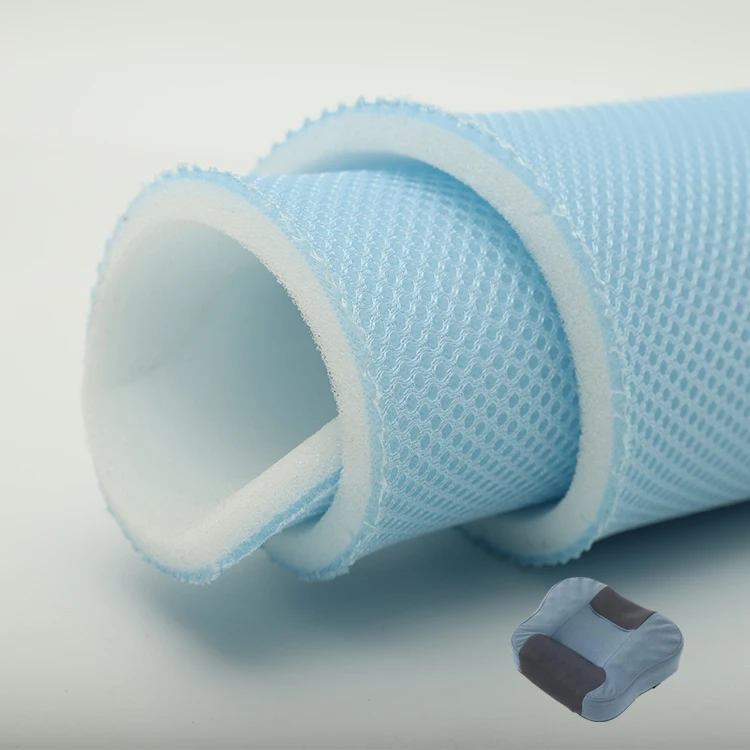

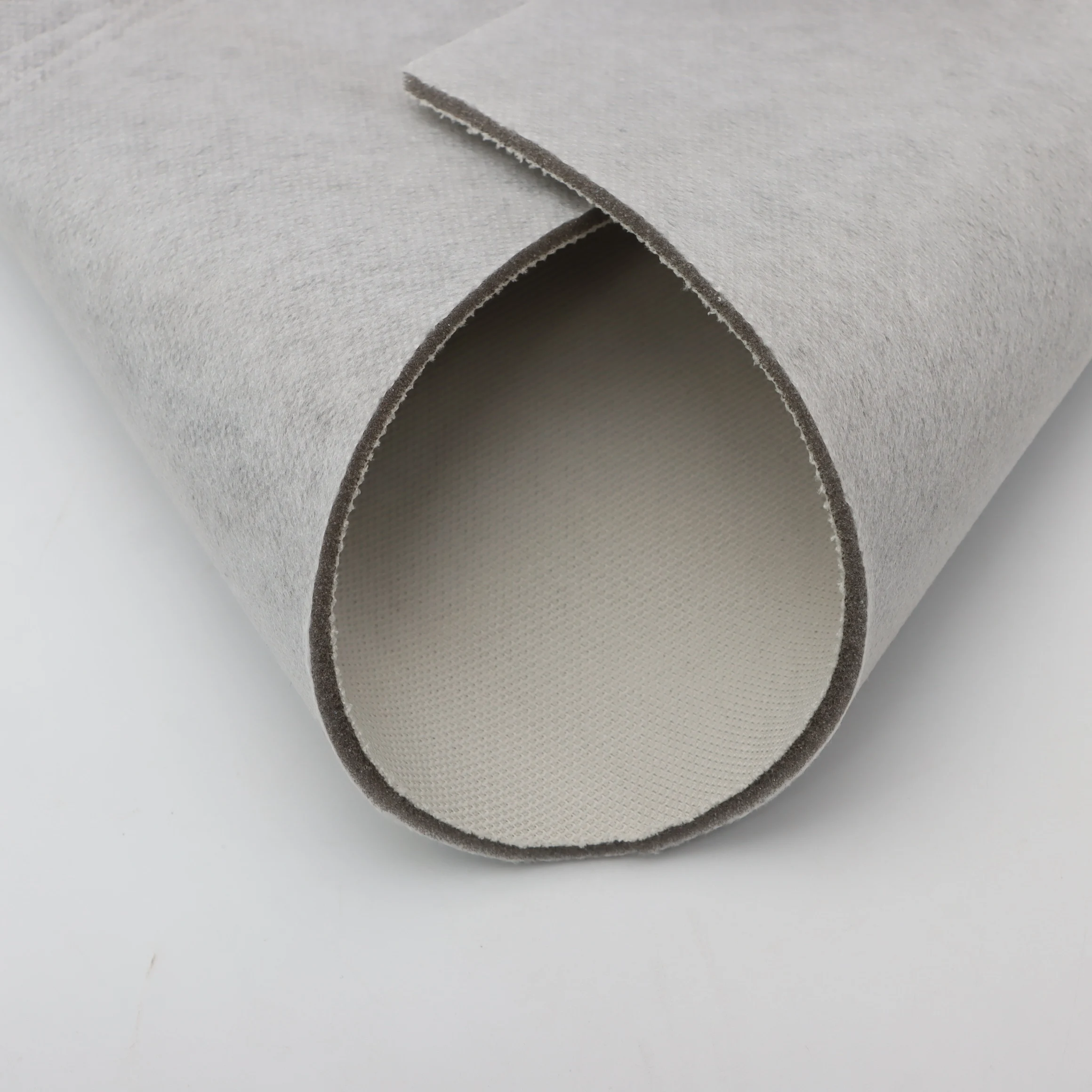

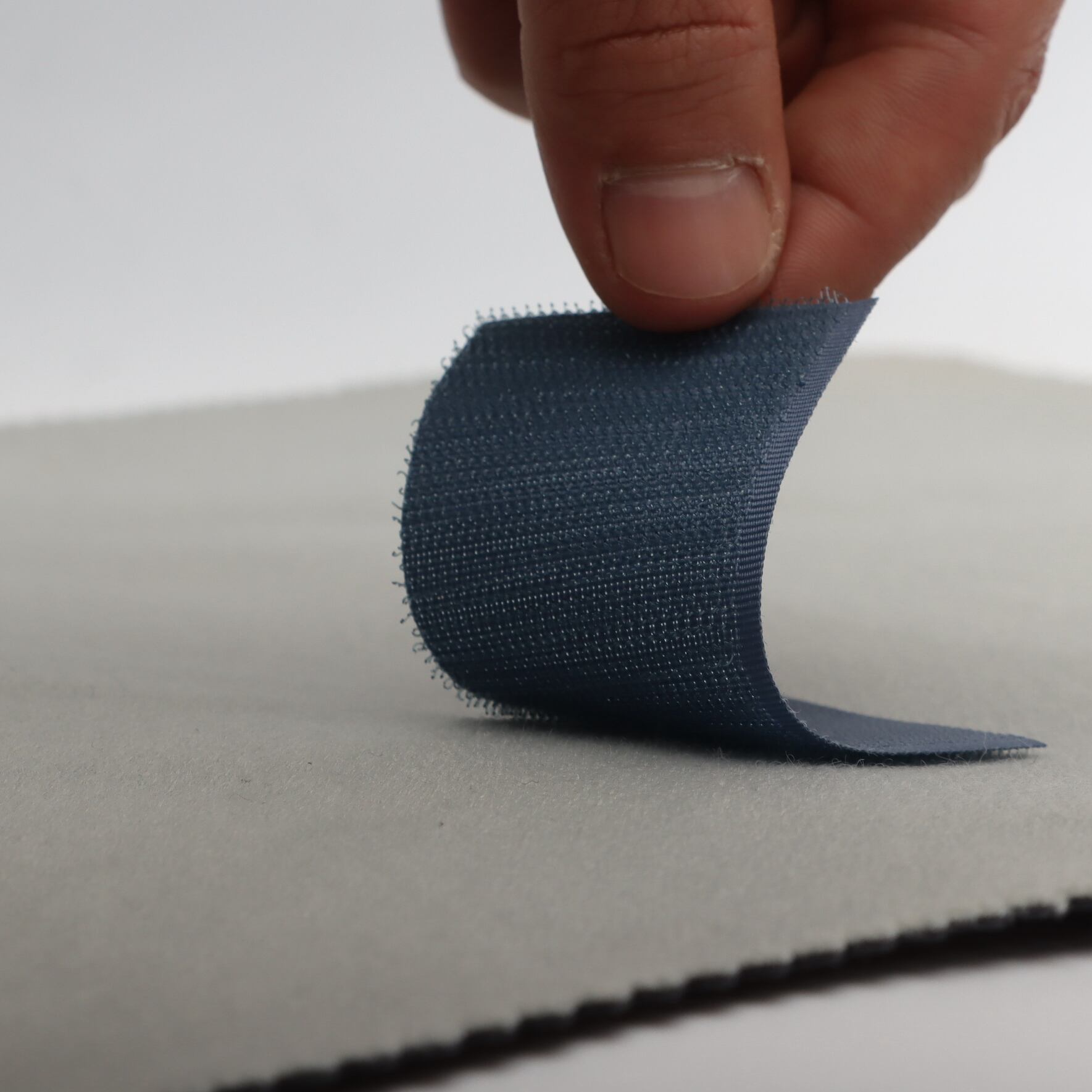

fabric foam backing

Fabric foam backing is an innovative textile enhancement technology that combines the comfort of traditional fabrics with the supportive properties of specialized foam materials. This composite structure consists of a layer of foam material permanently bonded to the reverse side of fabric surfaces, creating a dual-layer construction that significantly improves both functionality and comfort. The foam backing serves multiple purposes, including providing structural support, enhancing durability, and improving insulation properties. The technology employs various types of foam materials, such as polyurethane, latex, or memory foam, each selected based on specific application requirements. The manufacturing process involves precise bonding techniques that ensure the foam layer adheres uniformly to the fabric while maintaining flexibility and breathability. This technology finds widespread applications in furniture upholstery, automotive interiors, clothing, and home textiles. The foam backing can be customized in terms of thickness, density, and composition to meet specific performance requirements, making it highly versatile for different end uses. Modern fabric foam backing solutions also incorporate advanced features such as moisture-wicking properties, antimicrobial treatments, and enhanced durability characteristics.