What Is Industry Foam Fabric and How Is It Used?

Defining Industry Foam Fabric

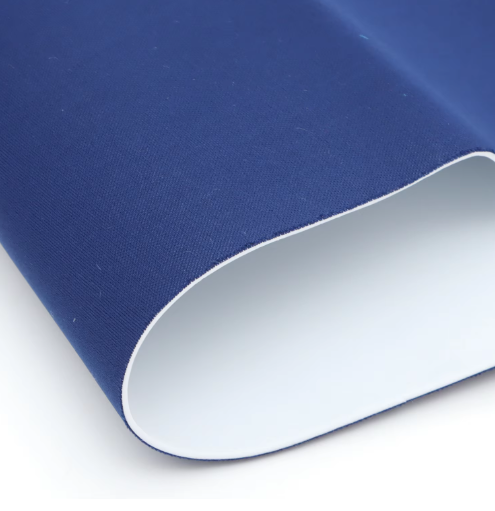

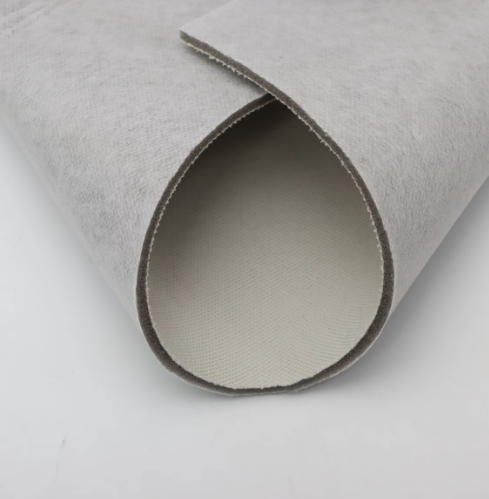

What we call industry foam fabric is basically a combination of soft foam layers stuck together with different types of textiles, creating something that's tough enough for serious work but still adaptable to specific needs. Manufacturers put these layered materials to work in all sorts of places - think car seats, building insulation, even hospital equipment and electronic device padding. When foam meets fabric, it gives products both strength where they need it and looks that matter too. That's why so many companies find these materials useful not just for what they do, but also how they look on store shelves or installed in finished products.

Industrial foam fabrics are typically constructed using polyurethane (PU), polyethylene (PE), or ethylene-vinyl acetate (EVA) foams laminated with woven or nonwoven fabrics. The lamination process can involve flame bonding, adhesive lamination, or thermal pressing, each chosen based on the desired durability, breathability, and environmental resistance.

Characteristics and Performance Criteria

One of the main reasons industry foam fabric is widely used is due to its balance of properties. These materials are designed to provide cushioning, impact resistance, acoustic dampening, and thermal insulation. Furthermore, surface fabrics can be selected for their abrasion resistance, chemical stability, or even aesthetic appeal.

Depending on the intended use, the density and thickness of the foam can be customized to meet different performance requirements. For example, denser foam may be used in construction or automotive applications to improve mechanical stability, while softer foam variants may be ideal for medical supports or protective clothing.

Key Applications Across Industries

Automotive and Transportation

In the automotive industry, industry foam fabric is commonly found in headliners, door panels, seating systems, and sound-dampening areas. These fabrics offer enhanced comfort, noise insulation, and resistance to wear over time. Additionally, they can be paired with decorative fabrics that align with vehicle interior themes.

In public transport systems such as buses, trains, and aircraft, flame-retardant foam fabrics are used to meet strict safety regulations. These materials also help reduce vibrations and cabin noise, enhancing the passenger experience.

Construction and Architecture

Foam fabric has become essential for insulation, sealing gaps, and creating protective barriers throughout construction projects. Builders commonly install it in wall cavities, line HVAC ducts with it, and lay it beneath flooring materials as well. What makes this material so valuable is its ability to both cushion surfaces and trap heat effectively. These properties not only keep buildings at comfortable temperatures but also significantly cut down on sound traveling through walls and between different levels of a structure.

Additionally, waterproof and fire-retardant variants are preferred for buildings that require high levels of protection against environmental stress. Foam-backed fabrics used in wall treatments or acoustic panels improve indoor air quality and living comfort in commercial and residential buildings.

