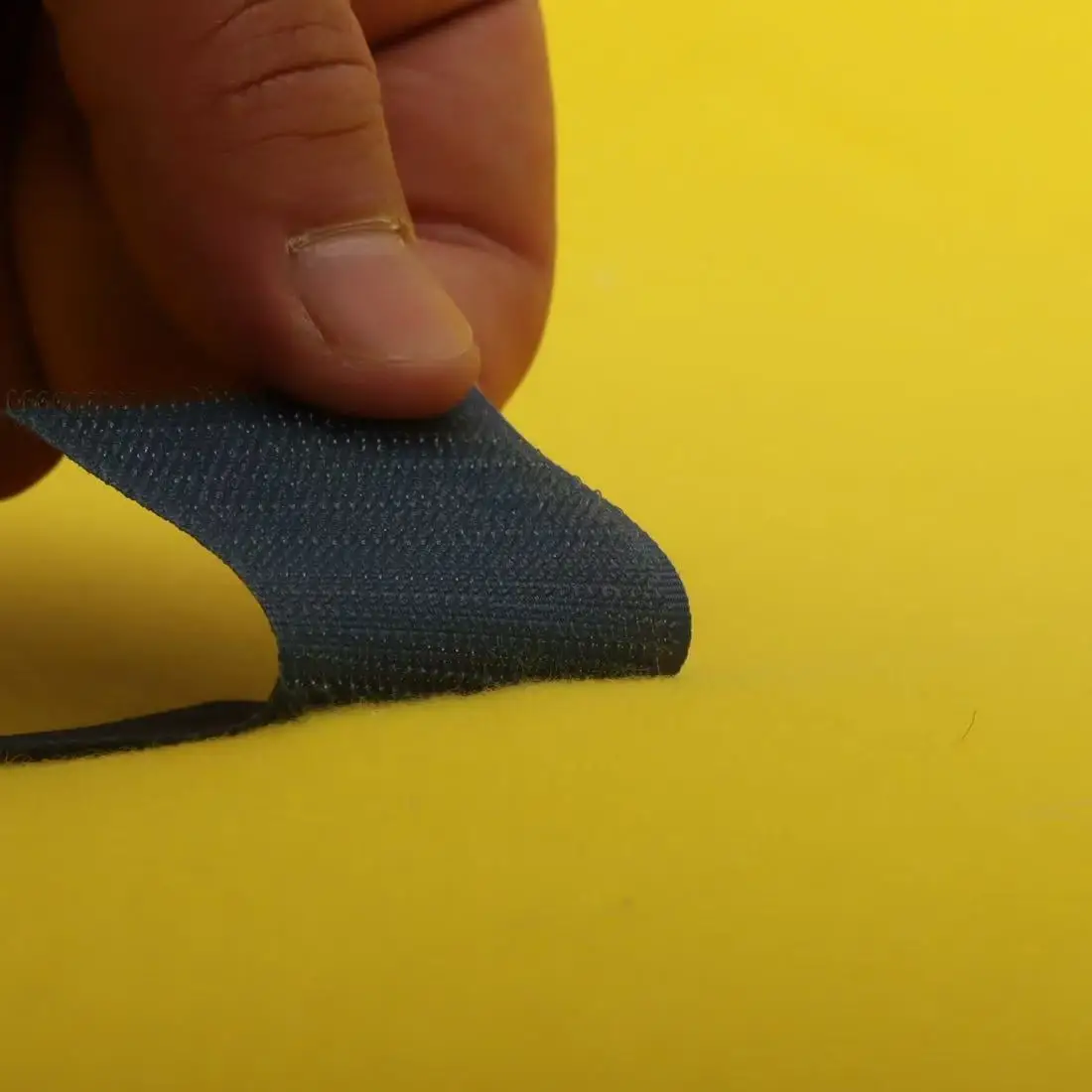

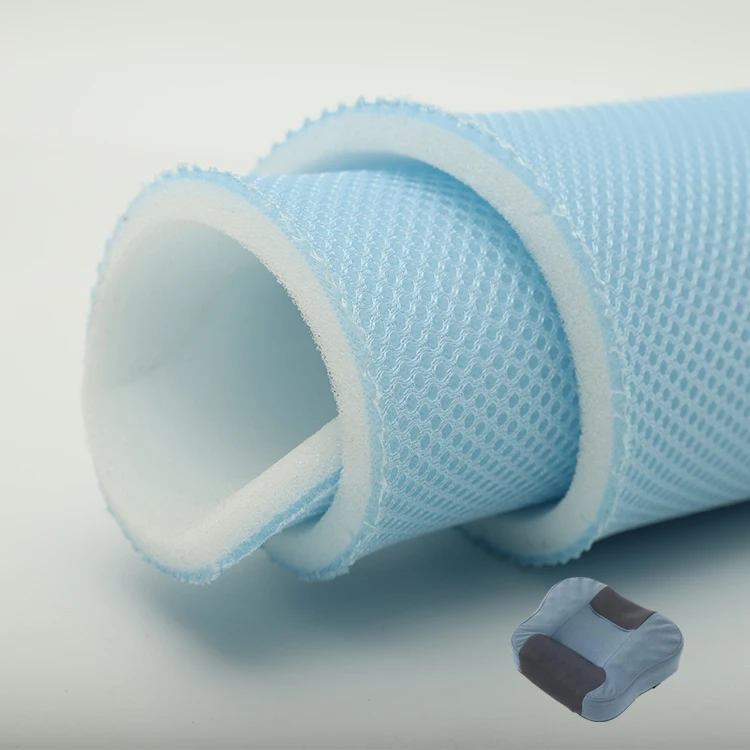

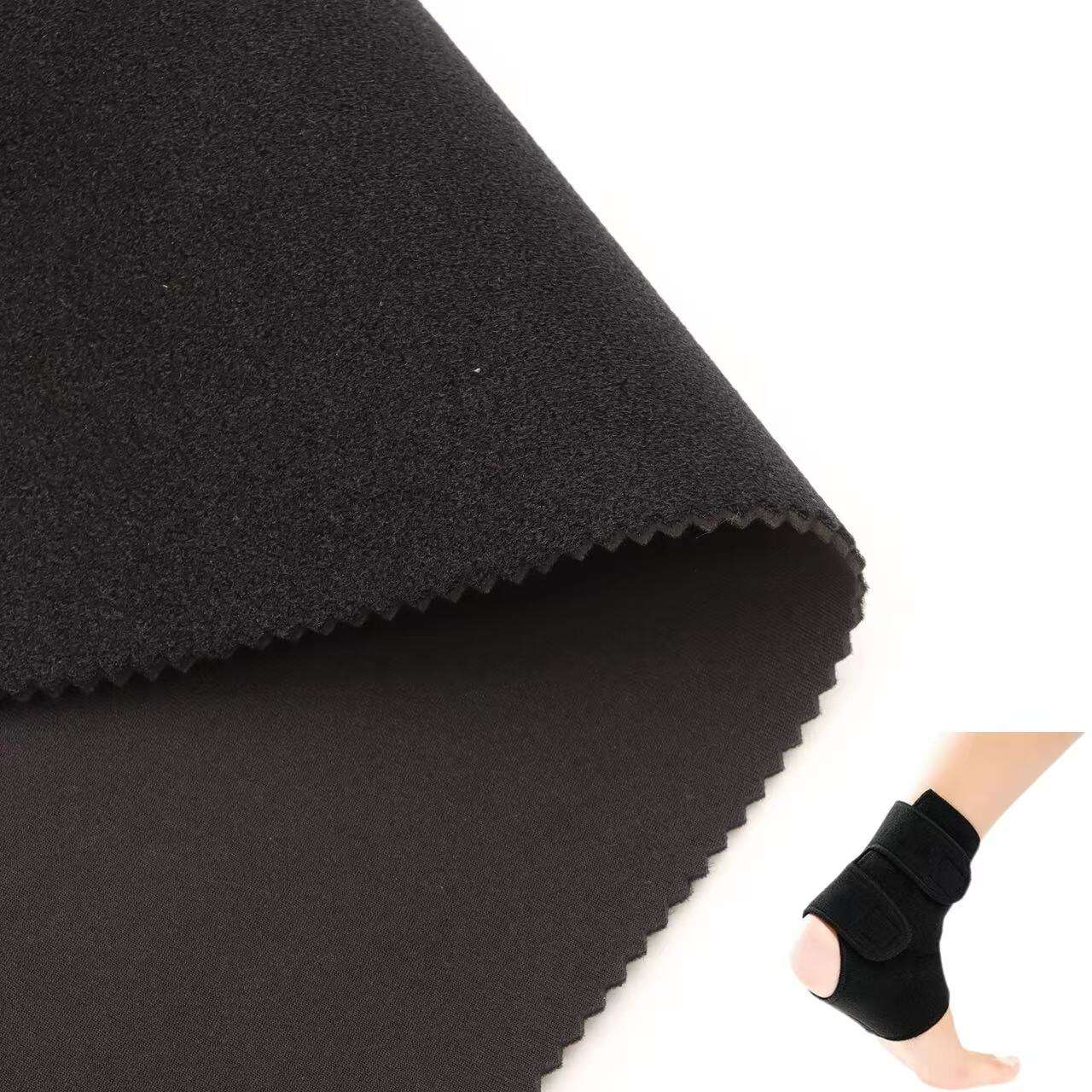

fabric with foam

Fabric with foam represents an innovative composite material that combines the flexibility and aesthetic appeal of traditional textiles with the supportive properties of foam technology. This versatile material consists of a foam layer bonded to fabric, creating a unique combination that enhances both comfort and functionality. The foam component typically features open-cell or closed-cell structures, providing varying degrees of cushioning, insulation, and moisture management. The fabric layer can be customized with different materials, from natural fibers to synthetic blends, offering diverse textures and appearances while maintaining the foam's beneficial properties. This combination creates a material that excels in applications requiring both softness and structure, making it ideal for furniture upholstery, automotive interiors, and specialized clothing. The manufacturing process ensures a strong bond between the foam and fabric layers, resulting in a durable product that maintains its properties through regular use. Advanced treatments can be applied to enhance specific characteristics such as water resistance, flame retardancy, or antimicrobial properties, further expanding its practical applications.