foam fabricland

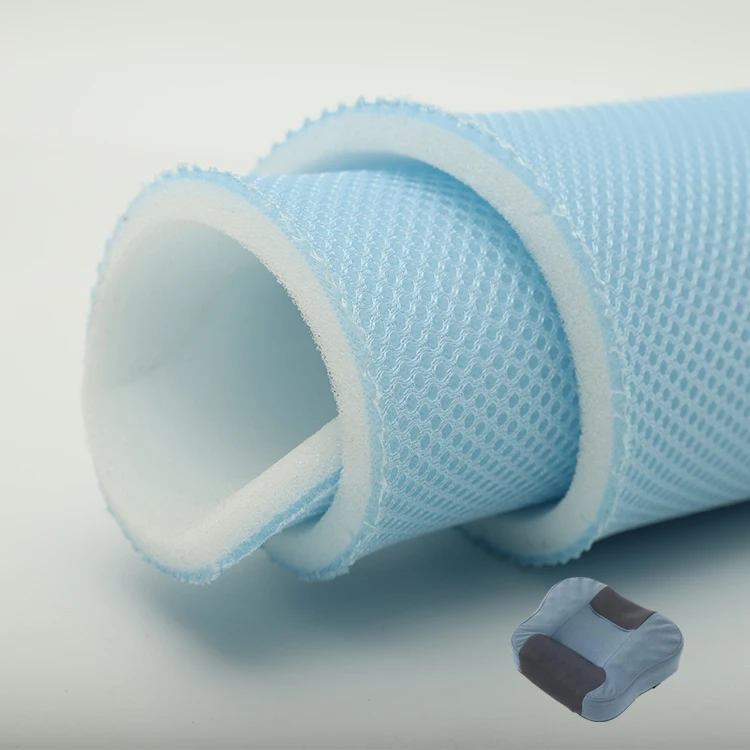

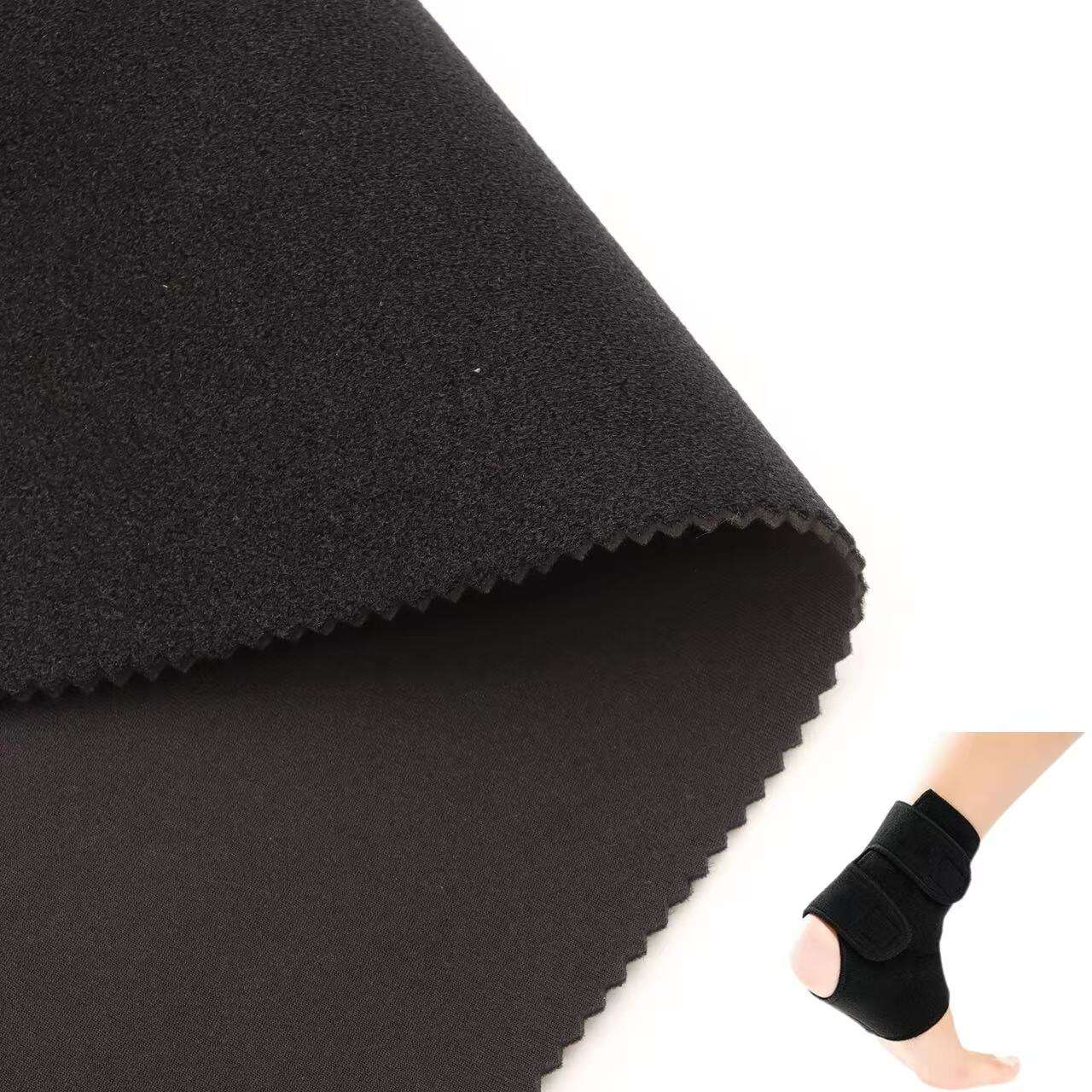

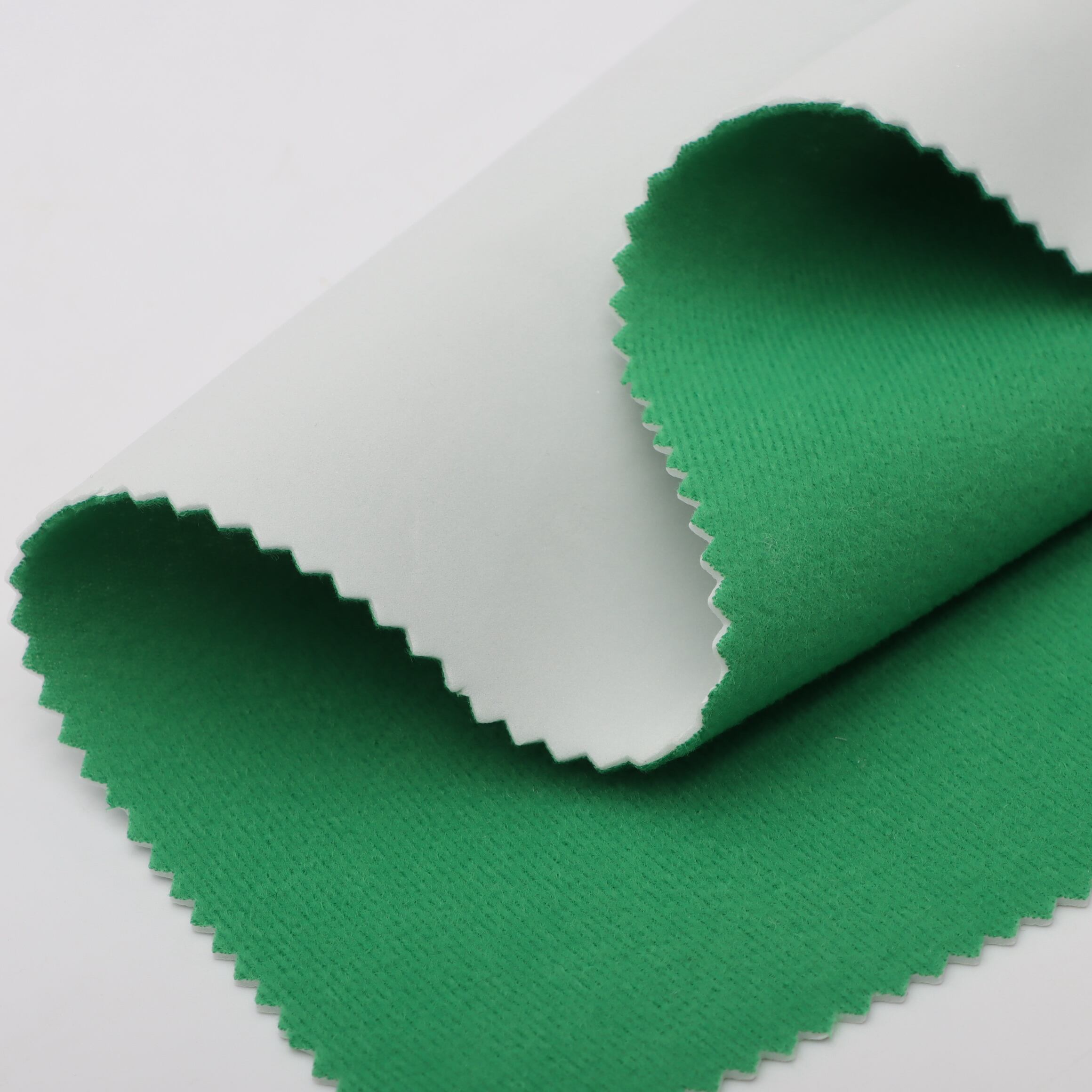

Foam Fabricland represents a cutting-edge manufacturing facility specializing in the production and customization of foam materials for diverse applications. This state-of-the-art facility combines advanced technology with expert craftsmanship to create precision-engineered foam solutions. The facility utilizes computer-aided design systems and automated cutting equipment to ensure exceptional accuracy in foam fabrication. With capabilities spanning from simple foam cutting to complex shape molding, Foam Fabricland serves industries including furniture manufacturing, packaging, automotive, medical equipment, and acoustic treatment. The facility's advanced machinery can process various foam types, including polyurethane, memory foam, and specialized technical foams. Quality control measures are implemented at every production stage, ensuring consistent product excellence. The facility's climate-controlled environment maintains optimal conditions for foam processing, while sophisticated testing equipment verifies material properties and performance characteristics. Additionally, Foam Fabricland offers comprehensive consulting services to help clients select the most suitable foam materials and manufacturing processes for their specific applications.