Healthcare and Medical Equipment

Foam fabric materials are used in the manufacturing of orthopedic braces, hospital mattresses, surgical table padding, and patient mobility aids. Medical-grade foams must meet stringent biocompatibility and hygiene standards, while the laminated fabric surfaces are designed for easy cleaning and sterilization.

The flexibility and adaptability of foam fabrics allow them to be custom-cut or molded to specific shapes, offering ergonomic support and reducing pressure points. This is particularly important for patients with mobility issues or long-term hospital stays.

Enhancing Functionality with Material Engineering

Surface Fabric Selection

The performance of industry foam fabric is significantly influenced by the choice of surface textile. For heavy-duty industrial applications, high-tenacity polyester or nylon fabrics are commonly used due to their durability and chemical resistance. For softer, more tactile applications, cotton or microfiber may be used to enhance comfort.

In high-tech environments, antistatic or conductive fabrics can be laminated onto foam to manage electrostatic discharge. Such materials are critical in the electronics industry where sensitive components require ESD protection during manufacturing or transport.

Specialized Foam Properties

Manufacturers often tailor foam compositions to provide additional features. Open-cell foams offer breathability and air permeability, suitable for applications where ventilation is necessary. Closed-cell foams are preferred for moisture resistance and impact protection.

Flame-retardant additives, antimicrobial agents, and UV stabilizers can also be incorporated into foam materials to meet specific environmental or safety demands. These engineered modifications expand the usability of foam fabrics in extreme or regulated conditions.

Manufacturing and Quality Considerations

Lamination Techniques

Choosing the appropriate lamination method is crucial in achieving the desired bond strength and performance. Flame lamination is commonly used for PU foams, creating strong adhesion without added chemicals. Adhesive lamination is more versatile and suitable for heat-sensitive fabrics, though it may introduce VOC emissions if not managed properly.

Thermal pressing offers a balance between eco-friendliness and performance and is often used when processing EVA or PE foams. The consistency of lamination ensures product quality and reduces the risk of delamination under stress.

Testing and Standards Compliance

To ensure performance and safety, industry foam fabrics undergo rigorous testing for mechanical properties, flammability, tensile strength, and environmental stability. Compliance with industry standards such as ISO, ASTM, or regional certifications like REACH and RoHS is essential, particularly in sensitive sectors such as medical and automotive manufacturing.

Manufacturers often work with OEMs to tailor foam fabric products that meet precise design tolerances and lifecycle expectations. Customization capabilities, from thickness to finish, provide additional value to industrial clients seeking high-performance materials.

Sustainability and Future Trends

Eco-Conscious Innovations

With growing emphasis on sustainability, the foam fabric industry is exploring biodegradable foams, recycled textiles, and water-based adhesives to reduce environmental impact. Manufacturers are adopting closed-loop recycling systems and investing in green chemistry to replace hazardous substances.

In industries like packaging or disposable medical supplies, the development of compostable foam laminates is a growing trend. These efforts support corporate ESG goals and comply with emerging regulatory frameworks worldwide.

Smart and Functional Materials

The integration of sensors, heating elements, or reactive textiles into foam fabric is paving the way for next-generation industrial products. Smart foam materials can monitor pressure, temperature, or strain, making them valuable in medical diagnostics, wearable technology, or structural health monitoring.

Foam fabrics that change color or texture in response to environmental stimuli are also being developed for advanced packaging and user-interface applications. These innovations are expected to open new markets and drive further investment in material science.

FAQ

What is industry foam fabric made from?

It is made by laminating foam materials like PU, PE, or EVA with fabrics such as polyester, nylon, or cotton using flame, adhesive, or thermal lamination methods.

In what industries is foam fabric commonly used?

It is widely used in automotive, construction, medical, electronics, and packaging industries for insulation, cushioning, protection, and aesthetic purposes.

Can foam fabric be customized for specific applications?

Yes, foam density, thickness, fabric type, and added properties like flame resistance or antimicrobial agents can all be tailored to meet specific requirements.

Are there eco-friendly options for industrial foam fabrics?

Yes, sustainable options using recycled materials, biodegradable foams, and low-emission adhesives are increasingly available in the market.