Why 3mm Polyester Foam Fabric Excels in Lightweight Padding Applications

Superior Lightweight Structure

Three millimeter polyester foam fabric has become pretty popular because it strikes just the right balance between being light and still doing what needs to be done. What makes this material stand out is how the thin layer of foam gives enough cushioning without making things feel heavy or bulky. That's why manufacturers love using it whenever they need to cut down on weight but still want some level of comfort or protection. Take a look around and you'll see this stuff showing up everywhere from clothing to car interiors and even electronic devices where every gram counts.

In garment manufacturing, for example, 3mm polyester foam inserts are commonly used in shoulder pads or protective gear, offering structure and shock absorption without burdening the wearer. Its lightweight nature also contributes to lower shipping costs and easier handling during mass production.

Effective Cushioning and Support

Despite its minimal thickness, 3mm polyester foam fabric delivers impressive support and shock absorption. It provides a comfortable buffer that protects sensitive surfaces and enhances the ergonomic qualities of wearable or transportable items. This makes it suitable for linings in bags, helmets, and sportswear.

The foamâs consistent cell structure ensures uniform compression and recovery, making it reliable over time. It offers a resilient padding layer that returns to its original shape after use, contributing to product longevity and performance stability.

Functional Versatility Across Industries

Adaptability in Design

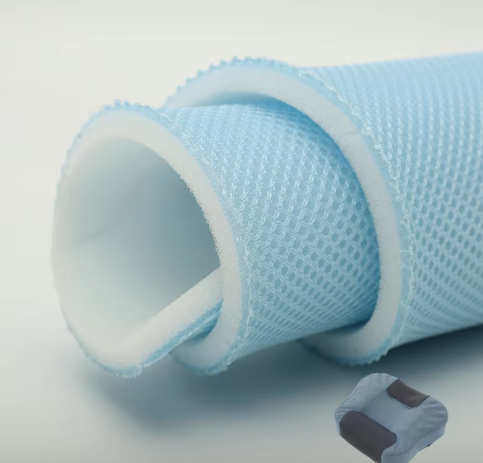

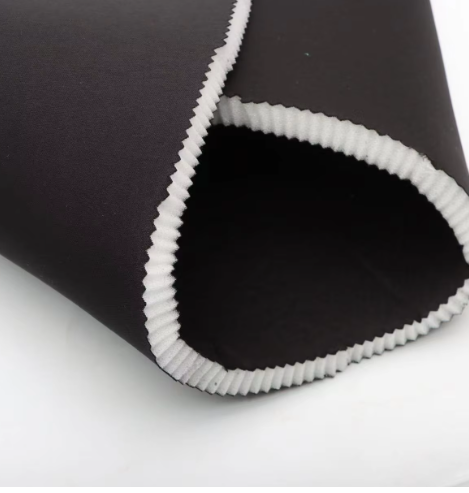

3mm polyester foam fabric is compatible with a range of outer fabrics and bonding methods, allowing it to integrate seamlessly into different product designs. Its flexibility enables designers to contour and shape products as needed, which is particularly useful in creating ergonomic or aesthetically tailored components.

The material's ease of lamination with textiles such as nylon, cotton, or mesh supports a wide variety of end uses. Whether for fashion, luggage, or seating, its adaptability supports design freedom without compromising structural integrity.

Cost-Effective Solution

Manufacturers appreciate 3mm polyester foam fabric for its cost-efficiency. The material is affordable and readily available, which helps keep production costs in check. It also reduces waste due to its consistent thickness and easy-to-cut properties, enabling efficient material usage during fabrication.

In large-scale production environments, the use of pre-laminated 3mm foam sheets can accelerate assembly lines and minimize bonding errors. This practicality translates into savings both in time and resources.

Protective and Durability Benefits

Thermal and Moisture Resistance

Polyester foam exhibits natural resistance to moisture and mild temperature variations, making it suitable for environments where humidity or sweat exposure is common. When used in wearable items or accessories, it helps prevent moisture buildup and maintains user comfort.

Its thermal stability allows it to retain performance in both indoor and moderately challenging outdoor conditions. This makes it suitable for items like seat padding, gloves, or travel gear, where resilience under varied usage environments is required.

Long-Term Performance

Durability is a key attribute of 3mm polyester foam fabric. The foam retains its shape and protective characteristics even after repeated compression. It resists deformation, tearing, and surface breakdown, ensuring products maintain their functionality and appearance over time.

This long-lasting quality makes it a preferred choice for items that undergo frequent handling, such as cases, footwear, and industrial padding solutions. Even with prolonged use, the foam remains consistent in texture and support.

FAQ

What makes 3mm polyester foam ideal for lightweight padding?

Its thin yet resilient structure offers reliable cushioning without adding unnecessary weight, making it perfect for wearables and transportable items.

In which products is 3mm polyester foam fabric commonly used?

It is used in garments, bags, protective gear, automotive padding, and lightweight seating applications.

Can 3mm polyester foam be laminated with other materials?

Yes, it bonds well with various textiles like nylon, mesh, and cotton, enhancing versatility in design and function.

Is 3mm polyester foam fabric durable?

Absolutely. It maintains shape, resists moisture and temperature variation, and endures repeated use without degrading.