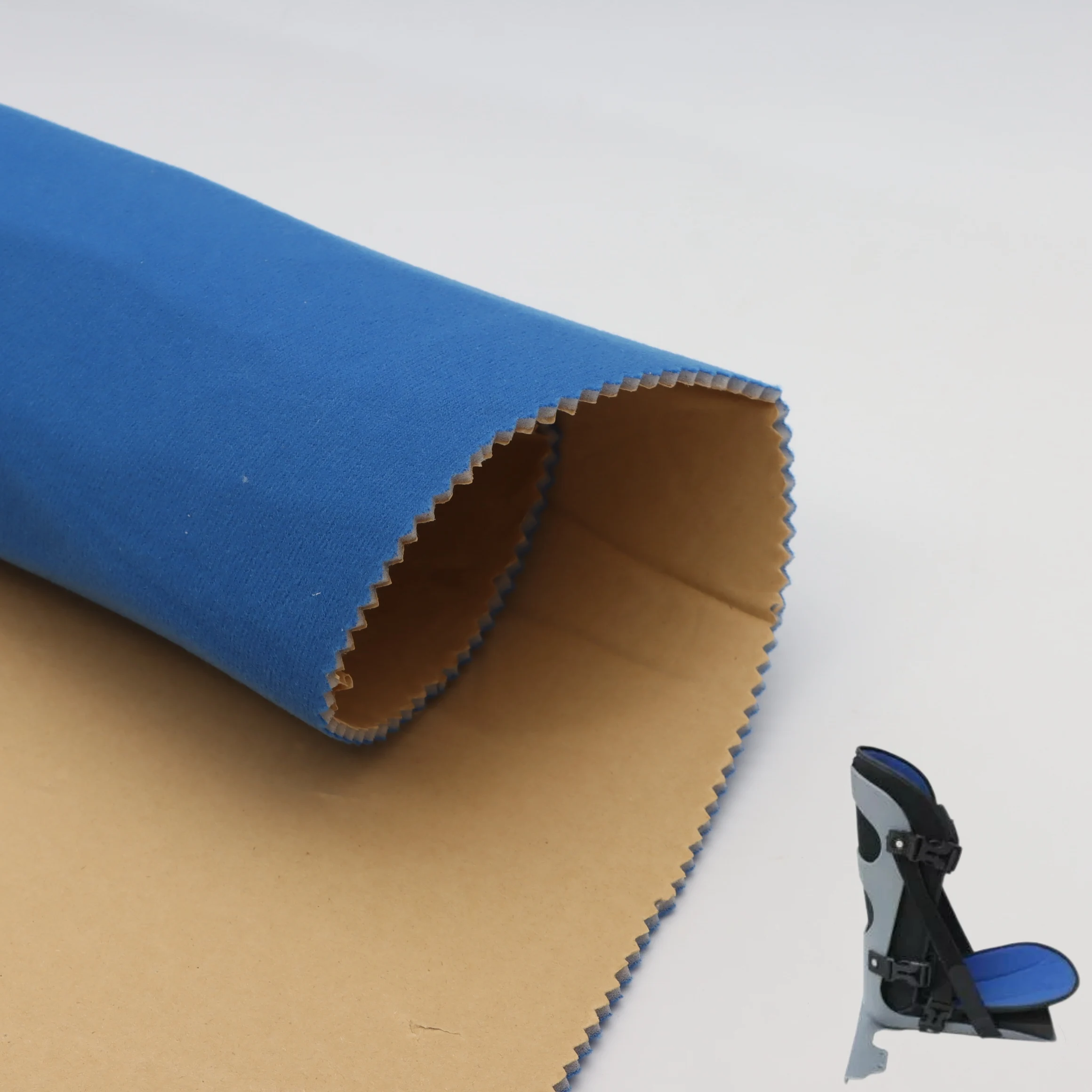

foam headliner material

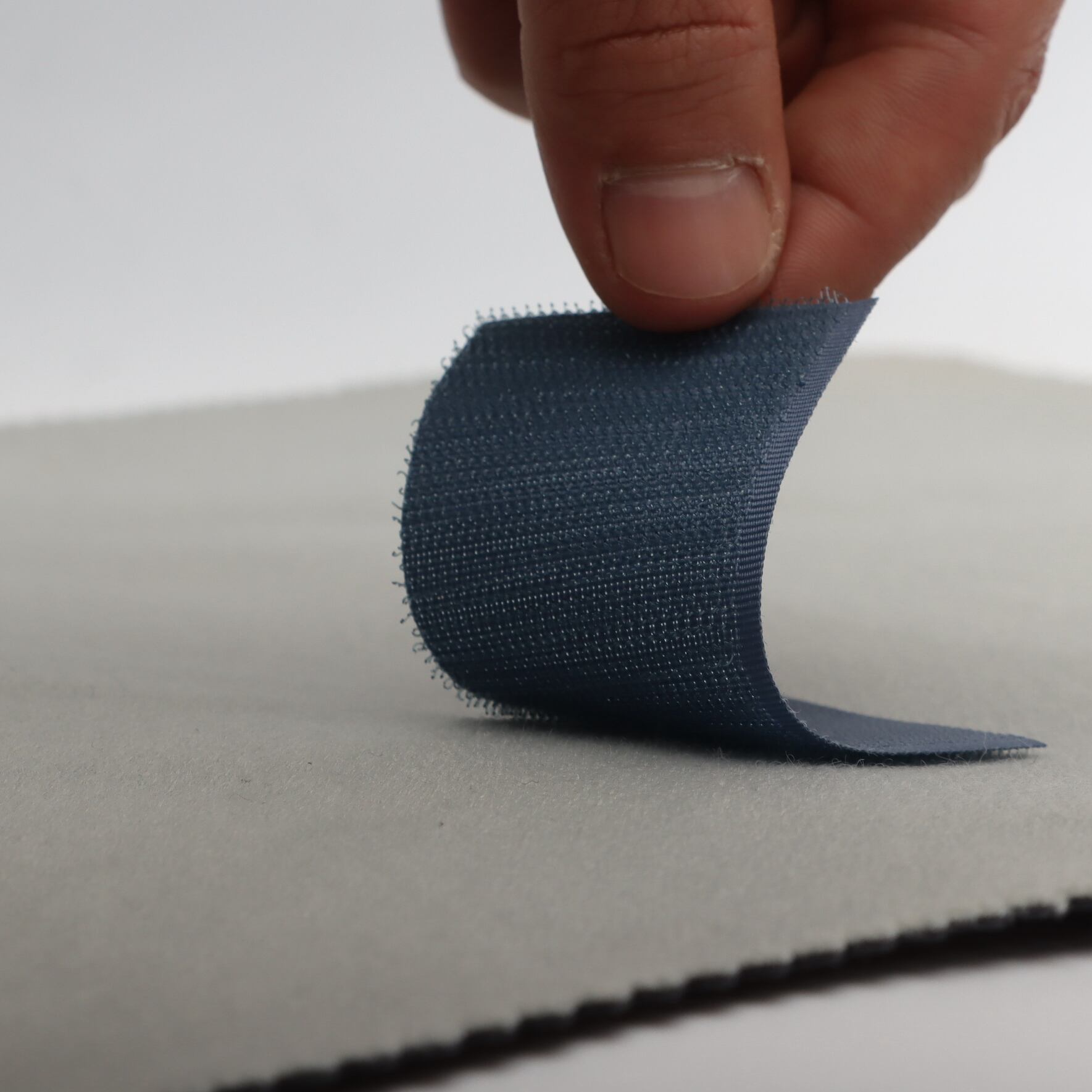

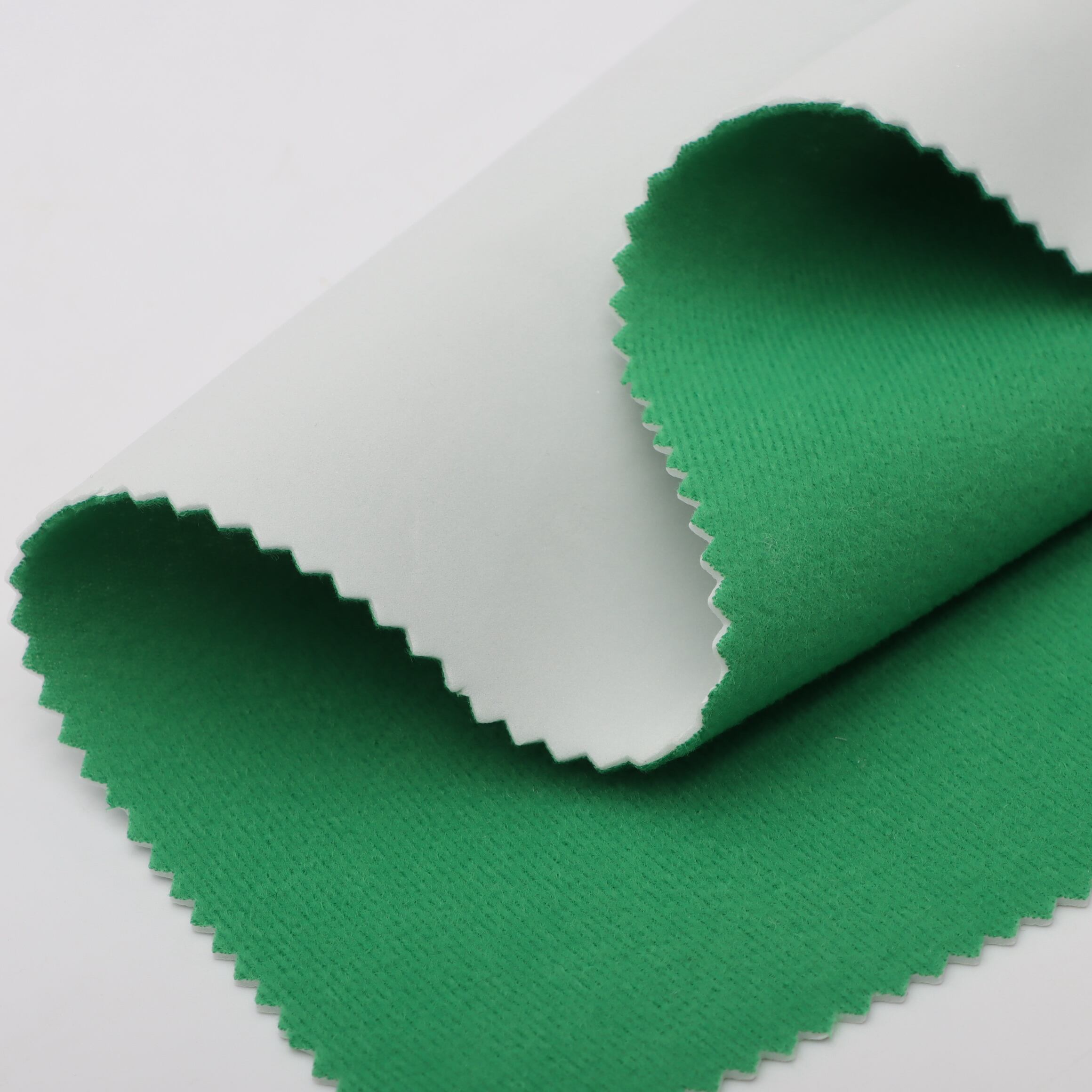

Foam headliner material represents a cutting-edge solution in automotive and construction industries, serving as a crucial component for ceiling applications. This versatile material consists of multiple layers, including a foam core that provides both structural integrity and sound absorption properties. The material's composition typically features a polyurethane or polyethylene foam base, laminated with decorative fabric or vinyl surfaces, creating a durable and aesthetically pleasing finish. The foam core's cellular structure effectively manages acoustic properties while maintaining lightweight characteristics, making it ideal for modern vehicle design and architectural applications. Engineers have developed this material to meet strict industry standards for safety, durability, and environmental compliance. The foam headliner material excels in thermal insulation, helping to regulate interior temperatures and reduce energy consumption. Its manufacturing process involves advanced bonding techniques that ensure long-term stability and resistance to delamination, even under varying temperature and humidity conditions. The material's flexibility allows for easy installation around curves and corners, while its structural properties provide excellent dimensional stability. Modern foam headliners also incorporate antimicrobial properties and UV resistance, extending their lifespan and maintaining appearance quality over time.