Industrial and technical garments serve critical functions across various sectors, from protective workwear to specialized sports equipment. One fundamental component that often determines the performance, comfort, and durability of these garments is the lining fabric. This essential layer works behind the scenes to enhance functionality, provide moisture management, and ensure wearer comfort in demanding environments. Understanding the role of lining fabric in industrial applications helps manufacturers and end-users make informed decisions about garment construction and performance specifications.

Understanding Lining Fabric in Technical Applications

Definition and Core Functions

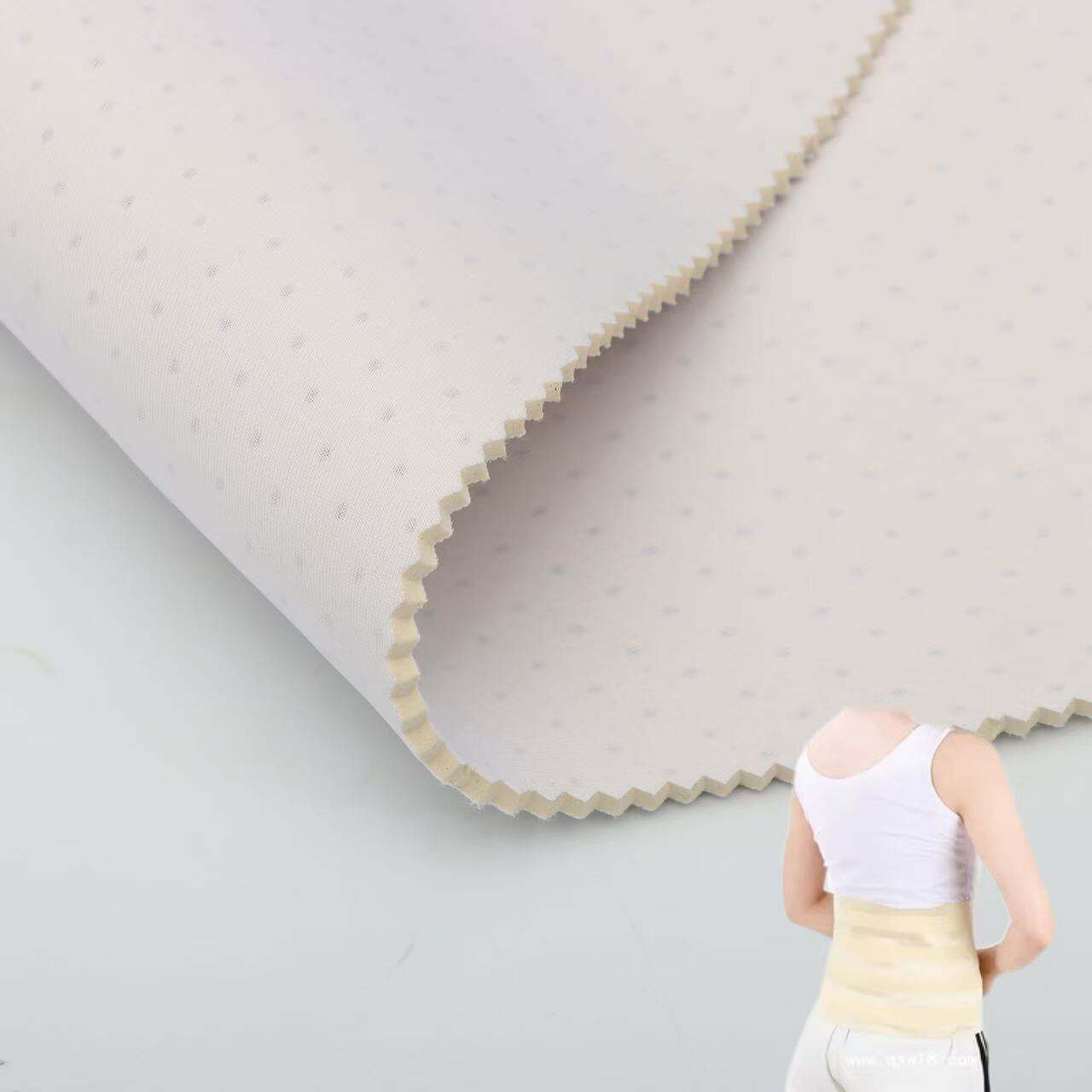

Lining fabric represents a specialized textile layer positioned between the outer shell and the wearer's skin or base clothing. In industrial contexts, this fabric serves multiple critical functions beyond simple comfort enhancement. The primary purpose includes moisture management, temperature regulation, and providing a smooth interface that reduces friction during movement. Modern lining fabric incorporates advanced materials science to deliver specific performance characteristics required in demanding work environments.

