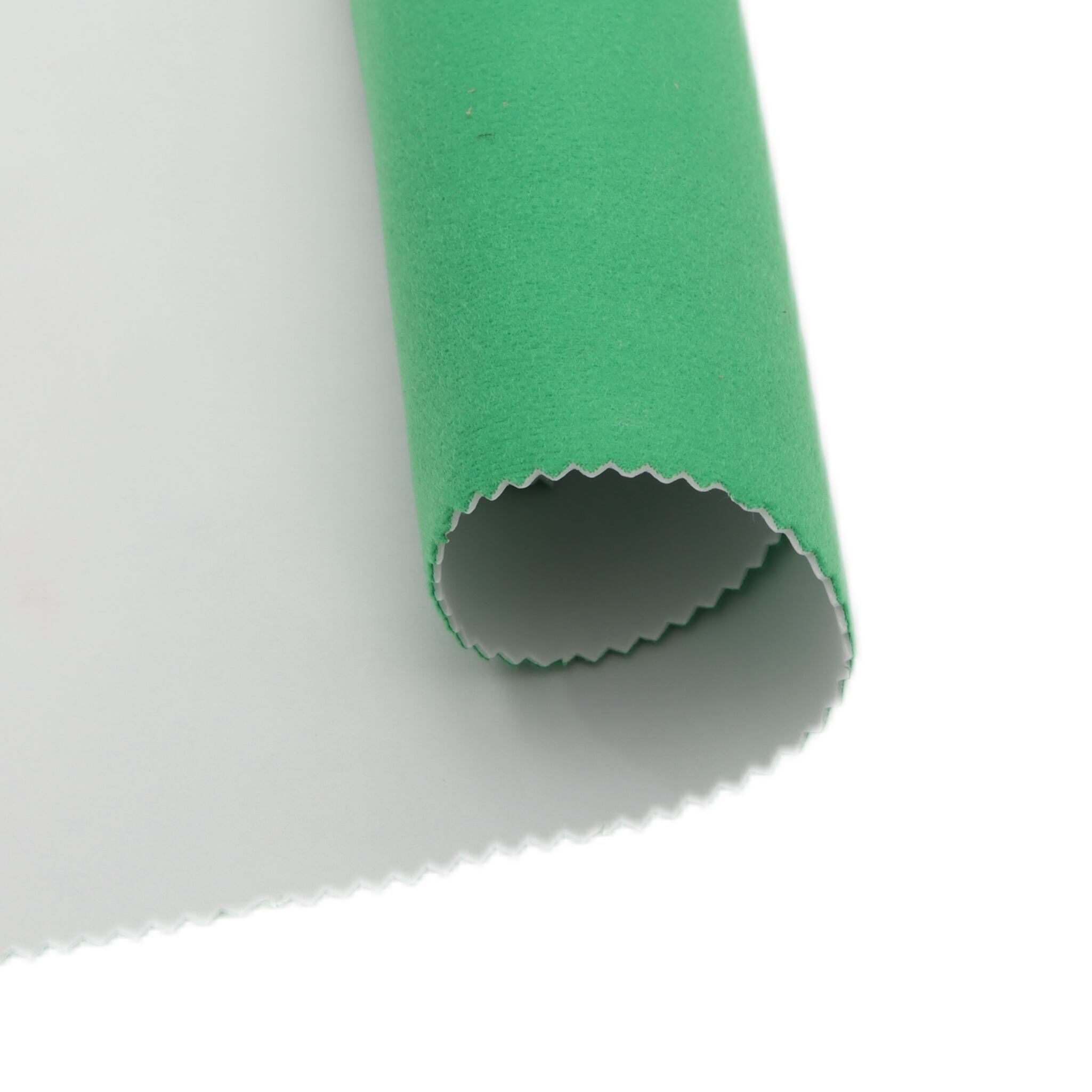

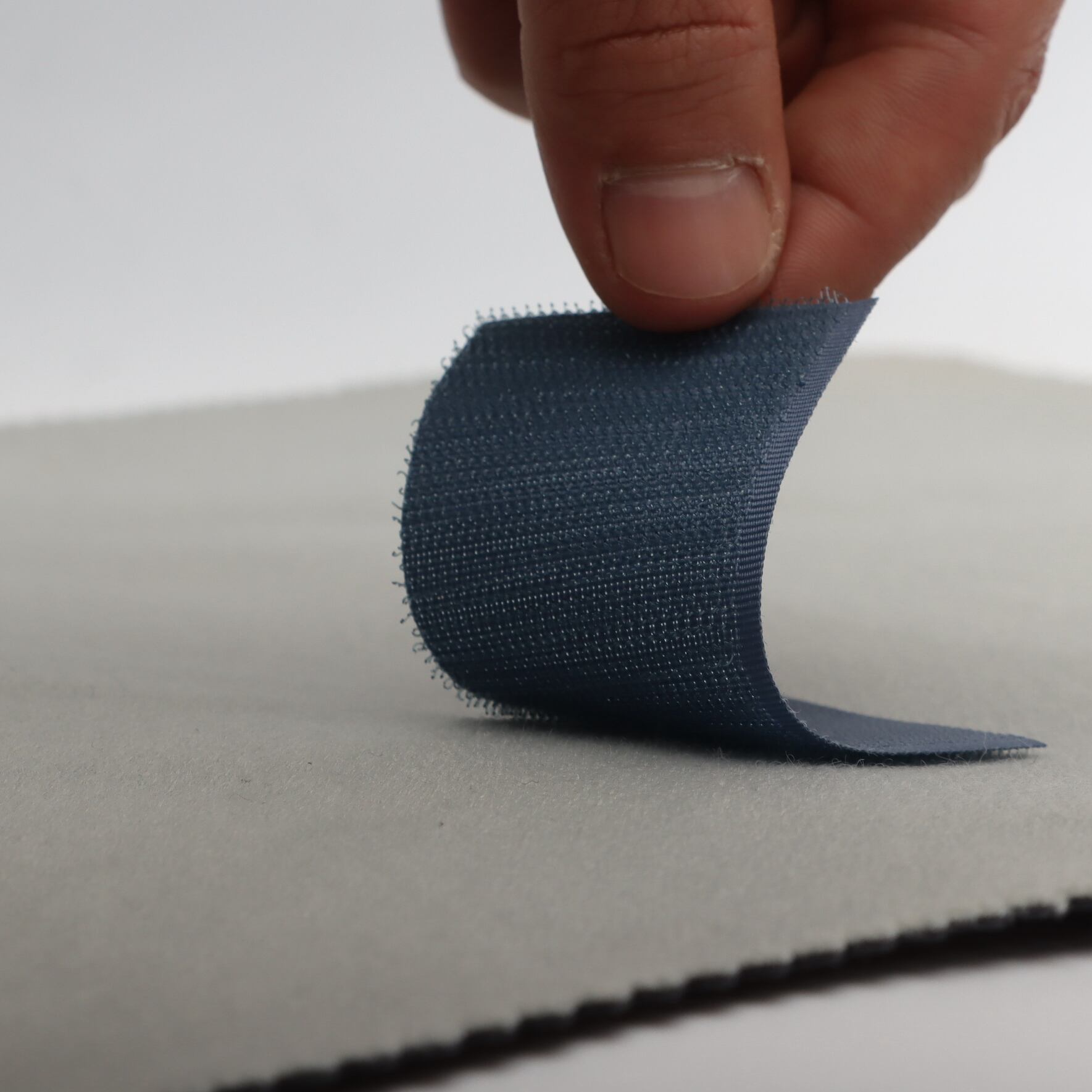

headliner fabric with foam backing

Headliner fabric with foam backing represents a sophisticated automotive interior solution that combines aesthetic appeal with functional performance. This specialized material consists of a decorative fabric layer permanently bonded to a foam substrate, creating a versatile composite that serves multiple purposes in vehicle interior applications. The foam backing provides essential structural support while enhancing acoustic properties and thermal insulation. The material's construction allows for excellent formability, enabling it to conform to various roof configurations and complex curves without compromising its appearance or performance. The fabric layer is engineered to resist UV radiation, preventing fading and deterioration over time, while also providing an attractive, uniform surface that contributes to the vehicle's interior aesthetics. Advanced manufacturing processes ensure consistent thickness and density across the material, guaranteeing reliable performance and durability. The foam backing is specifically formulated to maintain its structural integrity throughout temperature variations and environmental conditions typically encountered in automotive applications. This composite material also features integrated moisture resistance properties, helping to prevent the growth of mold and mildew while maintaining its dimensional stability throughout the vehicle's lifecycle.