oem polyester foam fabric

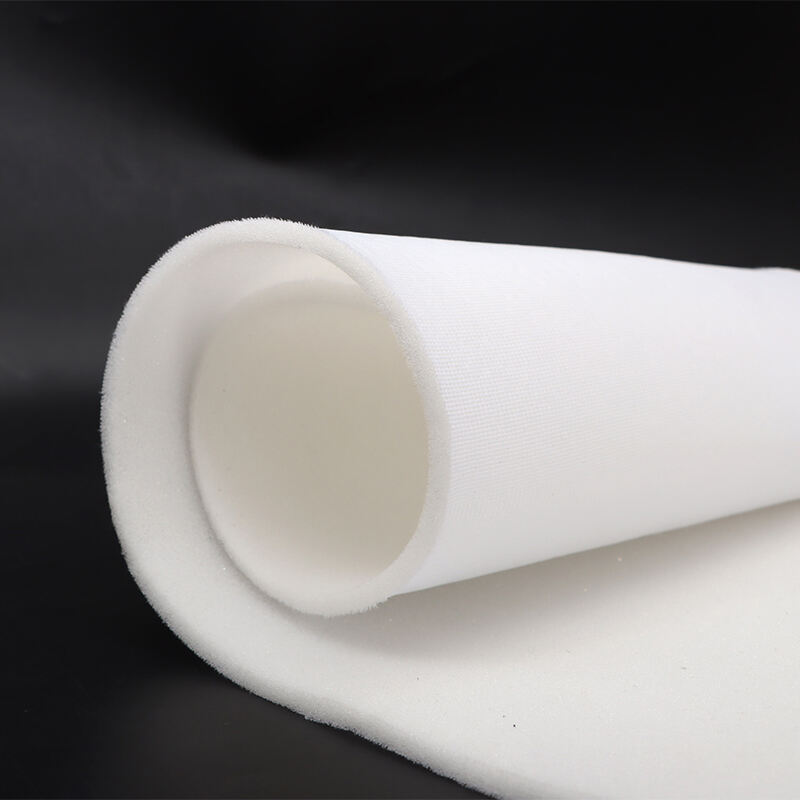

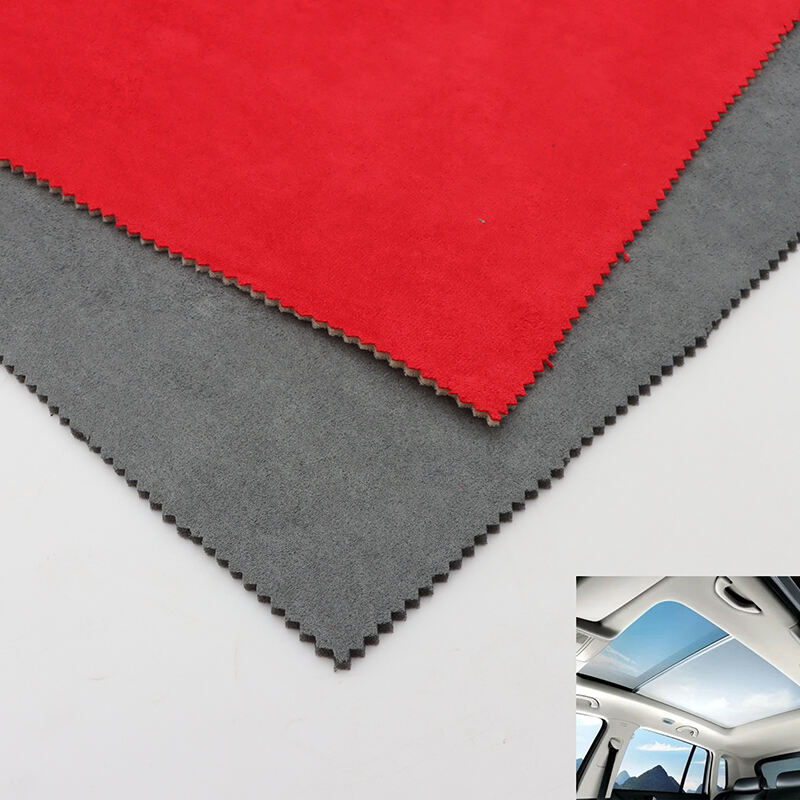

OEM polyester foam fabric represents a revolutionary composite material that combines the durability of polyester fibers with innovative foam technology. This versatile material consists of a polyester fabric base integrated with specialized foam components, creating a unique textile solution that offers both structural integrity and comfort. The manufacturing process involves carefully bonding foam elements to high-quality polyester fabric using advanced lamination techniques, resulting in a product that maintains its shape and performance characteristics over extended periods. The fabric's structure features microscopic air pockets within the foam layer, contributing to its exceptional insulation properties and moisture-wicking capabilities. This engineered textile solution finds extensive applications across various industries, from automotive interiors and furniture upholstery to sportswear and medical textiles. The material's ability to provide cushioning, thermal regulation, and moisture management makes it particularly valuable in applications requiring both comfort and functionality. Its customizable nature allows manufacturers to adjust thickness, density, and surface texture according to specific requirements, making it an ideal choice for diverse product applications.