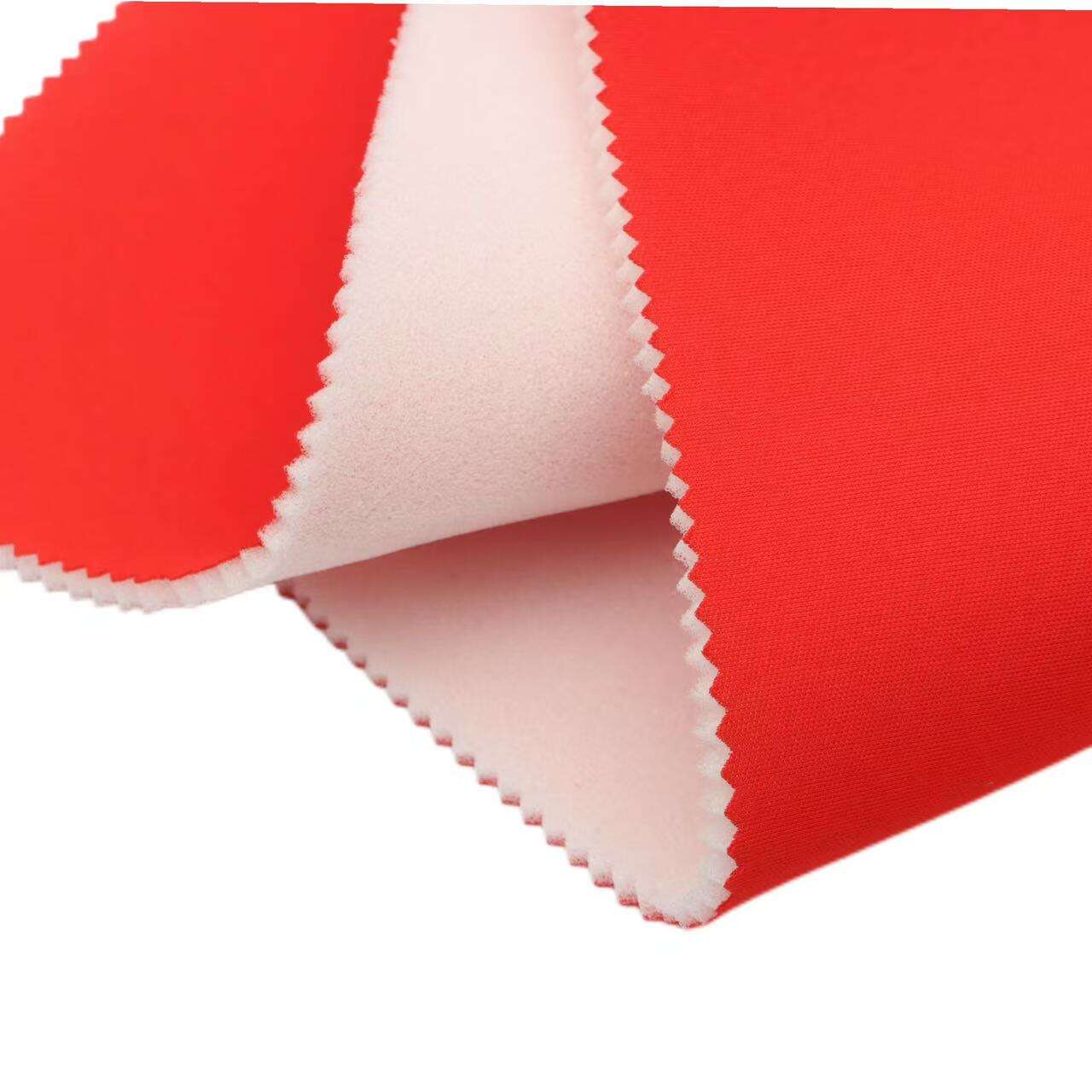

bra production material laminated fabric

Laminated fabric is a cutting-edge material revolutionizing bra production through its innovative multi-layer construction. This specialized textile combines multiple layers of fabric bonded together using advanced lamination technology, creating a seamless and supportive foundation for intimate apparel. The process involves precisely fusing different fabric layers under controlled temperature and pressure conditions, resulting in a composite material that maintains its shape while offering superior comfort. The material typically consists of a soft, skin-friendly inner layer, a stabilizing middle layer, and a decorative outer layer, each contributing to specific performance aspects. This engineering marvel eliminates the need for traditional seams and stitching, reducing potential irritation points while enhancing the garment's durability. The material's technical properties include moisture-wicking capabilities, controlled stretch, and excellent recovery characteristics, ensuring long-lasting performance through multiple wear and wash cycles. In bra manufacturing, laminated fabric enables designers to create smoother silhouettes, invisible edges, and better support structures without compromising on comfort or aesthetics.