แนวทางการดูแลที่สำคัญสำหรับผ้าทอเคลือบเกรดการแพทย์

ผ้าทอเคลือบเกรดการแพทย์มีบทบาทสำคัญในสถานที่ให้บริการด้านสาธารณสุข ตั้งแต่ผ้าคลุมสำหรับการผ่าตัดไปจนถึงอุปกรณ์ป้องกัน การเข้าใจเทคนิคการบำรุงรักษาที่เหมาะสมจะช่วยให้วัสดุพิเศษเหล่านี้คงคุณสมบัติในการป้องกันไว้ได้ และยืดอายุการใช้งานออกไป สถานพยาบาลลงทุนจำนวนมากในการซื้อผ้าทอเคลือบคุณภาพสูง การดูแลและบำรุงรักษาอย่างเหมาะสมจึงไม่ใช่เพียงแค่เรื่องอายุการใช้งาน แต่ยังเกี่ยวข้องกับประสิทธิภาพทางเศรษฐกิจและความปลอดภัยของผู้ป่วยอีกด้วย

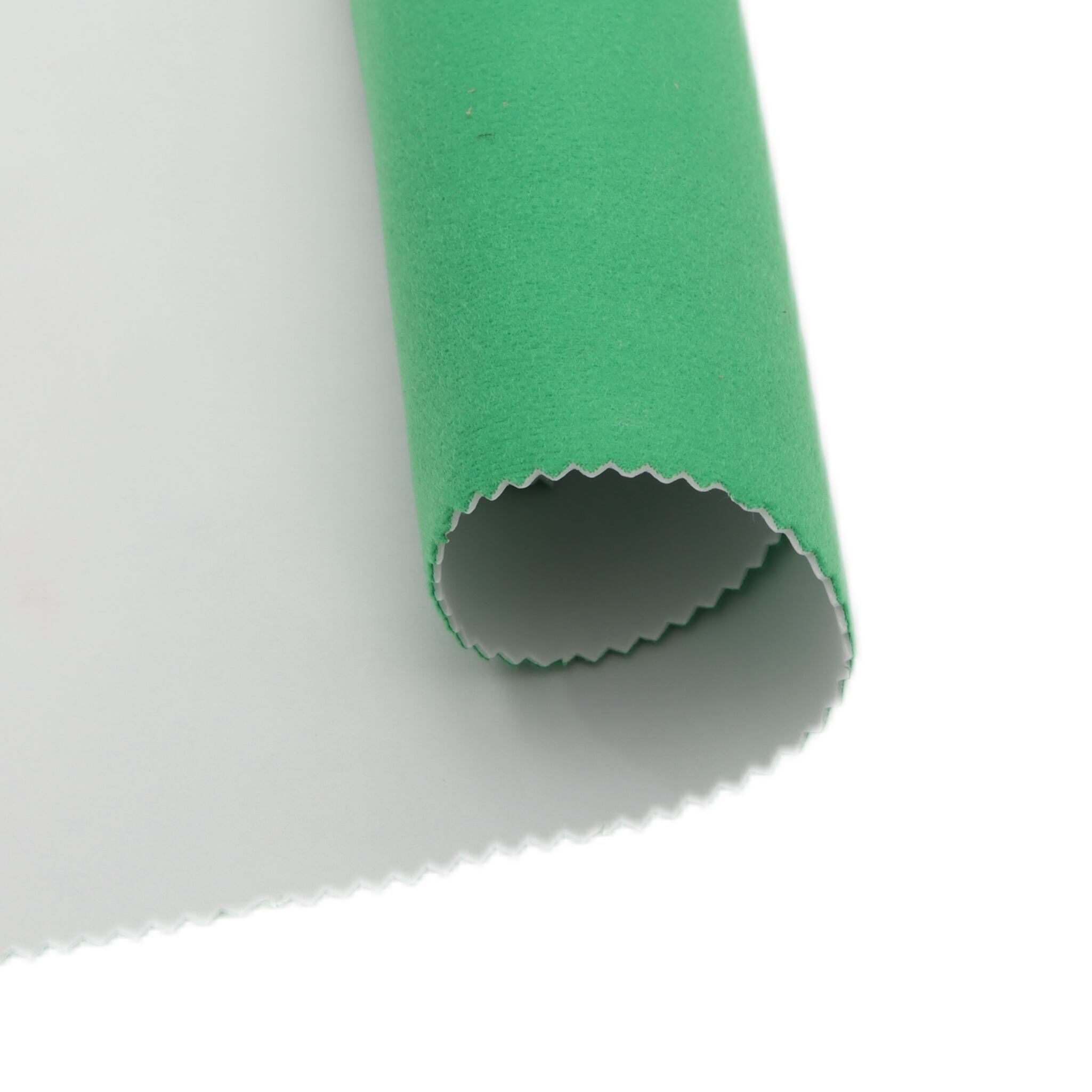

การสร้างที่พิเศษของผ้าที่ผูกพันกัน ผสมผสานหลายชั้นผ่านการผูกผูกกันทางความร้อนหรือการผูกติดกัน ทําให้มีคุณสมบัติป้องกันที่เหนือกว่าที่จําเป็นสําหรับการใช้งานทางการแพทย์ อย่างไรก็ตาม คุณสมบัติเดียวกันนี้ ต้องการโปรโตคอลการบํารุงรักษาพิเศษ เพื่อรักษาความสมบูรณ์แบบของพวกเขา ลองมาดูกลยุทธ์การบํารุงรักษาที่ครบถ้วน ที่สถานพยาบาลสามารถนําไปใช้ เพื่อให้อายุการใช้งานของผ้าที่ผูกติดกันได้สูงที่สุด

