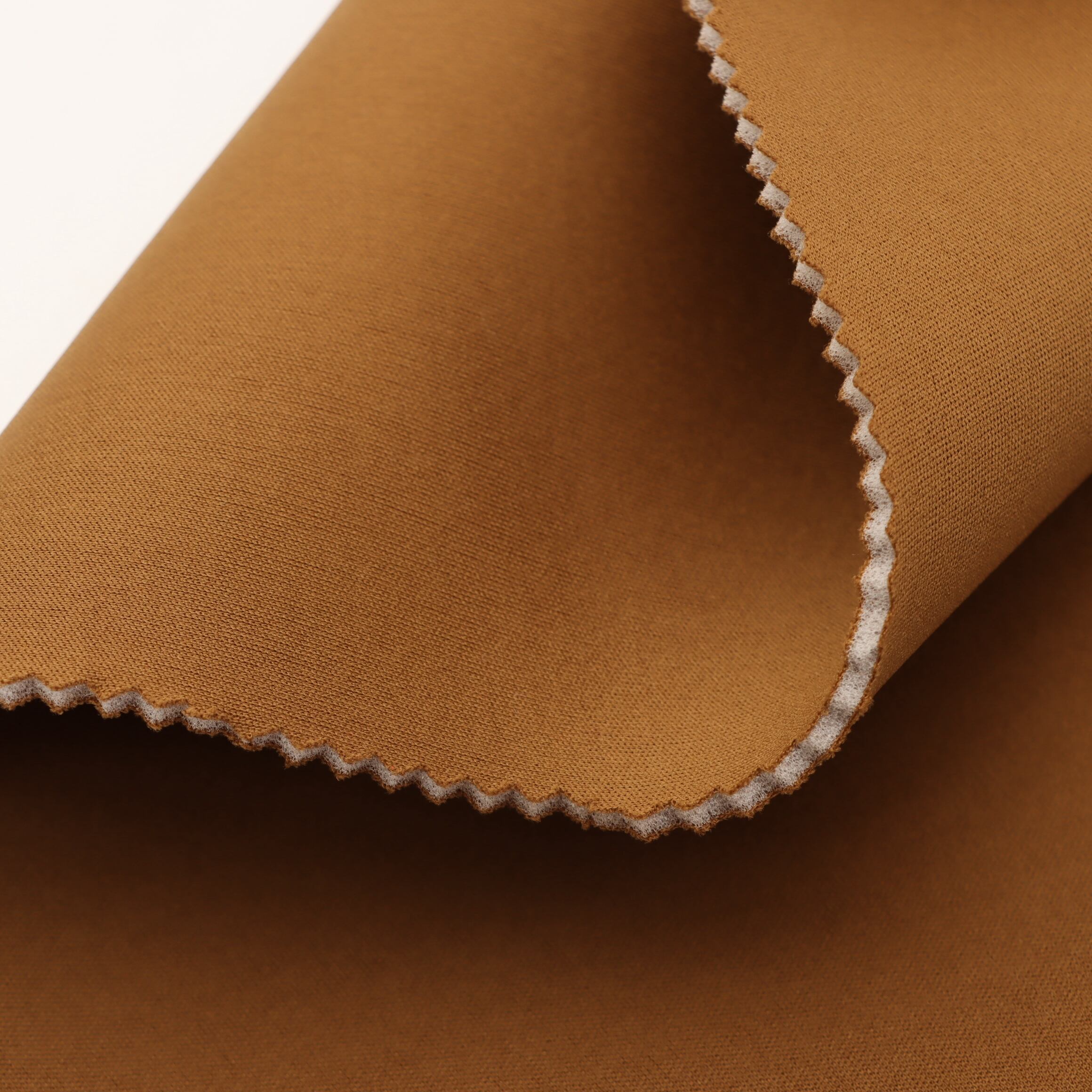

bonded bra cup fabric exporter

A bonded bra cup fabric exporter specializes in providing high-quality, technologically advanced materials for intimate apparel manufacturing. These exporters utilize cutting-edge bonding technology to create seamless, durable bra cup fabrics that combine multiple layers of materials into a single, cohesive structure. The process involves precision thermal bonding techniques that eliminate traditional stitching, resulting in smooth, comfortable cup materials that maintain their shape and support. The exporters typically offer a comprehensive range of fabric options, including moisture-wicking materials, breathable meshes, and various density levels to meet different support requirements. Their production facilities are equipped with state-of-the-art bonding machines that ensure consistent quality and precise specifications for each fabric batch. Additionally, these exporters maintain strict quality control measures, conducting thorough testing for durability, wash resistance, and comfort factors. They typically serve global intimate apparel manufacturers, providing customized solutions for different market segments and style requirements. The fabrics exported are designed to meet international standards and regulations, ensuring compliance with industry requirements for both comfort and safety.