wholesale foam laminated fabric for bra

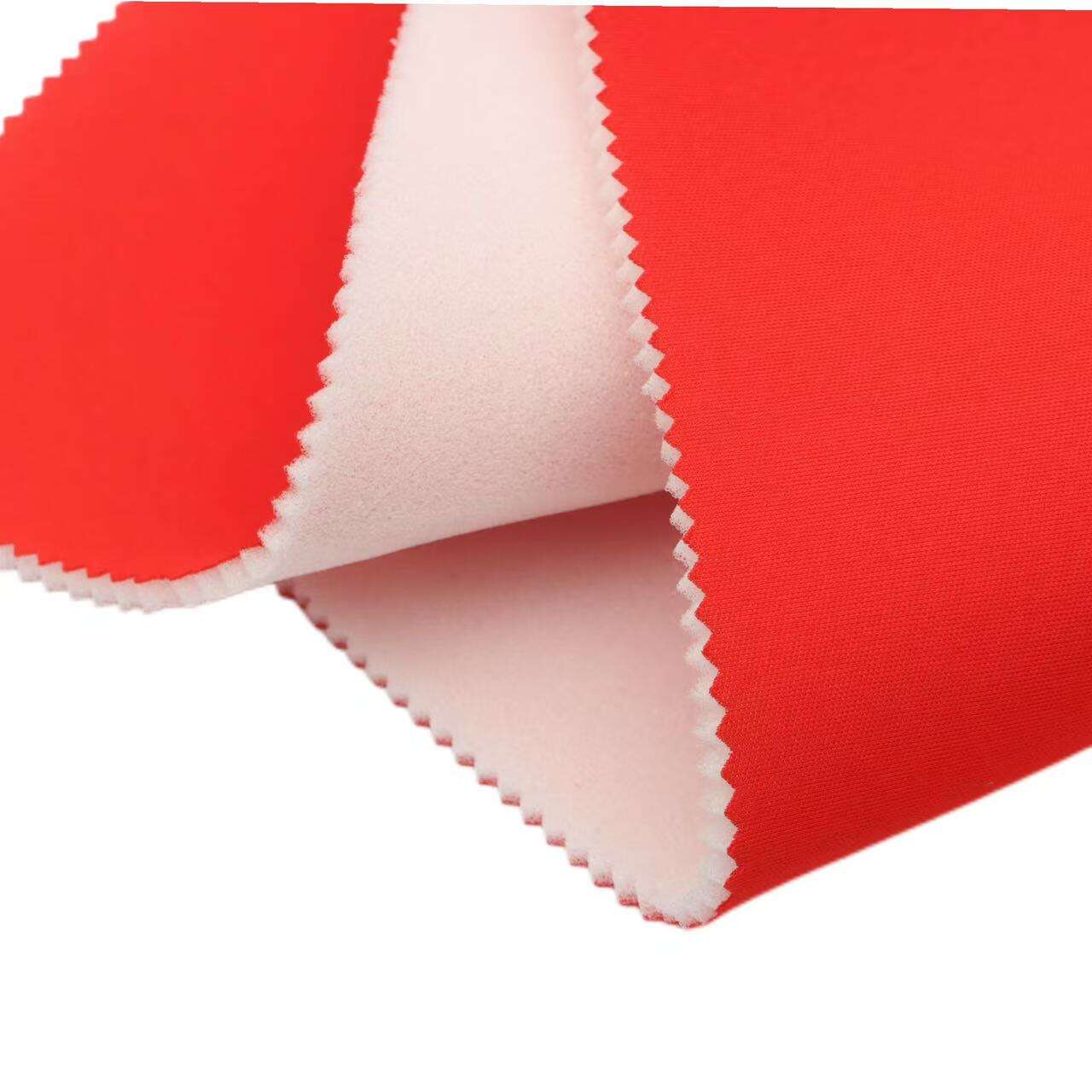

Wholesale foam laminated fabric for bras represents a revolutionary advancement in intimate apparel manufacturing, combining comfort, durability, and aesthetic appeal. This specialized material consists of a foam core that's precisely bonded with fabric layers through an advanced lamination process, creating a seamless and smooth foundation for bra construction. The fabric features exceptional shape retention properties while maintaining breathability, ensuring long-lasting comfort for the end user. The manufacturing process involves careful selection of foam density and thickness, coupled with compatible fabric types to achieve optimal support and flexibility. The material's structure allows for superior moisture management and temperature regulation, making it ideal for everyday wear. Additionally, the foam laminated fabric offers excellent cut-and-sew capabilities, enabling manufacturers to create various bra styles and sizes efficiently. The material's versatility extends to accommodating different design requirements, from push-up styles to wireless options, while maintaining consistent quality and performance. With its ability to provide both structure and comfort, this wholesale fabric has become an essential component in modern bra manufacturing, meeting the demanding standards of both producers and consumers.