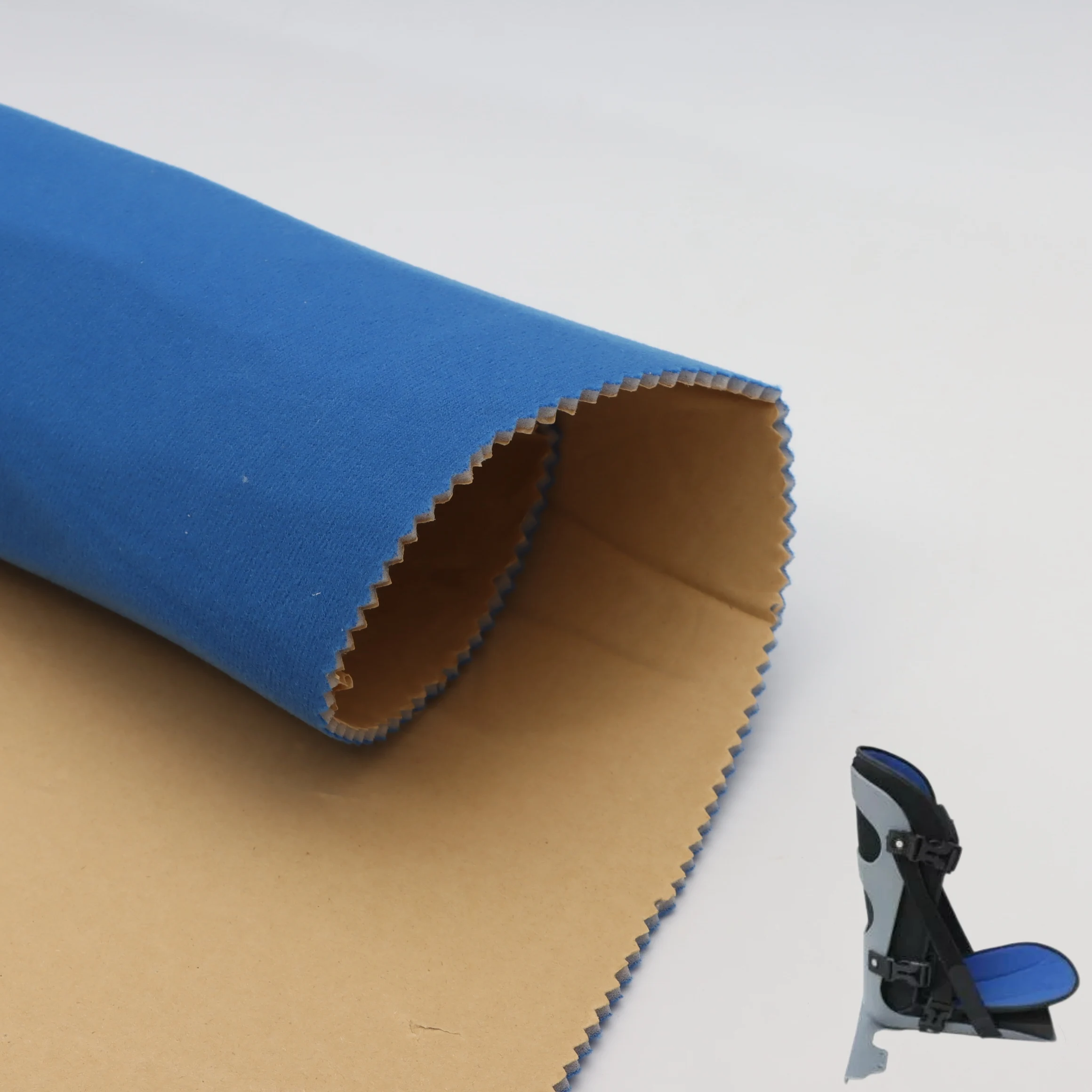

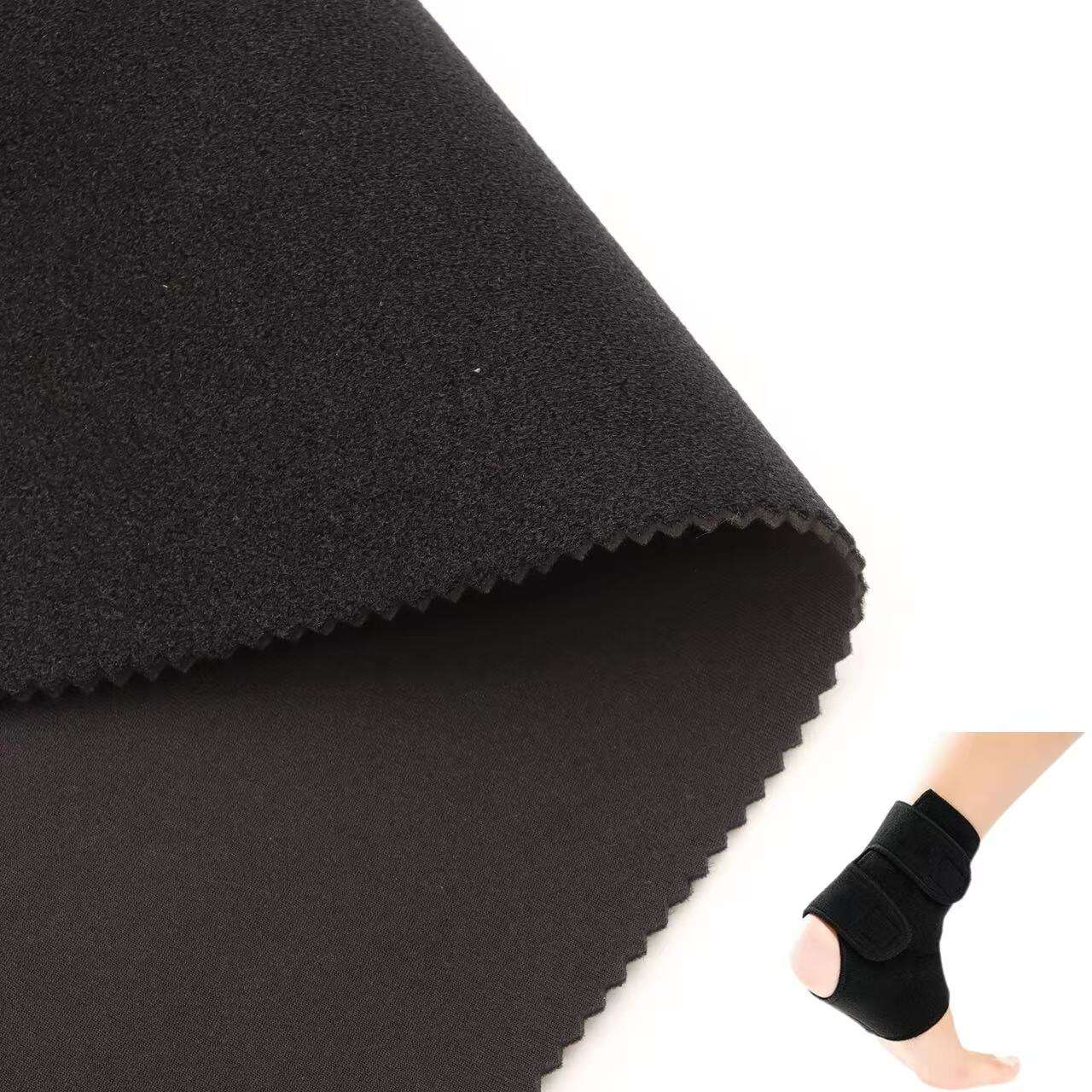

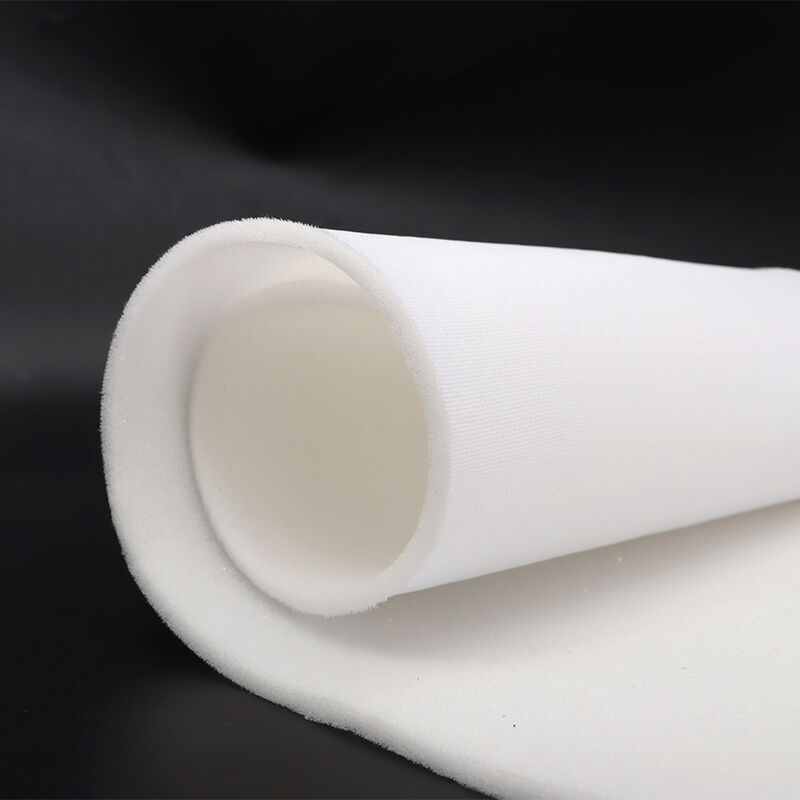

Laminated foam fabric for helmet liners represents a cutting-edge advancement in protective headgear technology, combining multiple layers of specialized materials to create a superior cushioning system. This innovative composite material consists of high-density foam cores laminated with moisture-wicking fabrics, engineered specifically for optimal impact absorption and comfort. The multi-layered structure features strategically placed foam densities that work in concert to dissipate impact forces effectively while maintaining excellent ventilation properties. The fabric's unique lamination process ensures durability and structural integrity, preventing delamination even under intense use conditions. These liners incorporate advanced moisture management technology, utilizing specialized treatments and fabric constructions that actively move perspiration away from the head. The material's innovative design allows for exceptional flexibility and conformability, ensuring a customized fit for various head shapes while maintaining consistent protection levels. Additionally, the laminated construction enables manufacturers to create lighter, more compact helmet designs without compromising safety standards.