headliner foam fabric

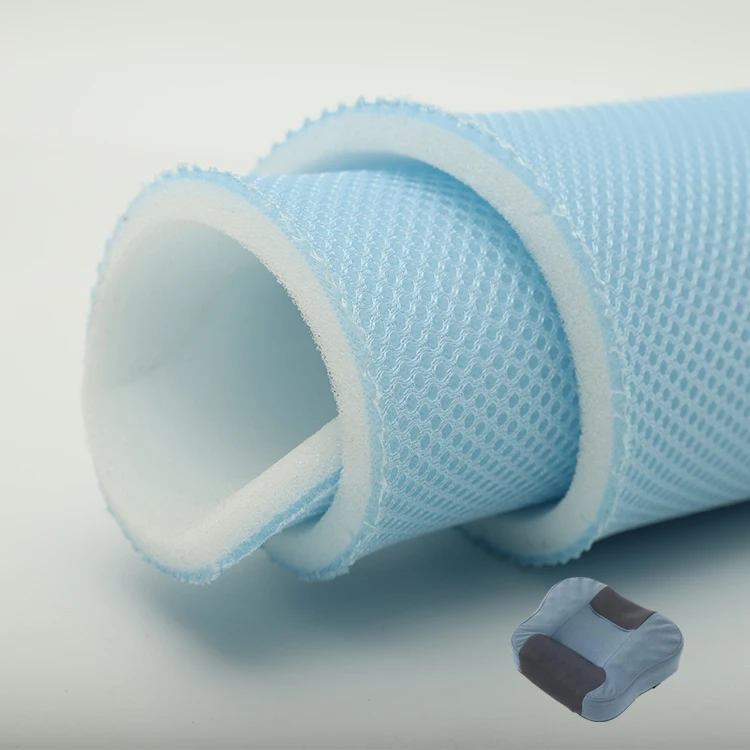

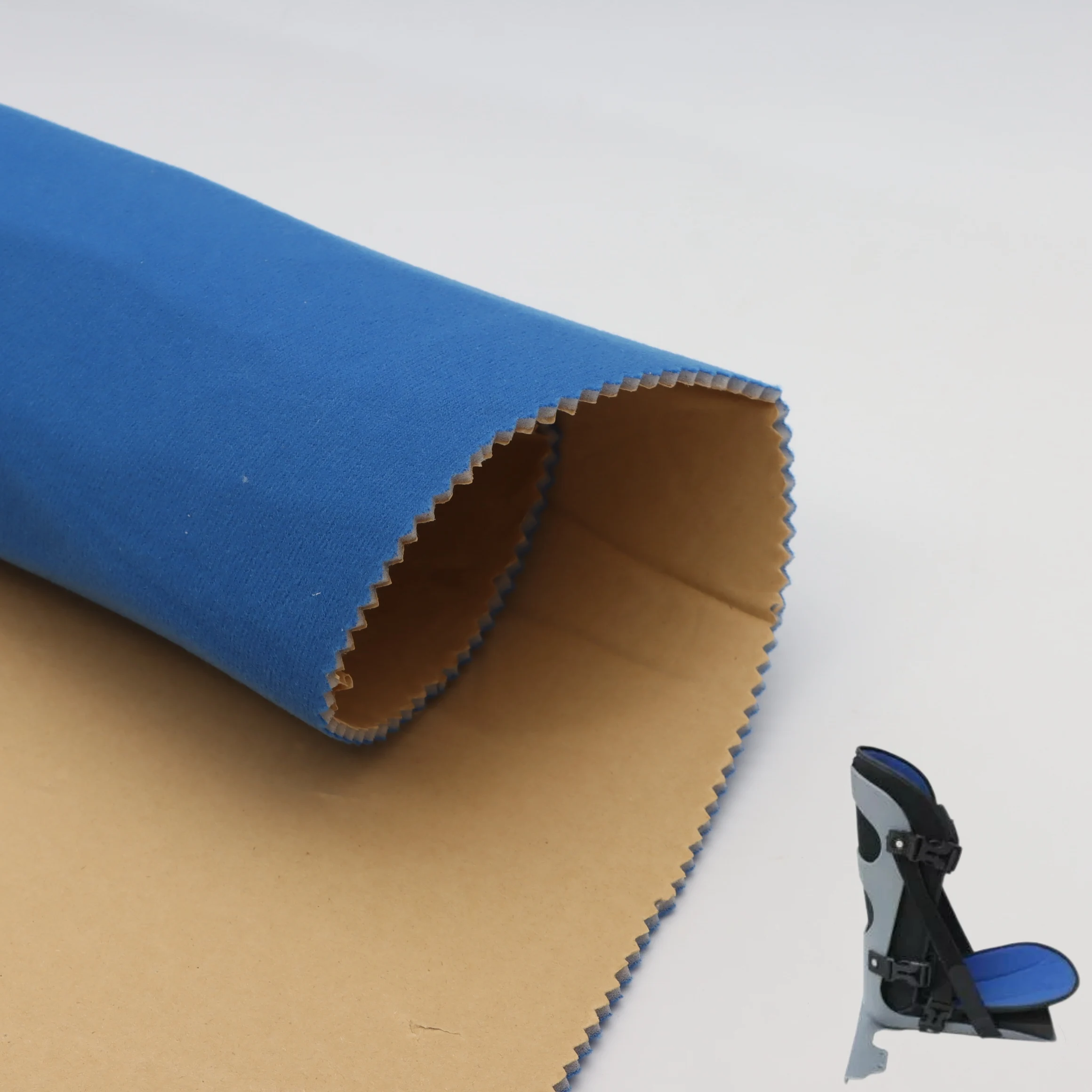

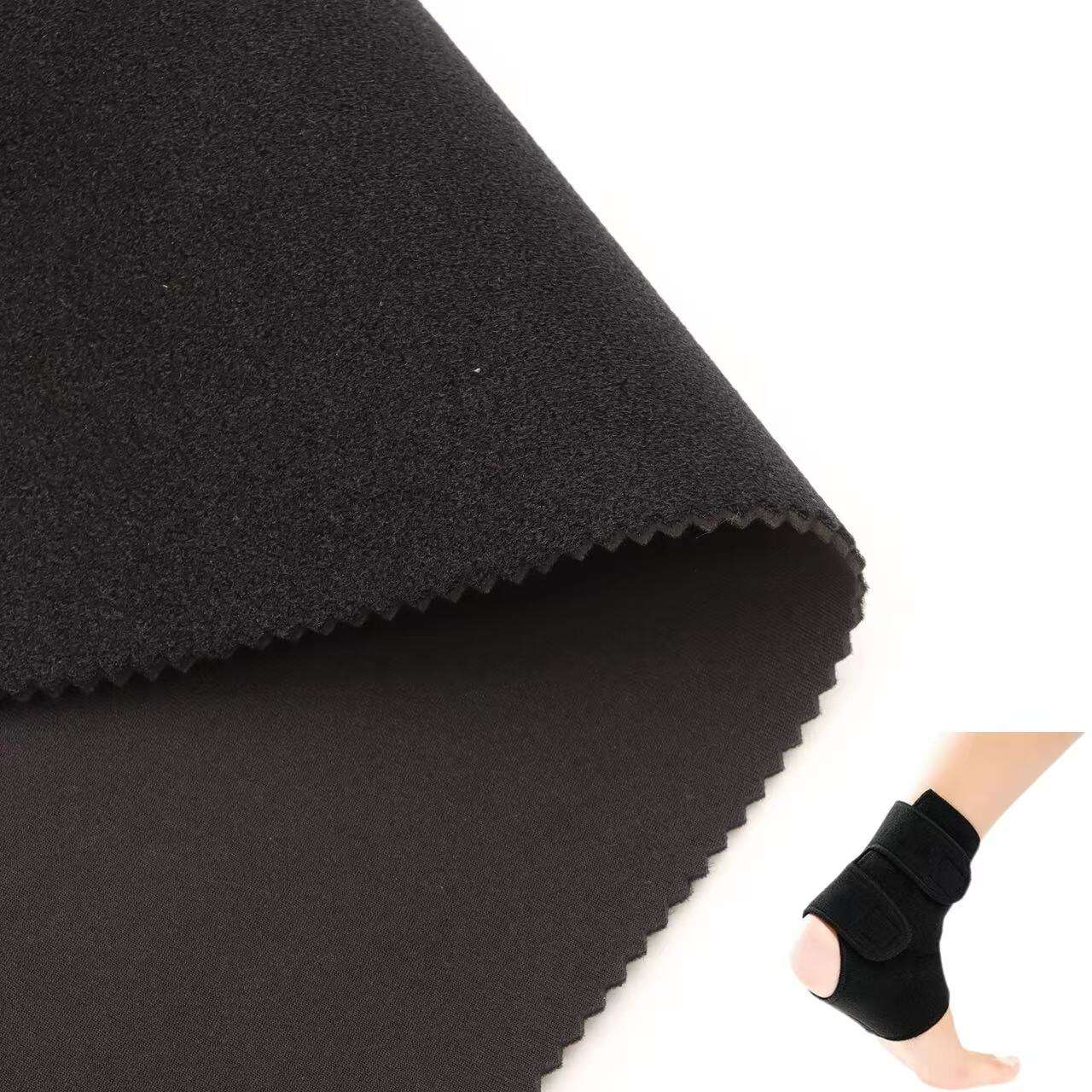

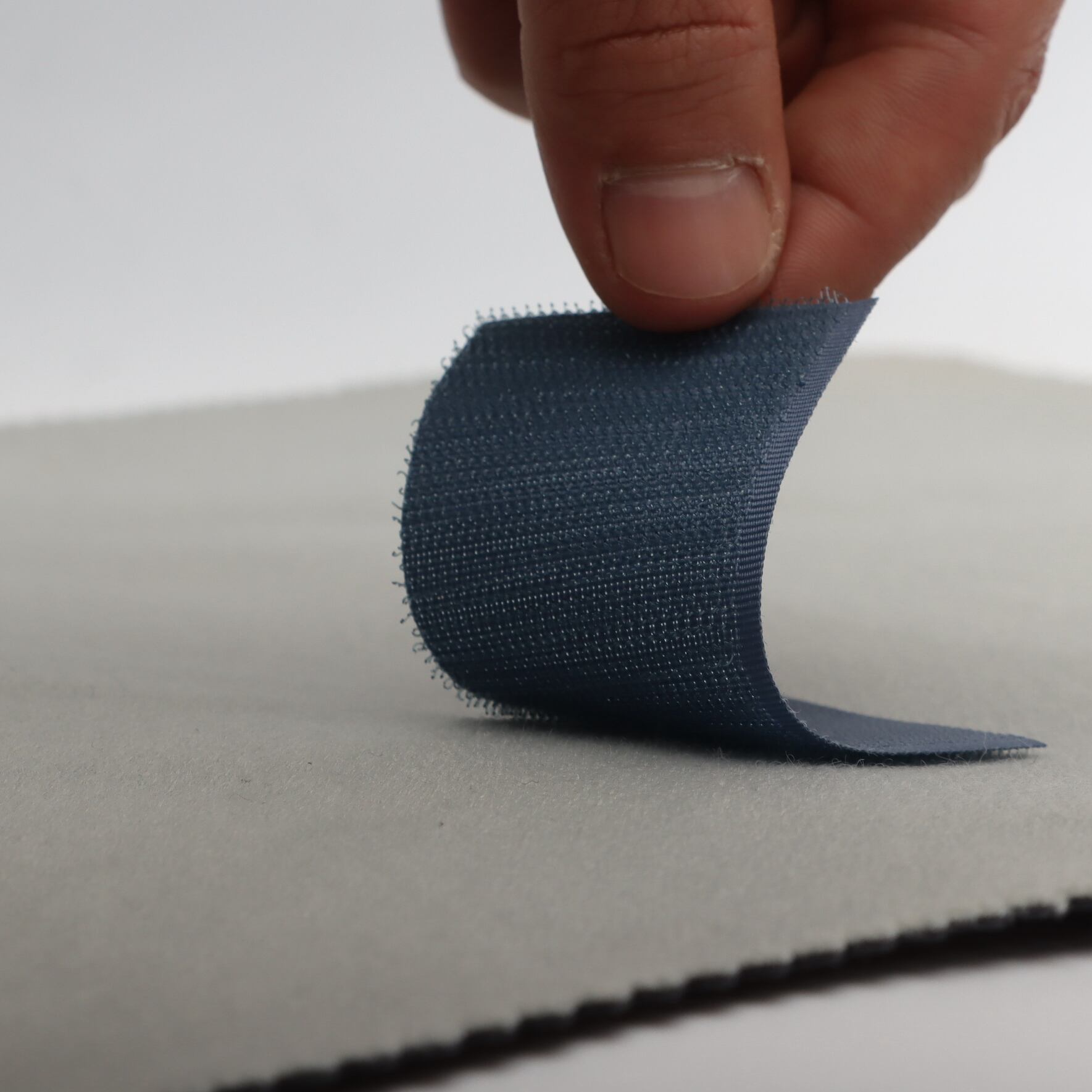

Headliner foam fabric represents a sophisticated composite material specifically engineered for automotive interior applications. This versatile material consists of three primary layers: a decorative surface fabric, a foam core, and a backing substrate. The foam core, typically made from polyurethane, provides essential acoustic absorption and thermal insulation properties while maintaining a lightweight structure. The material's construction allows for excellent formability, enabling it to conform to various roof geometries while maintaining structural integrity. The surface layer offers customizable aesthetics with different textures and colors, while providing resistance to UV radiation and environmental factors. Advanced manufacturing processes ensure consistent thickness and density distribution, crucial for maintaining uniform appearance and performance across the entire headliner surface. The material's inherent properties contribute to vehicle interior comfort by reducing noise transmission, managing temperature, and creating an aesthetically pleasing overhead surface. Modern headliner foam fabrics also incorporate antimicrobial treatments and stain-resistant properties, ensuring long-term durability and ease of maintenance. The material's composition is carefully balanced to meet strict automotive industry standards for safety, including flame retardancy and low VOC emissions.