The technical specifications of lining fabric vary significantly based on application requirements. Industrial garments may require flame-resistant properties, chemical resistance, or enhanced breathability depending on the work environment. These fabrics often feature engineered structures that promote airflow while maintaining protective barriers against external hazards. The selection process involves careful consideration of factors including fiber composition, weave structure, and any specialized treatments applied during manufacturing.

Material Composition and Performance Characteristics

Contemporary lining fabric utilizes various synthetic and natural fiber combinations to achieve specific performance targets. Polyester-based linings offer excellent moisture-wicking properties and dimensional stability, making them ideal for high-activity applications. Nylon variants provide superior strength and abrasion resistance, particularly valuable in heavy-duty industrial garments. Some specialized applications incorporate aramid fibers or other high-performance materials to meet extreme temperature or chemical exposure requirements.

The engineering of lining fabric extends to surface treatments and structural modifications that enhance functionality. Antimicrobial treatments help prevent odor development during extended wear periods, while hydrophilic or hydrophobic coatings control moisture behavior. Textured surfaces can improve air circulation or provide additional insulation properties depending on the specific application needs. These advanced characteristics make lining fabric an integral component rather than a simple comfort addition.

Applications Across Industrial Sectors

Protective Workwear Integration

In protective workwear applications, lining fabric plays a crucial role in maintaining comfort while preserving safety features. Arc-rated garments require specialized linings that complement the outer shell's flame-resistant properties without compromising protection levels. The lining must provide thermal comfort while ensuring that heat transfer characteristics meet safety standards. This balance requires careful material selection and testing to verify performance under extreme conditions.

Chemical-resistant garments present unique challenges for lining fabric selection. The inner layer must resist degradation from chemical vapors while maintaining breathability and comfort. Some applications require barrier properties that prevent chemical penetration while others focus on rapid moisture evacuation to prevent heat stress. The compatibility between outer shell materials and lining fabric becomes critical in these demanding environments.

Sports and Recreation Equipment

Technical sports equipment relies heavily on advanced lining fabric systems to optimize athlete performance and comfort. Motorcycle protective gear, skiing equipment, and professional sports uniforms all incorporate sophisticated lining systems. These applications demand rapid moisture management, temperature control, and flexibility that moves with the athlete. The lining fabric must maintain its properties through repeated washing cycles and extended use periods.

Helmet liners represent a specialized application where lining fabric directly impacts safety and comfort. The material must provide cushioning while maintaining breathability and moisture management. Anti-bacterial properties become essential for equipment shared among multiple users or worn for extended periods. The dimensional stability of the lining fabric ensures consistent fit and protection throughout the equipment's service life.

Technical Performance Requirements

Moisture Management Systems

Effective moisture management represents one of the most critical functions of industrial lining fabric. The fabric must rapidly transport perspiration away from the skin while preventing external moisture penetration. This bidirectional moisture control requires engineered fiber structures and specialized treatments that create preferential pathways for moisture movement. The capillary action within the fabric structure determines how effectively moisture moves from high-concentration areas to evaporation zones.

Advanced lining fabric incorporates gradient structures that optimize moisture transport efficiency. Multi-layer constructions may feature different fiber types or treatments on each side to create directional moisture movement. Some systems include phase-change materials that absorb and release thermal energy to maintain comfortable skin temperatures. These sophisticated approaches transform simple lining fabric into active comfort management systems.

Durability and Maintenance Considerations

Industrial lining fabric must withstand rigorous use conditions while maintaining performance characteristics throughout its service life. Abrasion resistance becomes critical in high-movement applications where the lining experiences constant friction. The fabric structure must resist pilling, tearing, and dimensional changes that could affect fit or comfort. Chemical resistance ensures that cleaning processes and workplace exposures don't degrade the lining properties.

Maintenance requirements significantly impact the practical value of lining fabric in industrial applications. The material must survive commercial laundering processes while retaining moisture management, antimicrobial, and other specialized properties. Some applications require dry-cleaning compatibility or specific washing protocols to maintain performance. The long-term cost-effectiveness depends on how well the lining fabric maintains its properties through multiple cleaning and use cycles.

