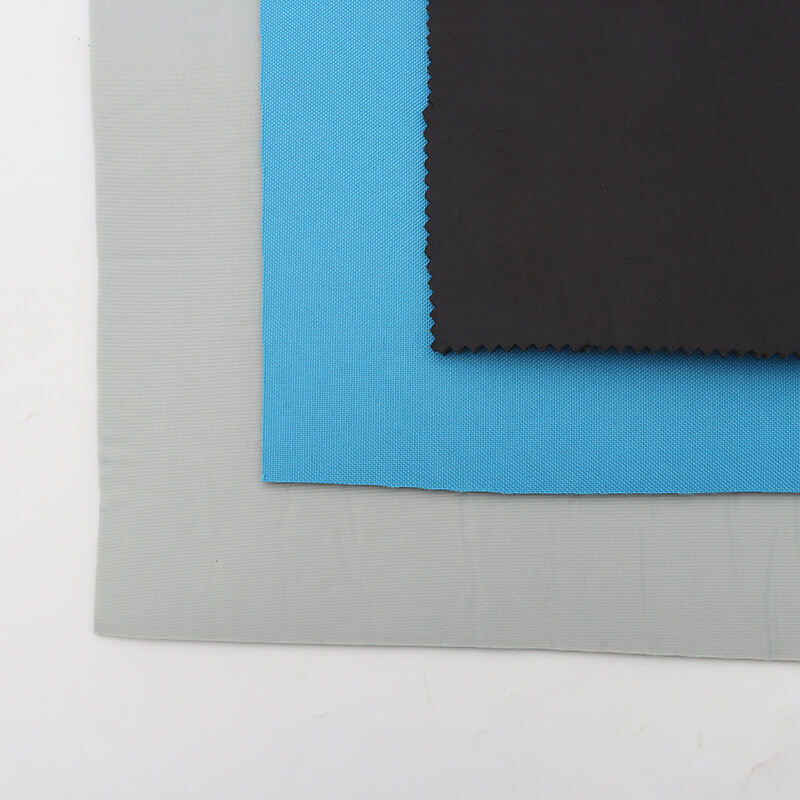

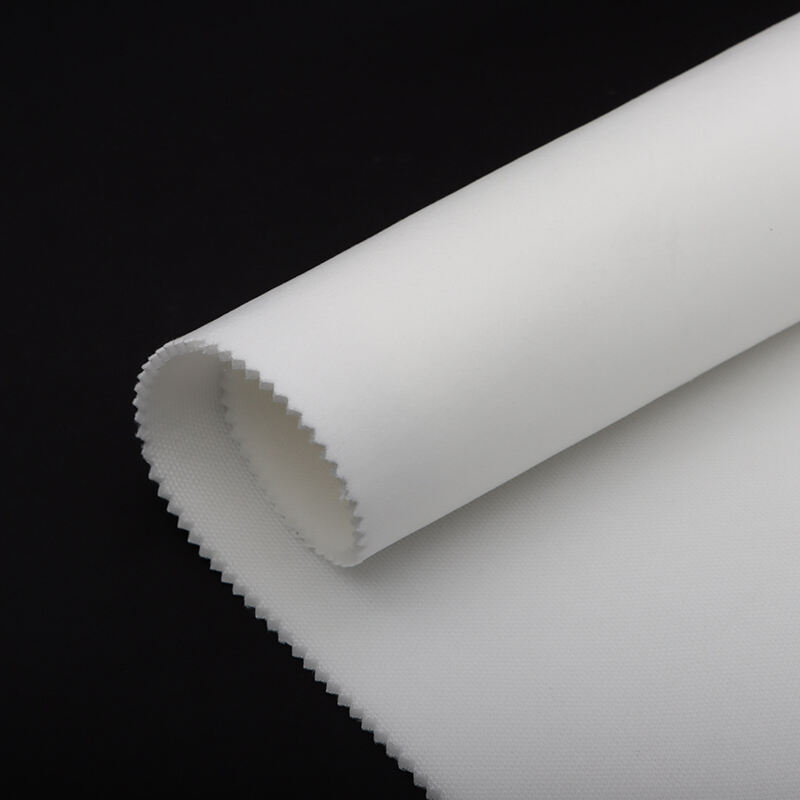

polyester foam material

Polyester foam is a versatile synthetic material that combines the durability of polyester with the cushioning properties of foam. This innovative material is manufactured through a specialized process where polyester fibers are bonded together to create a resilient, lightweight structure. The resulting foam exhibits exceptional characteristics, including superior moisture resistance, excellent thermal insulation, and remarkable dimensional stability. The material's cellular structure allows for effective air circulation while maintaining its shape and supporting various load requirements. Polyester foam finds extensive applications across multiple industries, from furniture and bedding to automotive and packaging solutions. Its unique composition makes it particularly effective in environments where moisture resistance is crucial, as it doesn't retain water like traditional foam materials. The material's inherent properties also make it resistant to mold, mildew, and bacterial growth, ensuring long-term durability and hygiene. In technical applications, polyester foam serves as an excellent acoustic and thermal insulator, making it ideal for construction and industrial uses. The material's consistent quality and performance characteristics have made it a preferred choice for manufacturers seeking reliable, long-lasting foam solutions.