lingerie foam fabric custom supplier

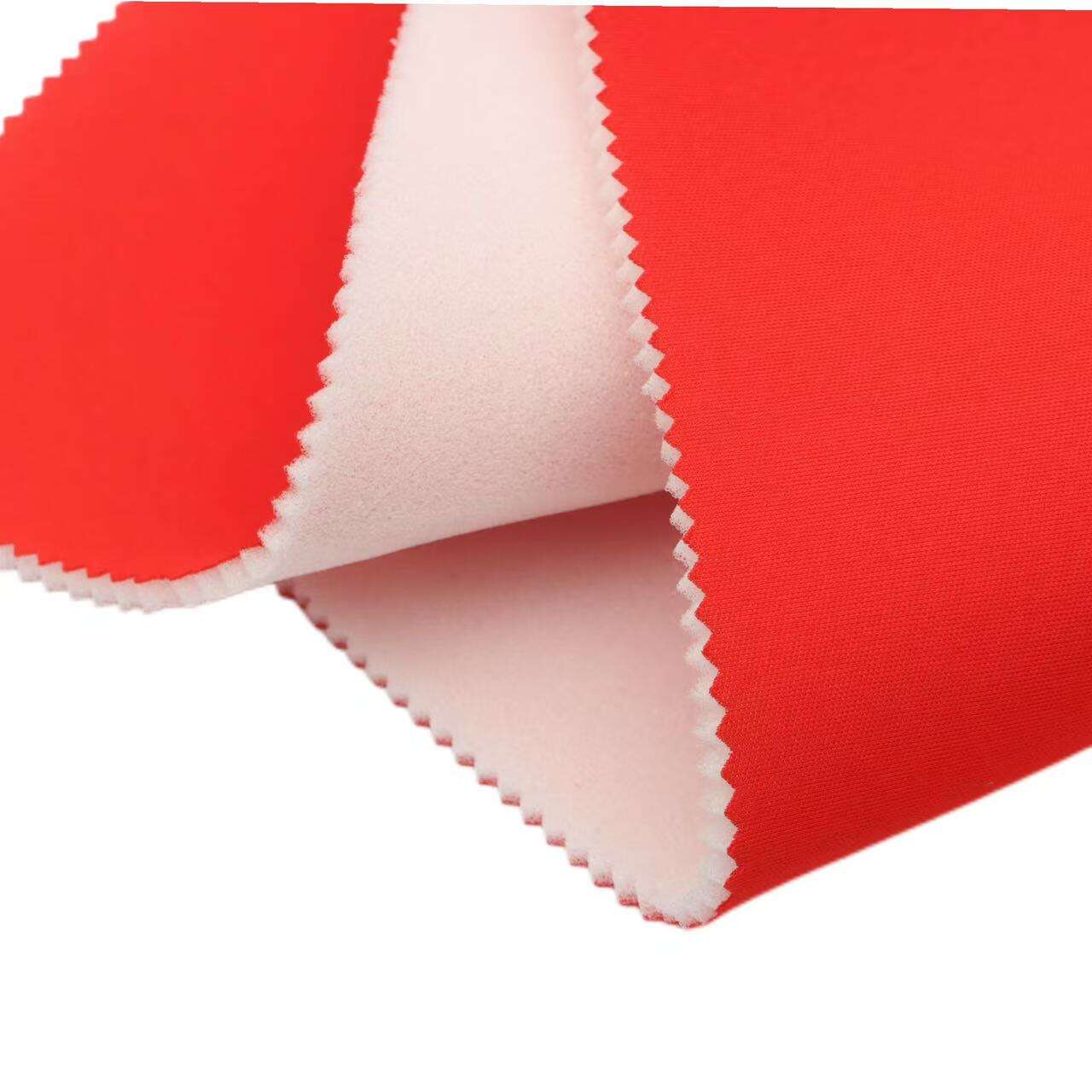

A lingerie foam fabric custom supplier specializes in producing high-quality, innovative foam materials specifically designed for intimate apparel manufacturing. These suppliers utilize advanced technology and state-of-the-art equipment to create custom foam solutions that meet diverse requirements in terms of thickness, density, and flexibility. The foam fabrics are engineered to provide optimal comfort, support, and shape retention while maintaining breathability and moisture-wicking properties. These suppliers typically offer a comprehensive range of services, including material development, pattern cutting, and custom molding processes. The foam materials undergo rigorous quality control measures to ensure consistency in performance and durability. They incorporate various technical features such as seamless edge finishing, multi-density construction, and specialized surface treatments for enhanced comfort and functionality. The applications extend beyond traditional bra cups to include shoulder straps, wing components, and innovative shapewear solutions. Modern lingerie foam fabric suppliers also emphasize sustainability, often utilizing eco-friendly materials and production processes to meet growing environmental concerns in the fashion industry.