Selection Criteria and Best Practices

Environmental Factor Assessment

Selecting appropriate lining fabric requires comprehensive analysis of the intended use environment. Temperature extremes, humidity levels, chemical exposures, and physical activity levels all influence material requirements. High-temperature environments may require heat-resistant fibers or reflective treatments, while cold conditions might favor insulating properties. Chemical exposures necessitate compatibility testing to ensure the lining fabric won't degrade or compromise protective functions.

Activity level assessment determines the required moisture management capacity and breathability characteristics. Sedentary work environments may prioritize comfort and basic moisture control, while high-activity applications demand rapid moisture transport and enhanced breathability. The physical demands of the work environment also influence abrasion resistance and durability requirements for the lining fabric system.

Integration with Outer Shell Materials

Successful lining fabric implementation requires careful consideration of compatibility with outer shell materials. Thermal expansion characteristics must match to prevent stress concentrations or fit problems during temperature changes. Moisture vapor transmission rates should complement each other to create effective moisture management systems. Some combinations may require additional treatments or barrier layers to achieve optimal performance.

Attachment methods and seam construction significantly impact the overall garment performance. The lining fabric must accommodate the flexibility and movement requirements of the outer shell while maintaining proper positioning. Innovative attachment systems may use strategic tacking points or zoned attachment to optimize both comfort and performance. The integration approach often determines whether the lining fabric enhances or compromises the overall garment functionality.

Innovation and Future Developments

Smart Textile Integration

Emerging technologies are transforming lining fabric from passive comfort layers into active performance systems. Smart textiles incorporate sensors, conductive fibers, or phase-change materials that respond to environmental conditions or wearer physiology. These advanced systems can provide real-time feedback about exposure conditions, physiological stress, or equipment performance. The integration of electronic components requires specialized lining fabric that accommodates wiring while maintaining flexibility and comfort.

Future developments may include self-regulating moisture management systems that automatically adjust permeability based on activity levels. Adaptive insulation properties could respond to ambient temperatures to maintain optimal thermal comfort. Antimicrobial systems might actively eliminate bacteria and odors rather than simply inhibiting growth. These innovations will continue expanding the role of lining fabric in industrial and technical applications.

Sustainability Considerations

Environmental sustainability increasingly influences lining fabric selection and development. Recycled fiber content, biodegradable treatments, and reduced environmental impact manufacturing processes are becoming standard requirements. Life cycle assessments consider the total environmental impact from raw material production through end-of-life disposal. Sustainable lining fabric options must maintain performance standards while reducing environmental footprint.

Circular economy principles are driving innovations in lining fabric recyclability and reusability. Design for disassembly enables separation of different fabric layers for recycling streams. Chemical recycling technologies may allow high-performance synthetic fibers to be recovered and reprocessed into new lining fabric. These approaches support sustainability goals while maintaining the technical performance required for industrial applications.

FAQ

What makes lining fabric essential for industrial garments

Lining fabric serves multiple critical functions in industrial garments including moisture management, temperature regulation, and comfort enhancement. It provides a smooth interface between protective outer shells and the wearer's skin, reducing friction and improving mobility. In many applications, the lining fabric also contributes to the overall protective properties of the garment system through specialized treatments or barrier functions.

How does lining fabric affect garment durability

Quality lining fabric significantly extends garment life by reducing stress on outer shell materials and providing additional structural support. It helps maintain garment shape and fit over time while protecting interior seams from wear. The lining also reduces the need for frequent washing of the entire garment by managing moisture and odors, which helps preserve the protective properties of specialized outer materials.

Can lining fabric be retrofitted to existing garments

While technically possible, retrofitting lining fabric to existing garments is generally not cost-effective or recommended for industrial applications. The integration requires significant modification of the garment construction and may compromise existing protective features. New garment construction allows for proper integration of lining systems with appropriate attachment methods and performance optimization.

What maintenance requirements apply to technical lining fabrics

Technical lining fabrics often require specific cleaning procedures to maintain their performance properties. Some materials need gentle washing cycles, specific temperature limits, or avoid certain detergents that could affect specialized treatments. Regular inspection for wear, damage, or performance degradation ensures the lining continues providing intended benefits throughout the garment's service life.