bra foam fabric supplier china

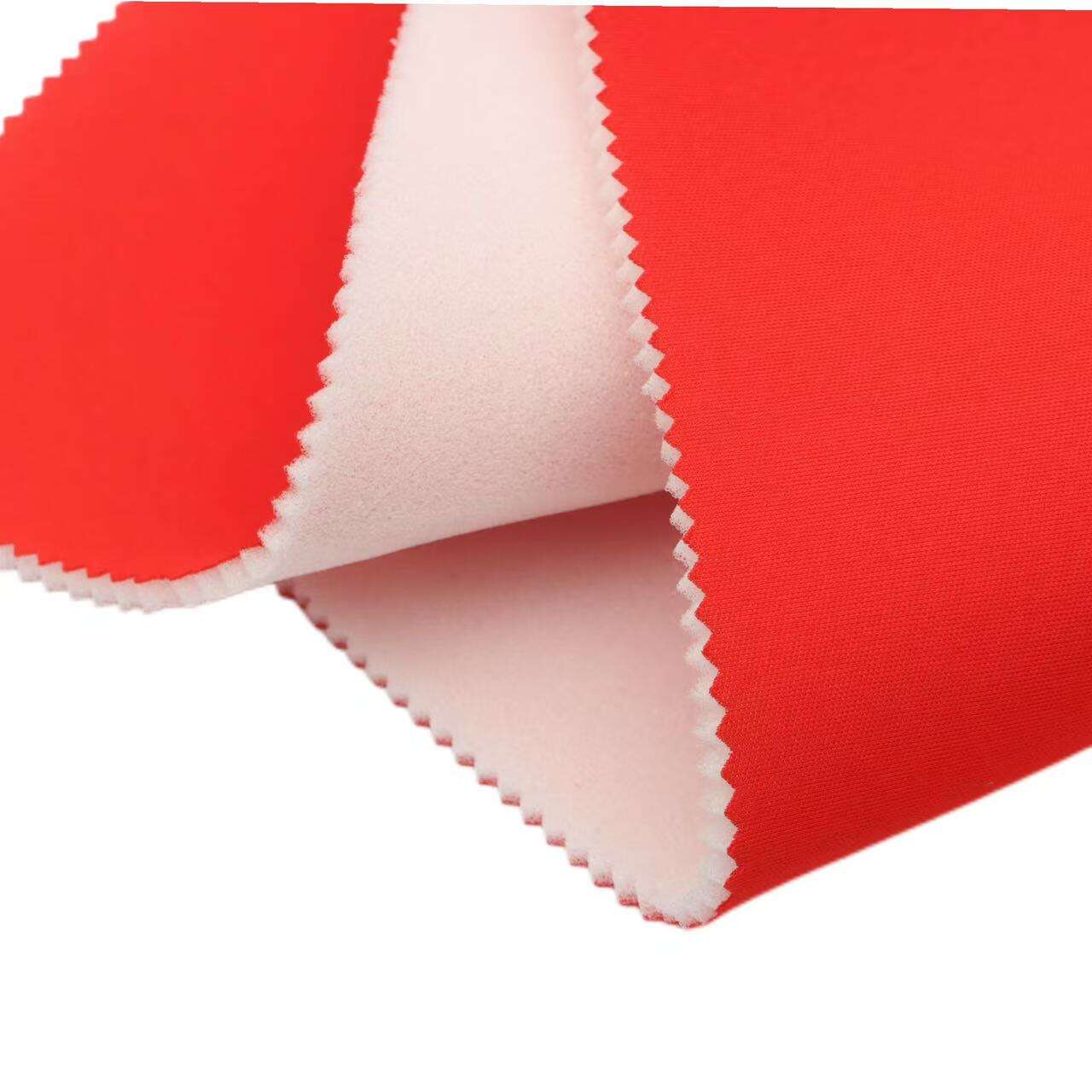

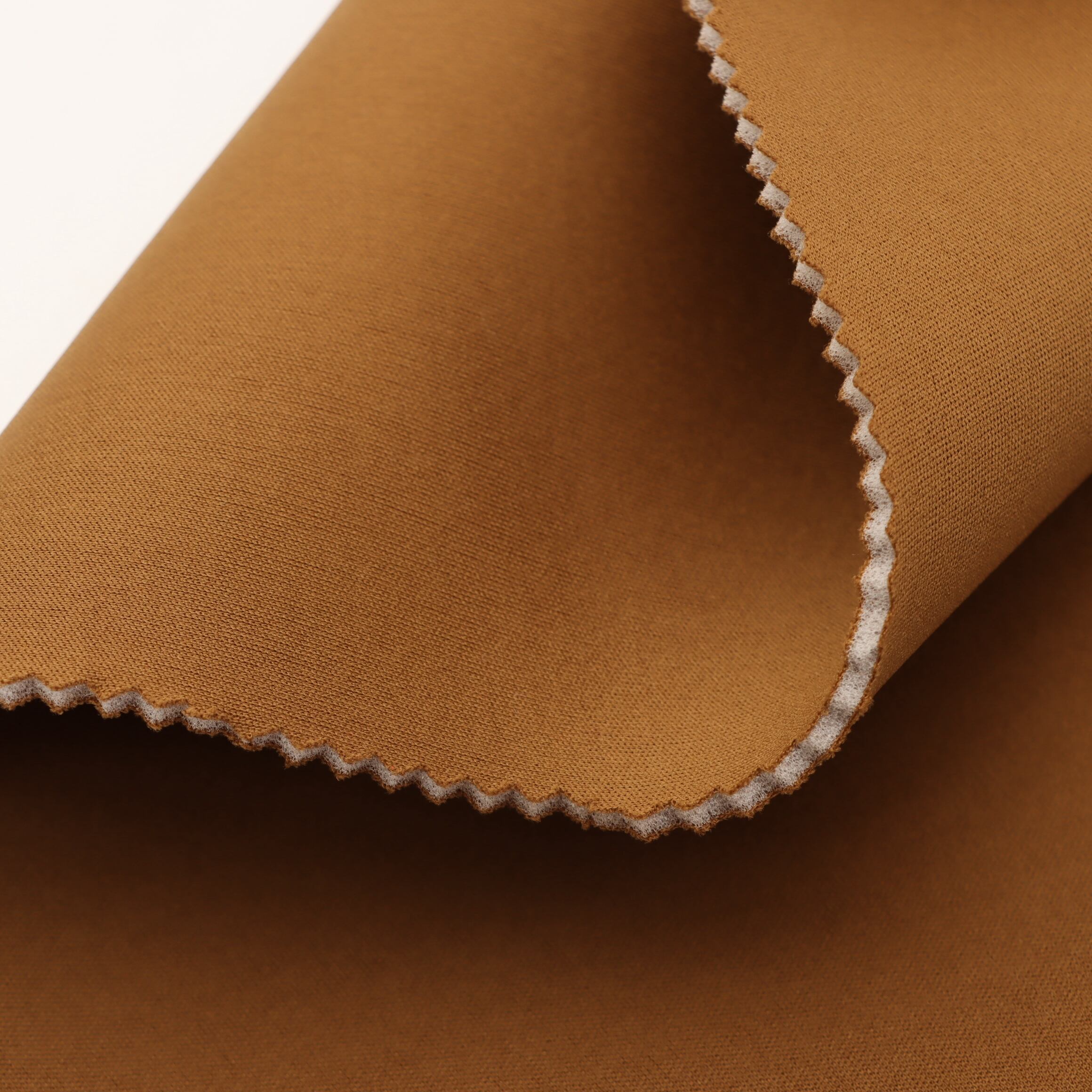

A bra foam fabric supplier in China represents a crucial link in the global intimate apparel manufacturing chain, specializing in the production and distribution of high-quality foam materials essential for bra construction. These suppliers utilize advanced manufacturing technologies to create diverse foam varieties, including molded cups, push-up padding, and seamless foam sheets. The materials undergo rigorous quality control processes, ensuring consistency in density, flexibility, and durability. Modern facilities employ state-of-the-art equipment for precision cutting, molding, and lamination, resulting in products that meet international standards. These suppliers typically offer customization options, including various thicknesses, densities, and shapes to accommodate different bra designs and styles. The foam fabrics are engineered to maintain their shape, provide comfort, and offer necessary support while remaining lightweight and breathable. Additionally, many suppliers incorporate eco-friendly manufacturing processes and sustainable materials, responding to growing environmental concerns in the fashion industry.