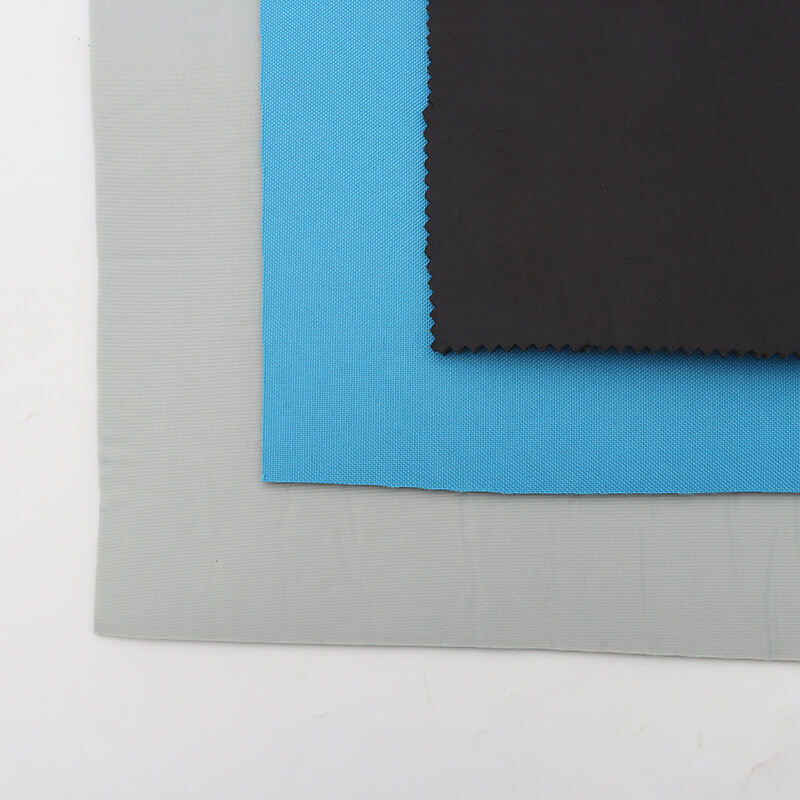

oem foam laminated polyester

OEM foam laminated polyester represents a cutting-edge composite material that combines the durability of polyester with the cushioning properties of foam through an advanced lamination process. This innovative material features multiple layers precisely bonded together, creating a versatile product that offers both structural integrity and comfort. The manufacturing process involves carefully selecting high-quality polyester fabric and combining it with specialized foam layers using heat and pressure-sensitive adhesives. The resulting material exhibits exceptional dimensional stability, moisture resistance, and thermal insulation properties. The foam component provides excellent shock absorption and padding, while the polyester layer ensures durability and aesthetic appeal. This material finds extensive applications in automotive interiors, furniture upholstery, sports equipment, protective gear, and various industrial applications. The lamination process ensures that the foam and polyester layers remain permanently bonded, preventing delamination even under demanding conditions. The material can be customized in terms of thickness, density, and surface texture to meet specific requirements, making it highly adaptable for different end-use applications.