ขั้นตอนการทำความสะอาดและการฆ่าเชื้อ

ข้อกำหนดการทำความสะอาดรายวัน

การ ทําความสะอาดผ้าที่ผูกเข้ากันอย่างถูกต้อง เริ่มต้นจากการเข้าใจความต้องการเฉพาะของวัสดุ สถานที่การแพทย์ต้องการการกําจัดโรคอย่างเข้มงวด โดยไม่เสียสละความสมบูรณ์แบบของผ้า ใช้ยาฆ่าเชื้อระดับโรงพยาบาล ที่ได้รับอนุมัติโดยเฉพาะสําหรับผ้าที่ผูกกัน ให้แน่ใจว่ามันไม่حتويถึงสารเคมีที่รุนแรง ที่อาจทําลายสารผูกกัน

การจัดทำตารางการทำความสะอาดอย่างเป็นระบบช่วยให้สามารถรักษามาตรฐานด้านสุขอนามัยได้อย่างสม่ำเสมอ เริ่มต้นด้วยการกำจัดเศษสิ่งสกปรกที่มองเห็นได้โดยใช้ผ้าไม่ติดขนลิน ตามด้วยการใช้สารละลายทำความสะอาดที่เหมาะสม โดยตลอดเวลาให้ทำงานจากพื้นที่สะอาดไปยังพื้นที่ปนเปื้อนเพื่อป้องกันการปนเปื้อนข้าม ควรให้เวลารอให้แห้งอย่างเพียงพอในแต่ละขั้นตอนการทำความสะอาด เพื่อป้องกันการสะสมของความชื้นภายในชั้นผ้า

ขั้นตอนการทำความสะอาดอย่างลึกซึ้ง

การล้างทำความสะอาดผ้าที่ติดกาวเป็นประจำต้องใช้ความละเอียดถี่ถ้วนมากขึ้น แต่ยังคงคุณสมบัติการป้องกันของวัสดุไว้ได้ ควรจัดตารางการทำความสะอาดอย่างละเอียดในช่วงเวลาที่มีกิจกรรมน้อย เพื่อให้แน่ใจว่าได้รับการดูแลรักษาอย่างทั่วถึง ใช้อุปกรณ์ทำความสะอาดเฉพาะทางที่ออกแบบมาสำหรับเนื้อผ้าทางการแพทย์ โดยรักษาระดับแรงดันและอุณหภูมิให้คงที่ตลอดกระบวนการ

บริการทําความสะอาดมืออาชีพที่มีความเชี่ยวชาญในเรื่องผ้าเพื่อการแพทย์ สามารถให้การรักษาที่เชี่ยวชาญมากกว่าการบํารุงรักษาปกติ บริการเหล่านี้มักใช้เทคนิคที่ทันสมัย เช่น การทําความสะอาดด้วยเสียงฉาย หรือการแปรรูปโดยใช้สภาพแวดล้อมที่ควบคุม เพื่อรักษามาตรฐานความสะอาดสูงสุดในขณะที่ปกป้องโครงสร้างที่ผูกพันของผ้า

แนวทางปฏิบัติที่ดีที่สุดเกี่ยวกับการเก็บรักษาและการจัดการ

สภาพการเก็บรักษาที่เหมาะสมที่สุด

การสร้างสภาพการเก็บรักษาที่เหมาะสม มีผลต่ออายุยาวของผ้าที่ผูก รักษาสภาพแวดล้อมที่ควบคุมได้ โดยมีอุณหภูมิระหว่าง 60-75°F (15-24°C) และความชื้นสัมพัทธ์ระหว่าง 30-50% สภาพเหล่านี้ช่วยป้องกันการทําลายของสารผูกและรักษาความสมบูรณ์แบบของผ้า

ใช้ระบบเก็บของที่เหมาะสม เพื่อป้องกันการบดหรือบดความเครียดบนวัสดุ ใช้ ที่เก็บไว้ ที่แขวน เมื่อเป็นไปได้ หรือม้วนชิ้นใหญ่ๆ แทนที่จะพับมัน ให้แน่ใจว่าพื้นที่เก็บของยังสะอาด แห้ง และคุ้มกันจากแสงแดดตรง ซึ่งอาจทําให้สารผูกรัดเสื่อมลงตามเวลา

