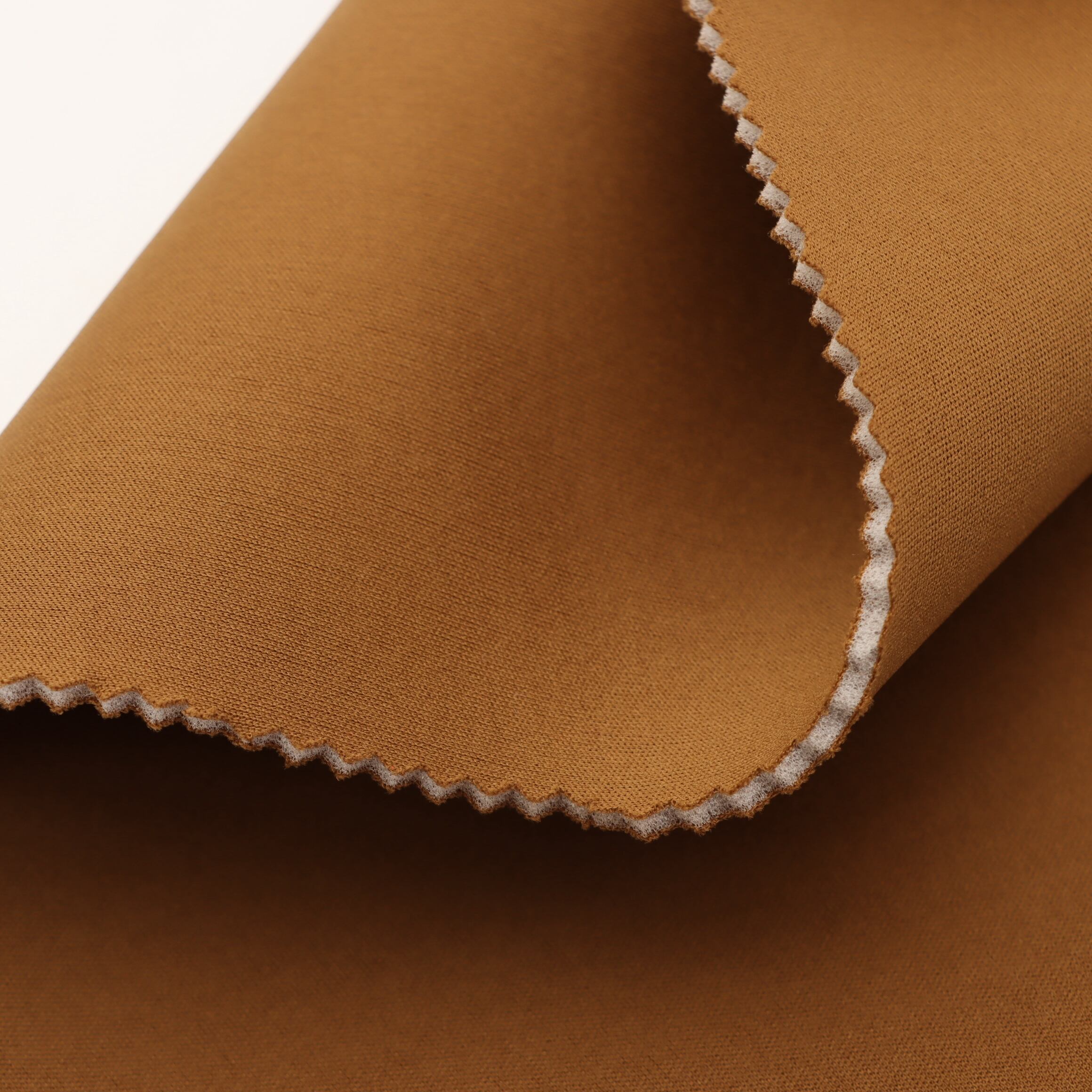

bra foam

Bra foam represents a revolutionary component in modern lingerie manufacturing, engineered to provide essential structure and comfort in brassieres. This specialized material combines lightweight polyurethane foam with advanced molding technologies to create seamless, supportive cups that maintain their shape while offering maximum comfort. The foam's unique cellular structure allows for optimal breathability while providing necessary insulation and modesty. Modern bra foam incorporates various densities and thicknesses, enabling manufacturers to create different styles from everyday basics to push-up varieties. The material undergoes sophisticated manufacturing processes, including heat molding and lamination, to achieve desired shapes and support levels. Its versatility allows for integration with various fabric types and can be engineered to specific requirements, such as moisture-wicking properties or enhanced durability. The foam's adaptability makes it suitable for various applications, from sports bras to luxury lingerie, while maintaining its structural integrity through multiple wash cycles. This innovative material has revolutionized the lingerie industry by enabling the creation of seamless, comfortable, and supportive undergarments that meet diverse consumer needs.