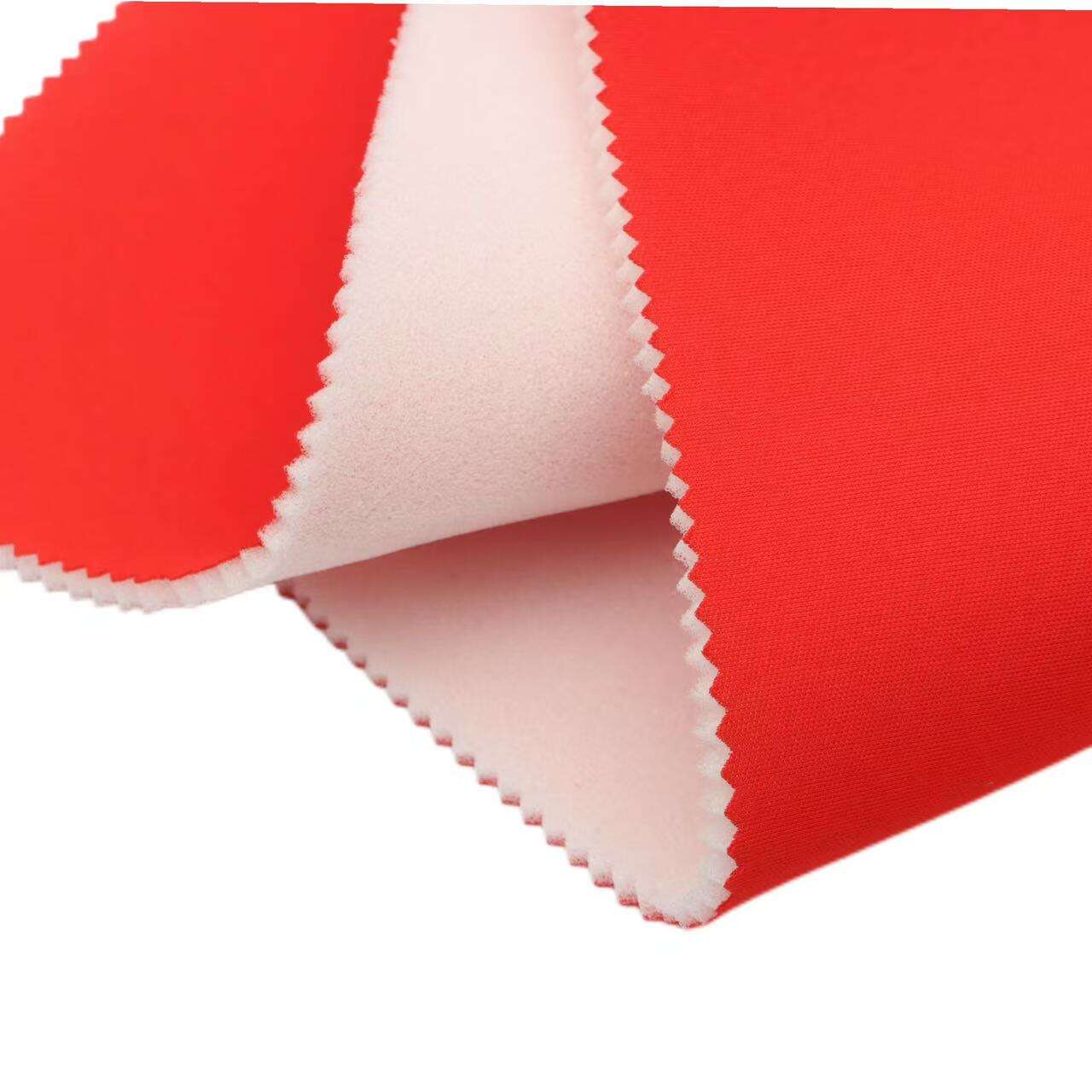

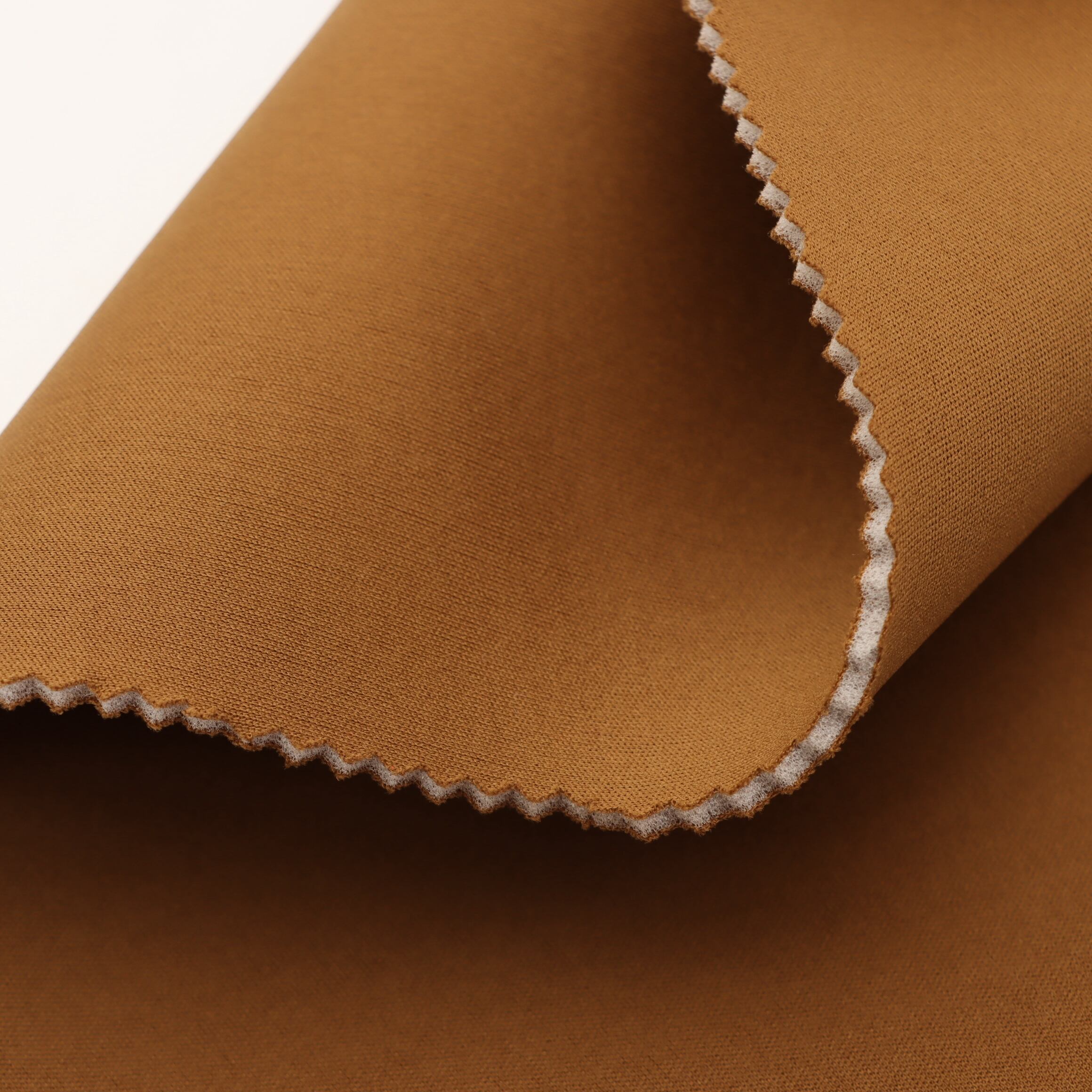

bra foam for sewing

Bra foam for sewing represents an essential component in lingerie and swimwear construction, offering both structure and comfort to garments. This specialized material consists of lightweight, moldable foam sheets specifically designed for intimate apparel creation. The foam typically ranges from 3mm to 12mm in thickness, providing various options for different styling needs. Made from high-quality polyester or polyurethane materials, these foam sheets feature excellent shape retention properties while maintaining breathability. The material's unique construction allows it to be easily cut, shaped, and sewn without losing its structural integrity. Modern bra foam incorporates advanced moisture-wicking technology, ensuring comfort during extended wear. The foam's surface is specially treated to prevent friction with fabric layers, making it ideal for both hand and machine sewing applications. Its versatility extends beyond traditional bra making, finding applications in sports apparel, costume design, and various other fashion applications requiring shape and support. The material's durability ensures that garments maintain their intended form through multiple washing cycles, while its flexibility allows for natural movement and comfort.