polyester foam fabric supplier

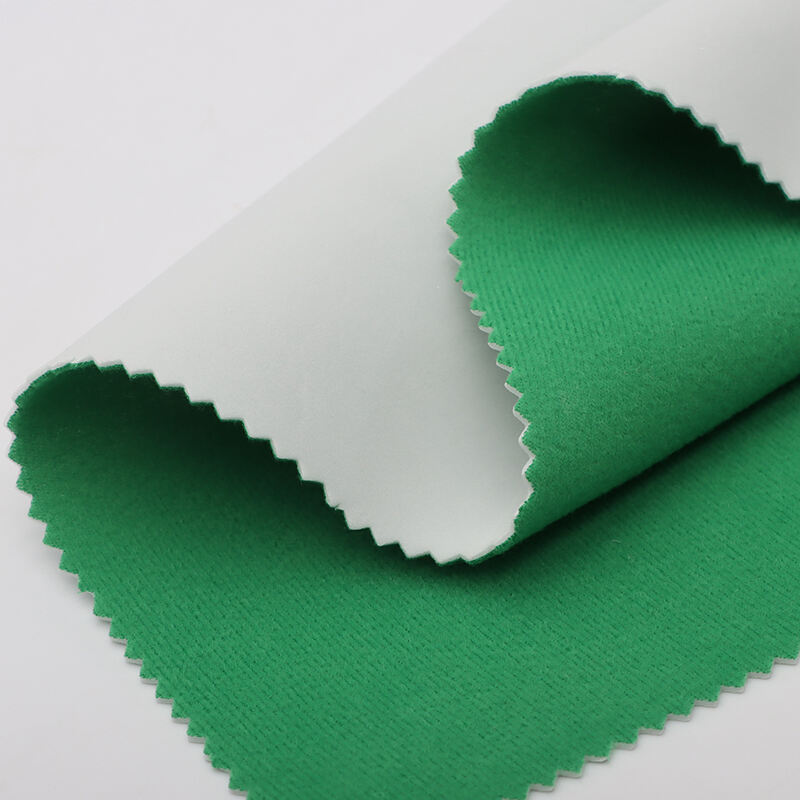

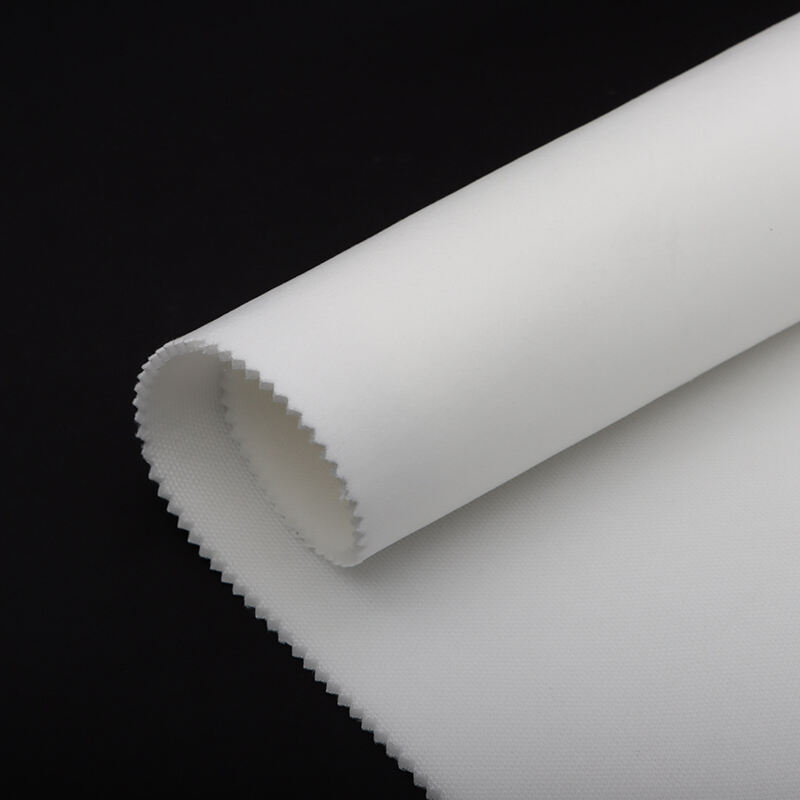

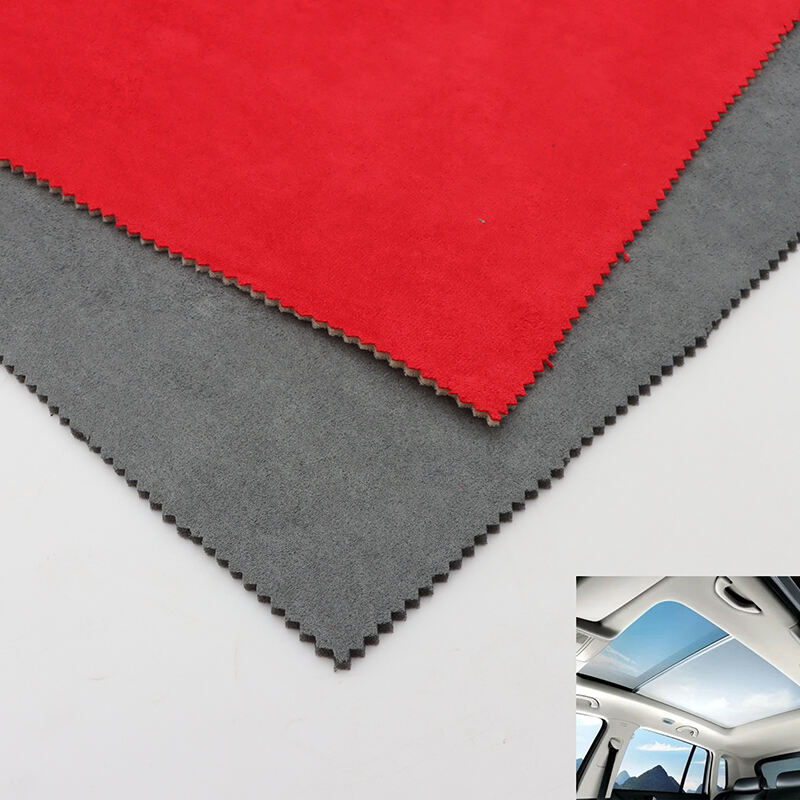

A polyester foam fabric supplier stands as a crucial partner in the textile and manufacturing industries, offering specialized materials that combine the durability of polyester with the comfort and versatility of foam construction. These suppliers provide comprehensive solutions for various applications, leveraging advanced manufacturing processes to create high-quality foam-backed fabrics. The materials they produce feature innovative layering techniques that bond polyester fabrics with various foam densities, resulting in products that excel in both functionality and comfort. Their manufacturing facilities typically employ state-of-the-art equipment capable of handling large-scale production while maintaining consistent quality standards. The supplier's expertise extends beyond mere production, encompassing material selection, custom formulation, and technical support to ensure optimal product performance. They maintain strict quality control measures throughout the production process, from raw material sourcing to final product testing, ensuring that each batch meets specific industrial standards and customer requirements. The supplier's product range typically includes various foam thicknesses, densities, and polyester fabric combinations, allowing for customization based on specific application needs. Their technical teams work closely with clients to develop solutions that address particular challenges in areas such as automotive interiors, furniture manufacturing, sports equipment, and protective gear.