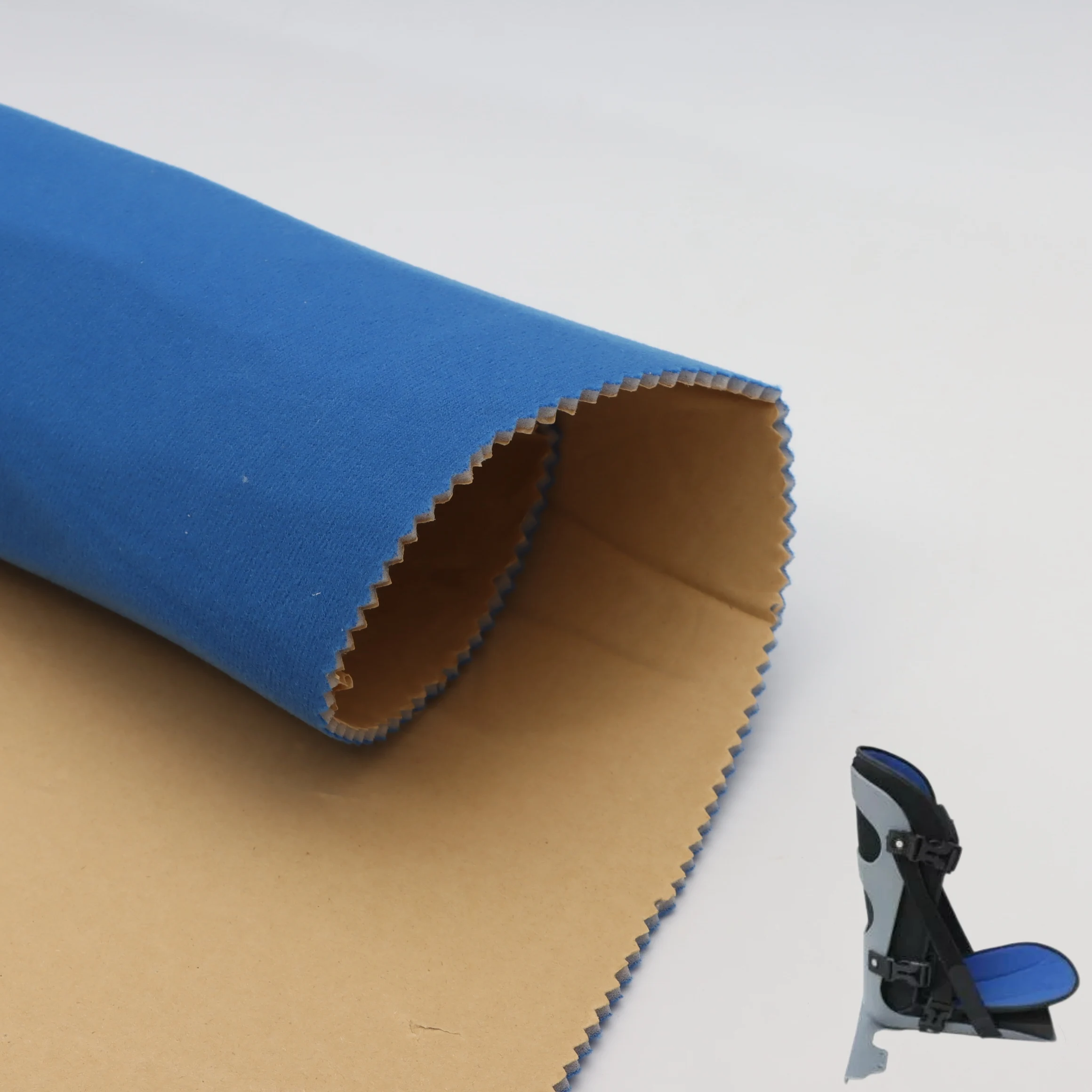

eva foam laminated fabric

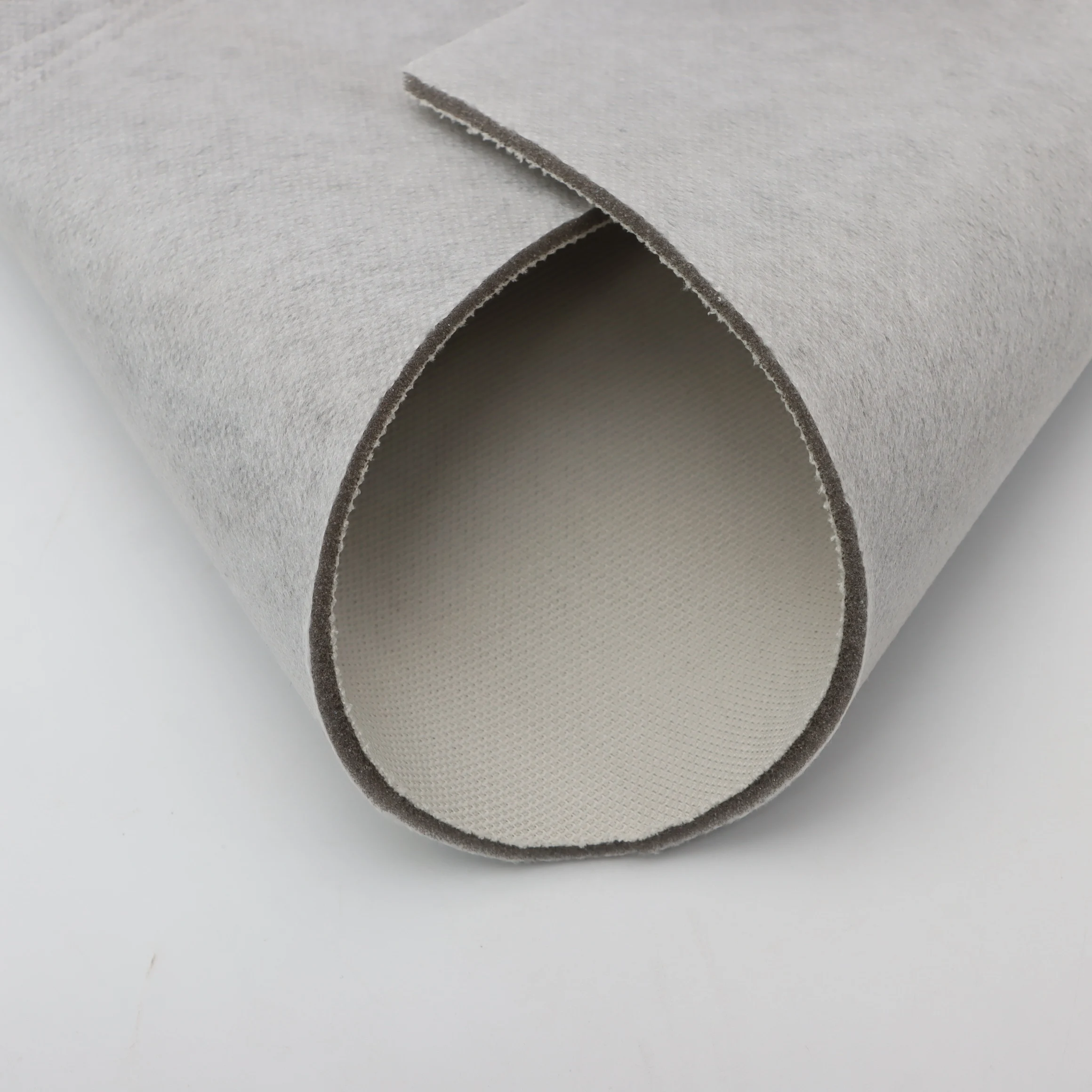

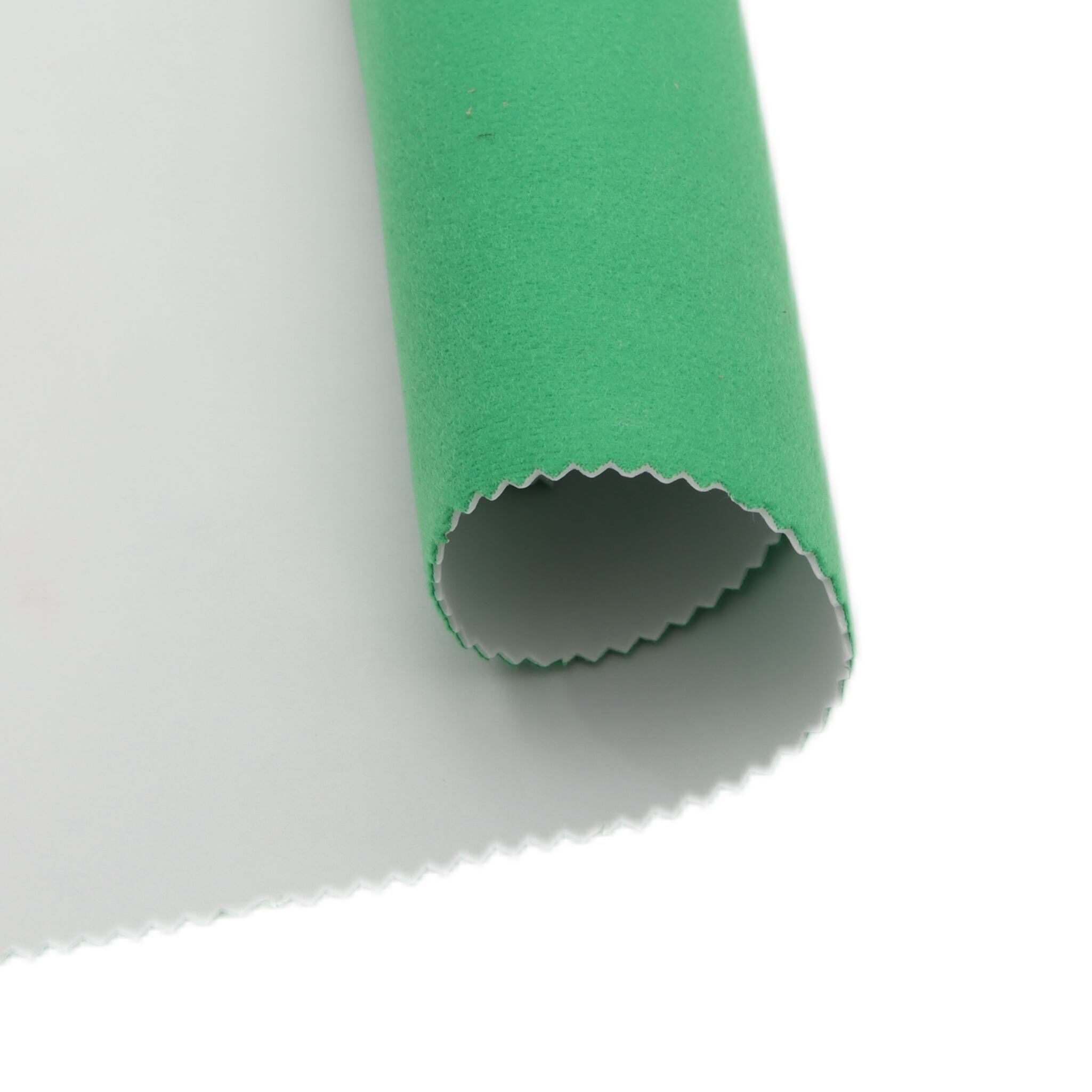

EVA foam laminated fabric represents a cutting-edge composite material that combines the durability of EVA (Ethylene Vinyl Acetate) foam with various fabric materials through advanced lamination processes. This versatile material features a unique construction where a layer of EVA foam is permanently bonded to fabric surfaces, creating a robust and flexible composite. The lamination process ensures superior adhesion between the foam and fabric layers, resulting in a material that offers exceptional durability and performance characteristics. The EVA foam core provides excellent cushioning and shock absorption properties, while the fabric outer layers contribute to aesthetic appeal and additional functionality. This innovative material finds extensive applications across multiple industries, from sports equipment and protective gear to footwear and automotive interiors. The fabric layer can be customized with different materials, including polyester, nylon, or natural fibers, allowing manufacturers to achieve specific performance requirements. The thickness and density of the EVA foam can also be adjusted to meet various application needs, making it an incredibly versatile solution for designers and manufacturers. The material's inherent water resistance, combined with its lightweight nature and excellent insulation properties, makes it particularly suitable for outdoor and athletic applications.