auto upholstery foam backing

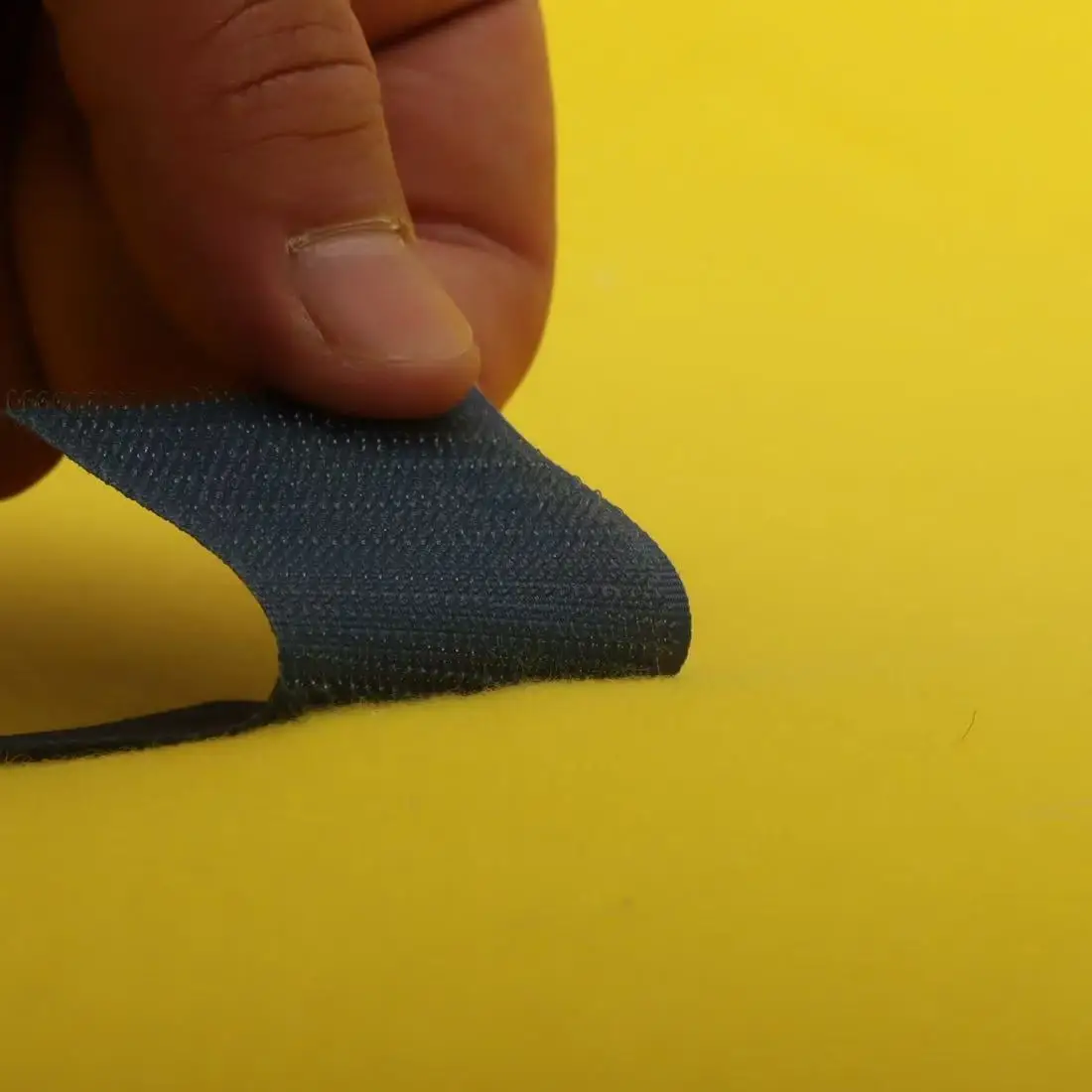

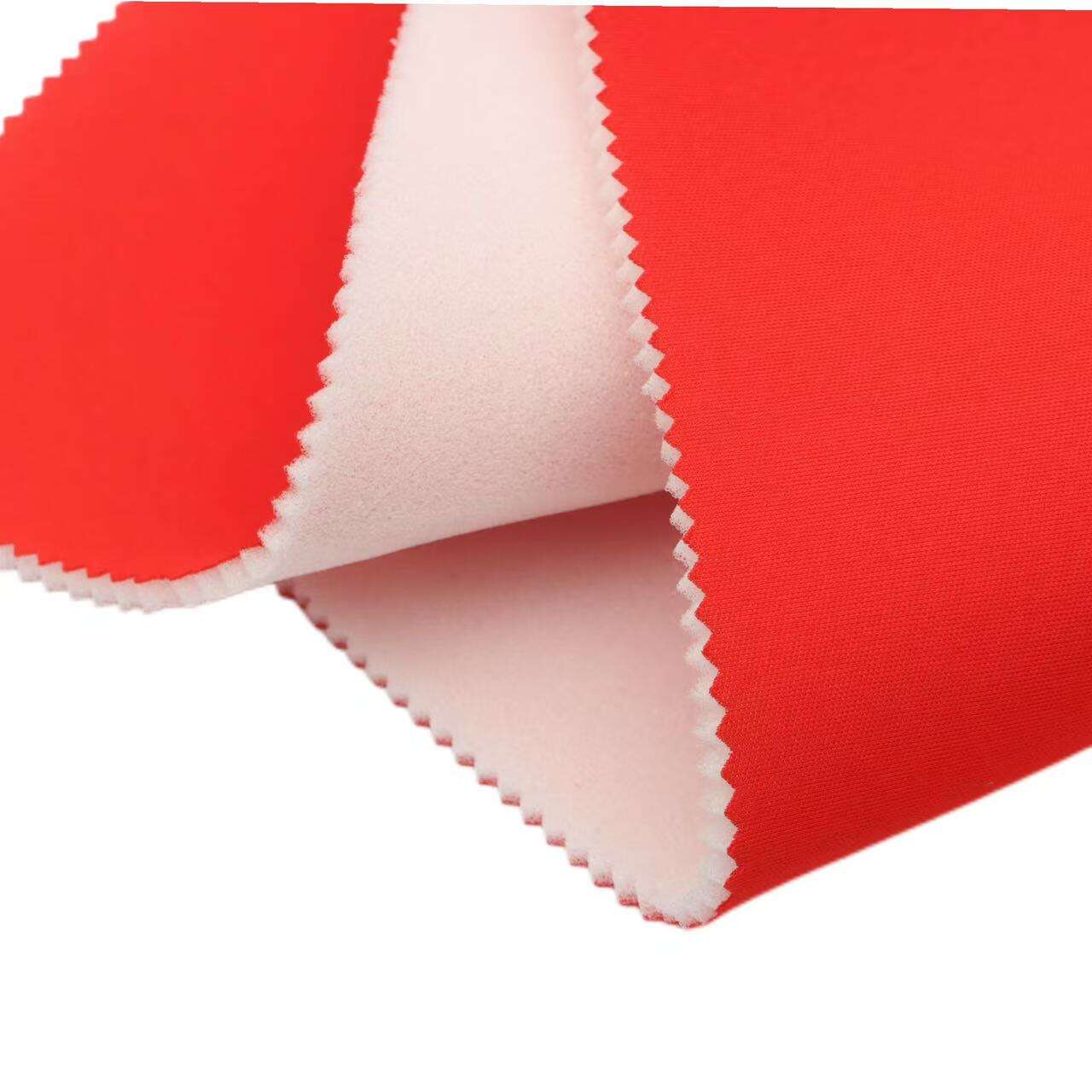

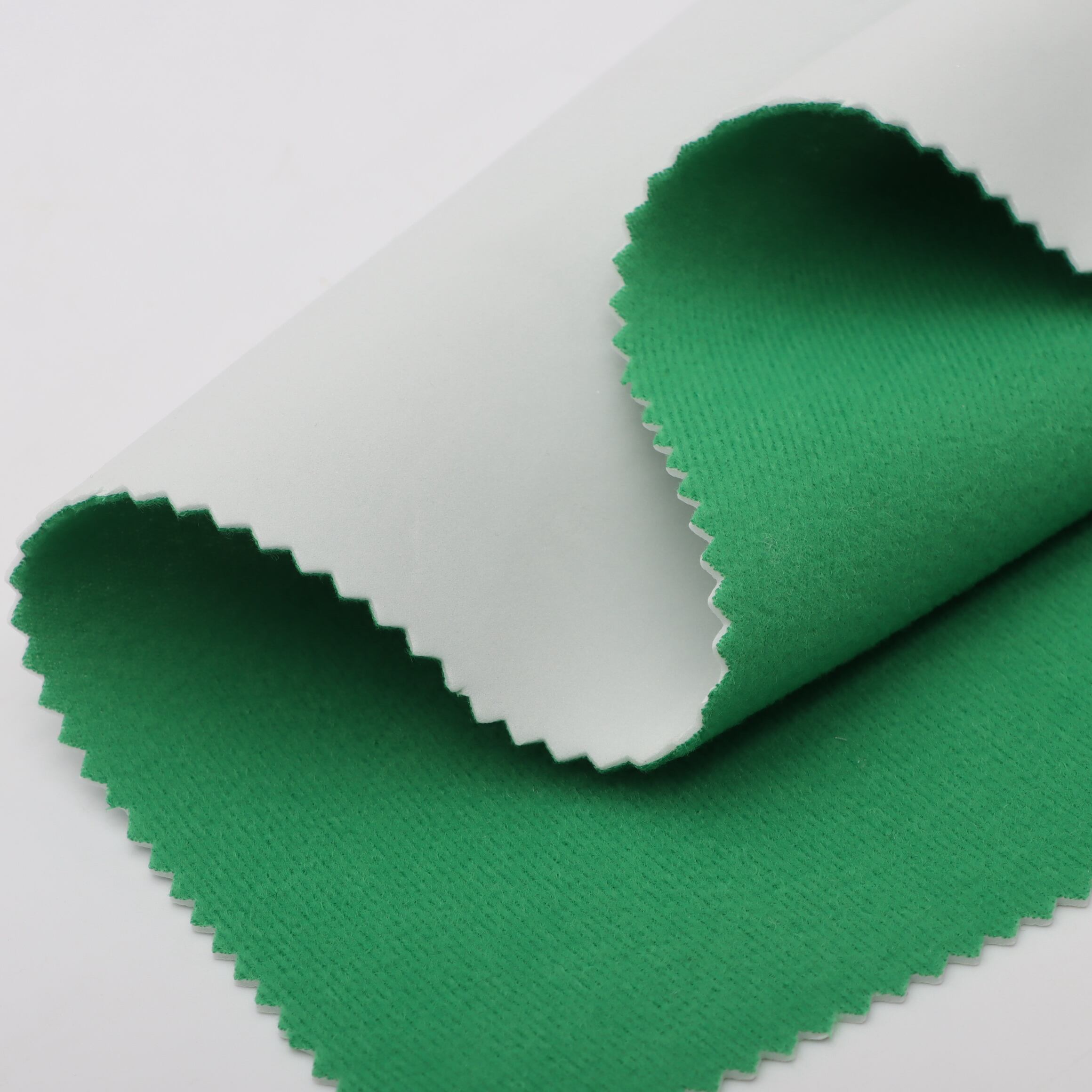

Auto upholstery foam backing is a crucial component in automotive interior design, serving as the foundation for comfortable and durable seating solutions. This specialized material consists of high-density polyurethane foam engineered specifically for automotive applications, providing essential support and cushioning for vehicle seating systems. The foam backing features a unique cellular structure that allows for optimal air circulation while maintaining its shape and resilience under various conditions. Modern manufacturing processes ensure consistent density distribution throughout the material, contributing to extended durability and performance. The foam backing is designed to work in harmony with various upholstery materials, creating a stable foundation that prevents sagging and maintains the intended seat profile over time. Its technical specifications typically include flame-retardant properties, resistance to UV degradation, and compatibility with different adhesive systems used in automotive assembly. The material's versatility allows it to be customized for different vehicle models and seating configurations, from basic economy cars to luxury vehicles requiring premium comfort levels.