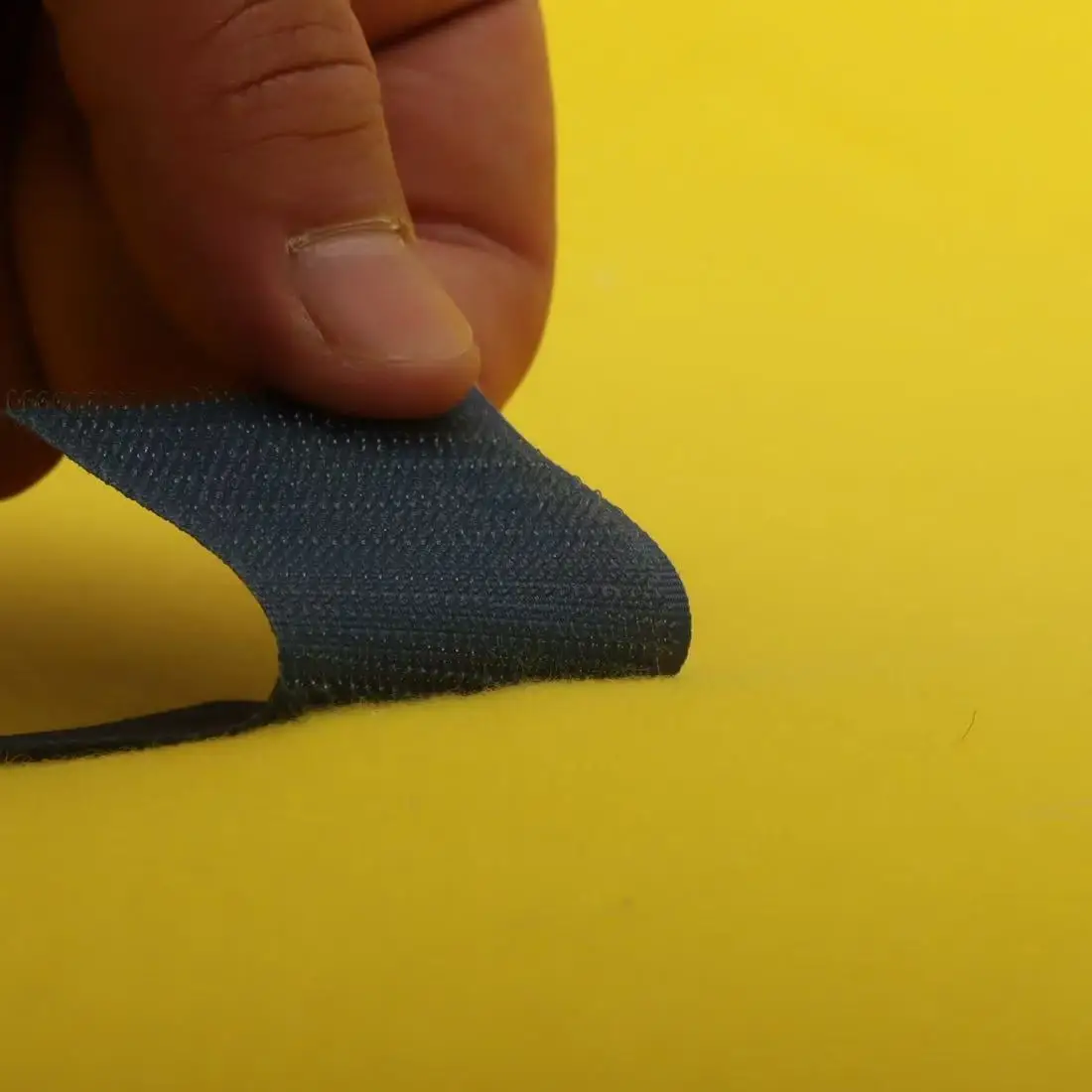

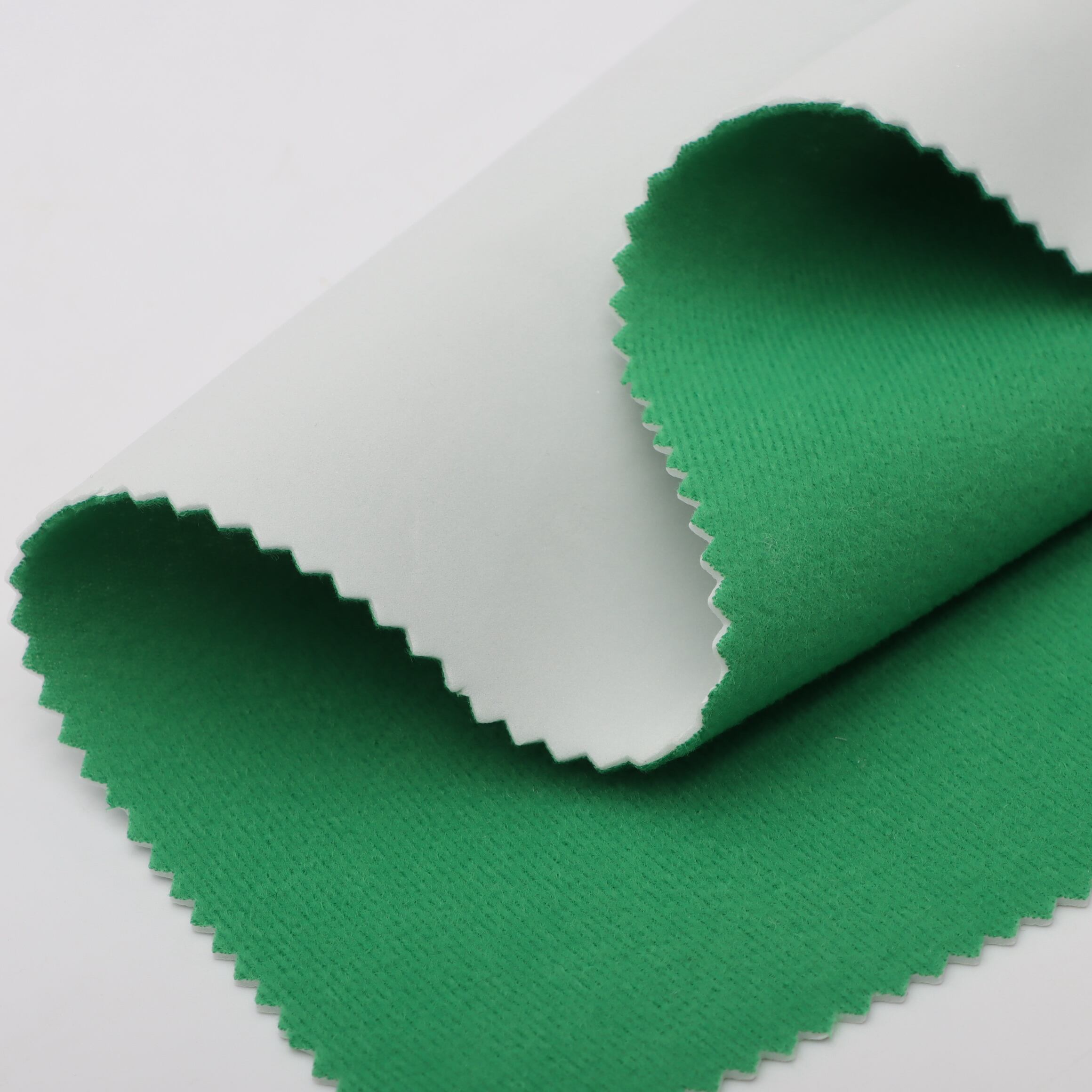

foam textile

Foam textile represents a revolutionary advancement in material science, combining the cushioning properties of foam with the versatility of traditional textiles. This innovative material features a unique cellular structure that creates countless microscopic air pockets throughout its composition, resulting in exceptional comfort and performance characteristics. The manufacturing process involves incorporating foam elements directly into the textile structure, creating a seamless integration that maintains breathability while adding substantial cushioning properties. These materials typically consist of polyurethane or similar polymeric foams combined with various fiber types, resulting in a product that offers both structural support and flexibility. The foam textile's structure allows for excellent moisture management, thermal regulation, and pressure distribution, making it ideal for various applications across multiple industries. From automotive seating to medical support surfaces, foam textiles have demonstrated remarkable versatility in meeting diverse performance requirements. The material's ability to conform to different shapes while maintaining its supportive properties has made it particularly valuable in ergonomic applications. Additionally, modern foam textiles incorporate advanced features such as antimicrobial treatments, fire retardancy, and enhanced durability, further expanding their utility in specialized applications.