Versatile Application Integration

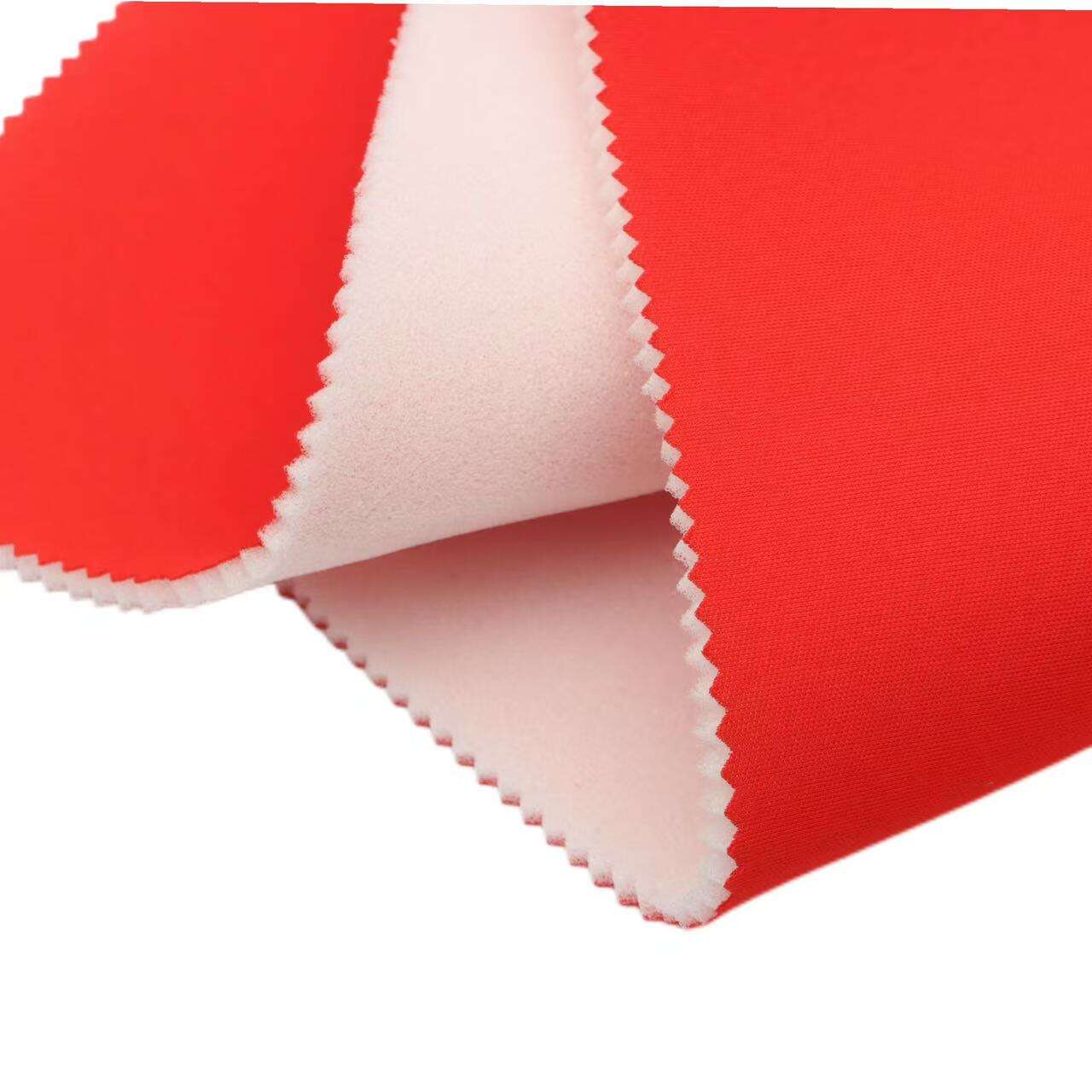

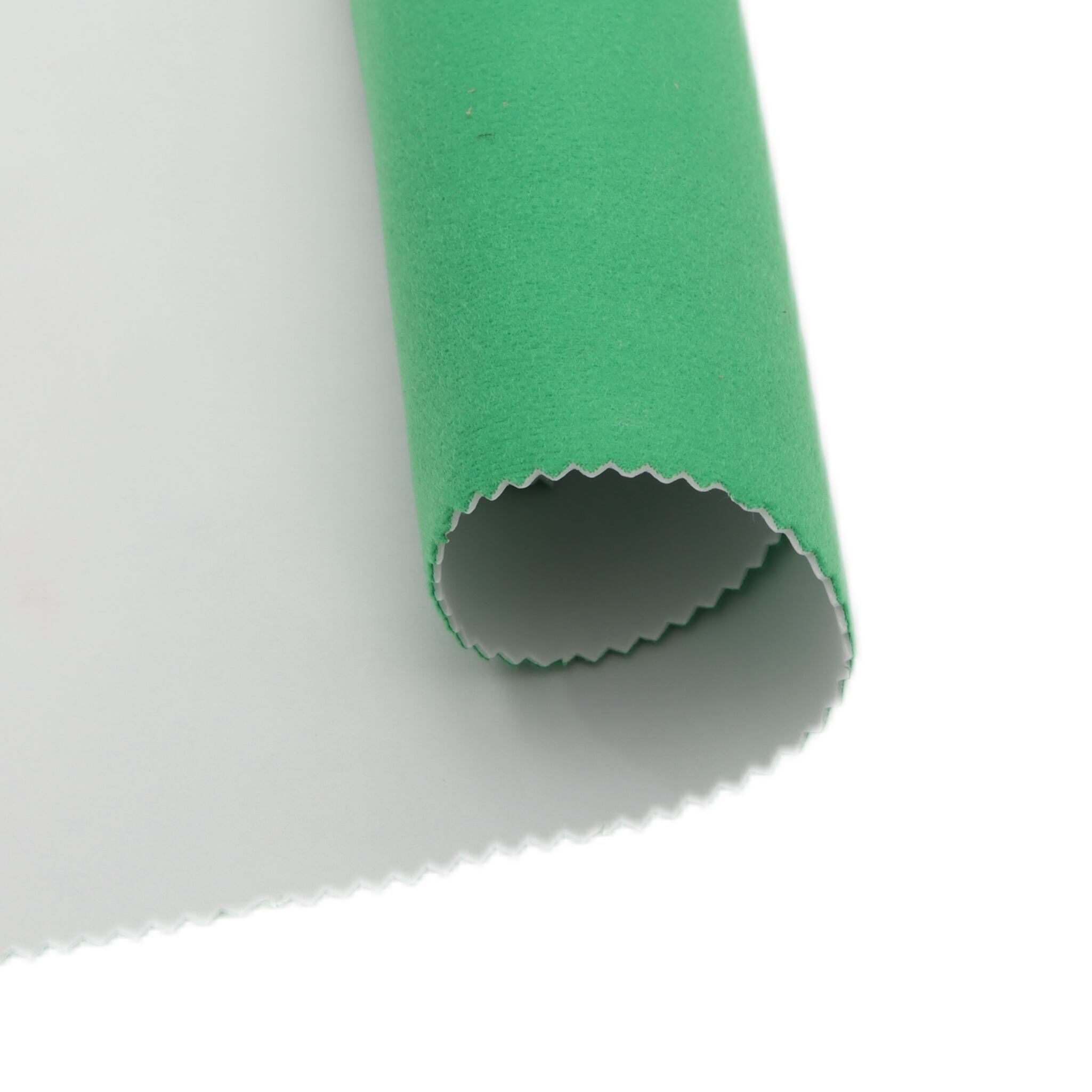

The exceptional versatility of headliner foam backing makes it suitable for an extensive range of applications across multiple industries. Its adaptability is demonstrated through compatible bonding with diverse substrate materials, including plastics, metals, fabrics, and composite materials. The foam's structural properties can be customized during manufacturing to meet specific requirements for density, thickness, and performance characteristics. Advanced processing techniques allow for precise cutting and shaping, enabling complex geometric configurations while maintaining uniform performance properties. This versatility extends to installation methods, with options for pressure-sensitive adhesives, heat activation, or mechanical fastening systems, providing flexibility in application approaches across different manufacturing environments.