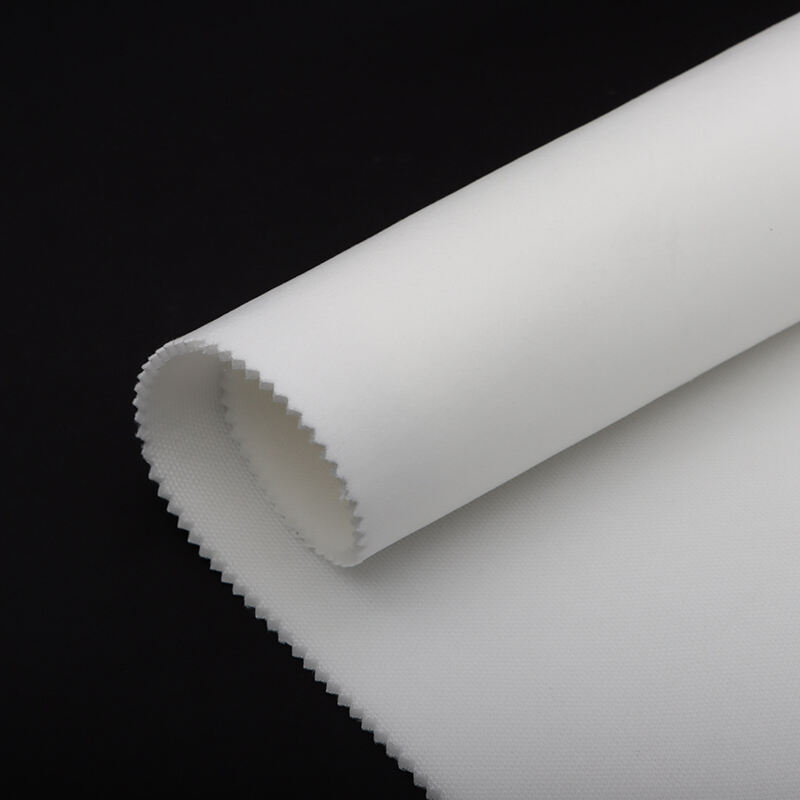

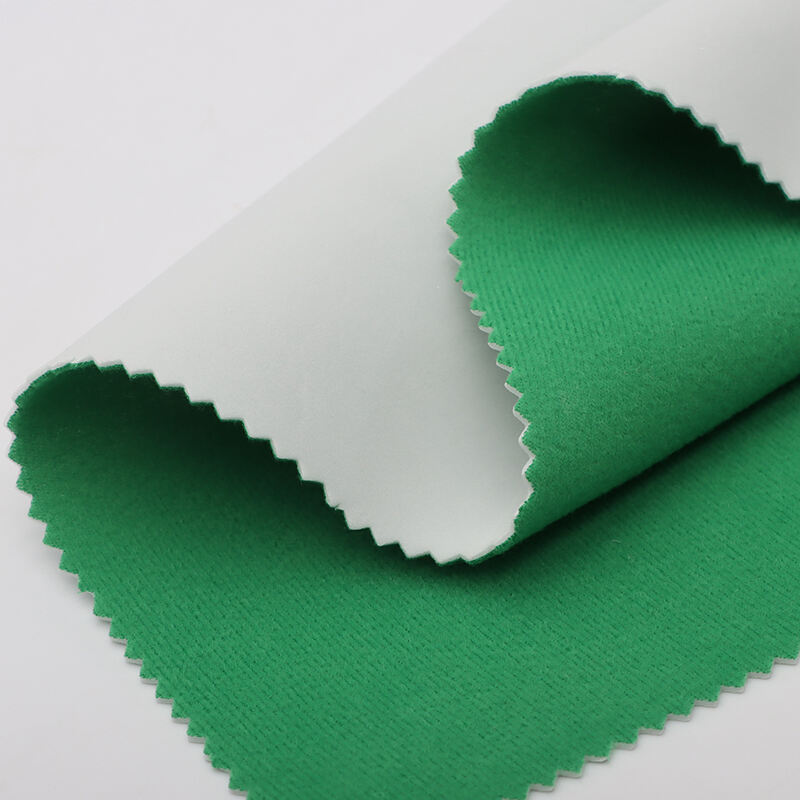

poly laminated foam fabric

Poly laminated foam fabric is an innovative composite material that combines the durability of polymer lamination with the comfort and insulation properties of foam, enhanced by a fabric backing. This advanced material consists of three distinct layers: a protective polymer coating, a foam core, and a fabric substrate, all bonded together through a sophisticated lamination process. The polymer layer provides excellent moisture resistance and durability, while the foam core offers superior cushioning and thermal insulation. The fabric backing adds structural integrity and a comfortable touch point for end users. This versatile material has revolutionized various industries, from automotive interiors to medical equipment padding and protective gear. The unique construction allows for exceptional sound dampening properties while maintaining flexibility and resilience under various environmental conditions. Its closed-cell structure prevents moisture absorption, making it ideal for applications requiring waterproof properties. The material can be manufactured in different thicknesses and densities to meet specific requirements, and its surface can be textured or smooth depending on the intended use. Furthermore, poly laminated foam fabric exhibits outstanding tear resistance and dimensional stability, ensuring long-term performance in demanding applications.