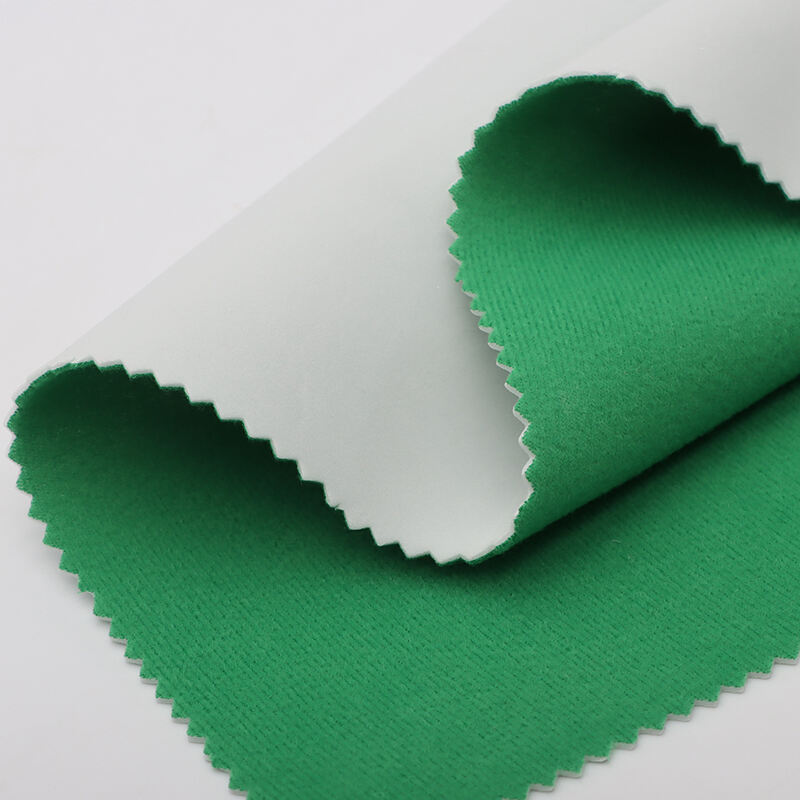

polyester foam fabric manufacturer

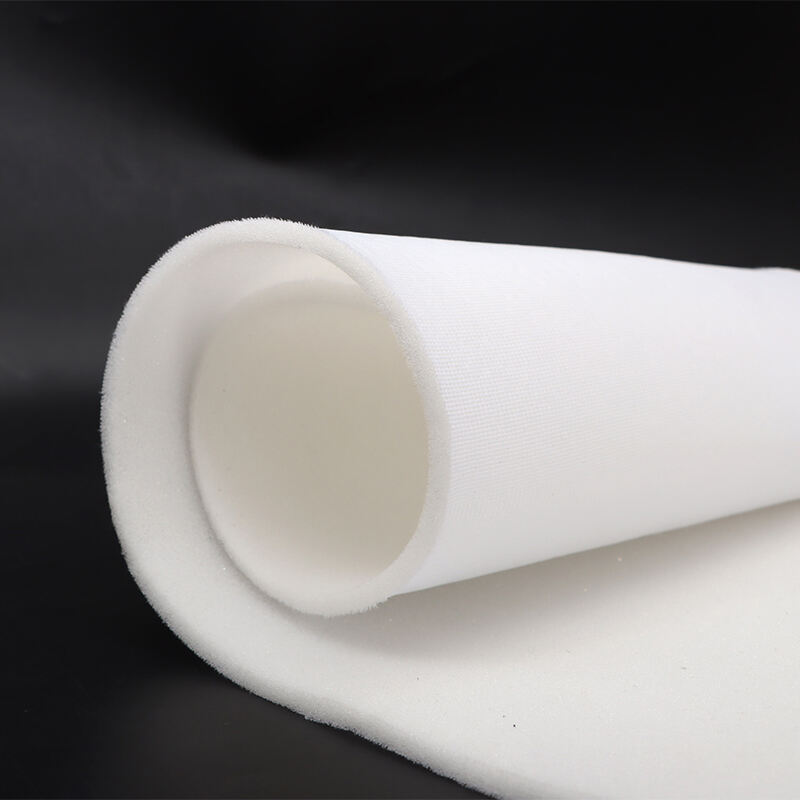

A polyester foam fabric manufacturer represents a pivotal force in the textile industry, specializing in the production of innovative composite materials that combine the durability of polyester with the comfort of foam technology. These manufacturers employ state-of-the-art production facilities equipped with advanced machinery capable of creating precise foam formulations and consistent fabric quality. The manufacturing process involves sophisticated techniques such as thermal bonding, needle punching, and chemical treatment to produce materials that meet specific performance requirements. These facilities typically operate with multiple production lines dedicated to different product specifications, from lightweight comfort foams to high-density technical materials. The manufacturer's capability extends to customizing foam density, thickness, and surface treatments according to client specifications, ensuring versatility in application across various industries. Quality control systems implemented throughout the production process maintain strict adherence to international standards, while research and development teams continuously work on improving material properties and developing new applications. The manufacturer's expertise encompasses not only the production of standard polyester foam fabrics but also specialized variants with enhanced characteristics such as moisture-wicking capabilities, antimicrobial properties, and flame-retardant features.