แนวทาง การ ใช้ งาน ที่ ถูก ต้อง

การฝึกพนักงานในวิธีการจัดการที่ถูกต้อง ช่วยลดการสกัดและการขาดทรัพย์ของสิ่งของผ้าที่ผูก กําหนดระเบียบที่ชัดเจน สําหรับการยก ย้าย และใช้วัสดุเหล่านี้ ส่งเสริมการใช้มือที่สะอาดแห้ง หรือถุงมือที่เหมาะสม เมื่อมือกับผ้า เพื่อป้องกันการถ่ายน้ํามันและความชื้น

ใช้ระบบหมุนเพื่อให้แน่ใจว่าสวมใส่ได้เสมอไปในทุกชิ้น โดยเฉพาะสําหรับชิ้นที่ใช้บ่อย การตรวจสอบเป็นประจําระหว่างการจัดการ ช่วยระบุสัญญาณของการเสียหายหรือเสียหายในช่วงแรก

กลยุทธ์การบำรุงรักษาเชิงป้องกัน

ข้อกำหนดในการตรวจสอบเป็นประจำ

การจัดทําตารางการตรวจสอบอย่างเป็นระบบ ช่วยระบุปัญหาที่เป็นไปได้ ก่อนที่มันจะกลายเป็นปัญหาใหญ่ ฝึกพนักงานให้จําปะรอยการสวม เช่น การล้างแผ่นผิว, การผูกผูกที่อ่อนแอ หรือการเสียหายของผิว บันทึกการตรวจสอบและข้อพบทั้งหมด เพื่อติดตามรูปแบบและคาดการณ์ความต้องการในการบํารุงรักษา

ใช้รายการตรวจสอบที่มาตรฐาน ซึ่งครอบคลุมทุกด้านสําคัญของสภาพของผ้าที่ผูก รวมถึงการประเมินความสมบูรณ์แบบของเย็บ, ความสม่ําเสมอของพื้นผิว, และผลงานของวัสดุโดยรวม การติดตามเป็นประจํา ช่วยรักษามาตรฐานคุณภาพ และรับประกันการเปลี่ยนในเวลาที่ถูกต้องเมื่อจําเป็น

เอกสารการบำรุงรักษา

จัดบันทึกรายละเอียดเกี่ยวกับกิจกรรมบํารุงรักษาทั้งหมดที่ทํากับสินค้าผ้าที่ผูก รายงาน วัน ที่ ทํา ความ สะอาด วิธี การ ที่ ใช้ และ การ ซ่อม หรือ การ ปก ป้อง ที่ พิเศษ ใด ๆ ที่ ใช้. เอกสารนี้ช่วยติดตามวงจรชีวิตของวัสดุและปรับปรุงตารางบํารุงรักษาตามรูปแบบการใช้จริง

การนําระบบติดตามดิจิตอลมาใช้เพื่อทําให้เอกสารการบํารุงรักษาและผลิตเตือนแบบอัตโนมัติสําหรับงานบํารุงรักษาตามกําหนด ระบบนี้สามารถช่วยให้การดูแลที่คงที่ และยังให้ข้อมูลที่มีค่าสําหรับการวางแผนการจัดซื้อและบํารุงรักษาในอนาคต

การ พิจารณา เรื่อง การ ดูแล คน ที่ มี โรค ยาวนาน

การจัดการผลกระทบต่อสิ่งแวดล้อม

พิจารณาถึงปัจจัยทางสิ่งแวดล้อมที่อาจส่งผลต่อสมรรถนะของผ้าทอแบบบอนด์ด์ในระยะยาว ควบคุมการสัมผัสแสงสว่างที่จ้าเกินไป อุณหภูมิสุดขั้ว และสารเคมีที่อาจทำให้ความสมบูรณ์ของวัสดุเสียหาย ติดตั้งระบบกรองอากาศที่เหมาะสมในพื้นที่จัดเก็บและพื้นที่ผลิต เพื่อลดการสัมผัสมลพิษทางอากาศ

พัฒนากลยุทธ์เพื่อปกป้องผ้าทอแบบบอนด์ด์จากตัวกระตุ้นที่เป็นอันตรายต่อสิ่งแวดล้อมในระหว่างการใช้งาน อาจรวมถึงการใช้ผ้าคลุมป้องกันในระหว่างการขนส่ง หรือปฏิบัติตามขั้นตอนการจัดการเฉพาะในระหว่างกระบวนการที่มีความเสี่ยงสูง

มาตรการรับประกันคุณภาพ

จัดตั้งโปรแกรมการประกันคุณภาพที่ครอบคลุม เพื่อตรวจสอบสมรรถนะของผลิตภัณฑ์ผ้าทอแบบบอนด์ด์อย่างต่อเนื่อง การทดสอบเป็นประจำเกี่ยวกับคุณสมบัติการกันน้ำ ความแข็งแรง และความทนทาน จะช่วยให้มั่นใจได้ว่าวัสดุยังคงเป็นไปตามมาตรฐานที่กำหนด ร่วมมือกับผู้จัดหาและห้องปฏิบัติการทดสอบ เพื่อดำเนินการประเมินความสมบูรณ์ของวัสดุเป็นระยะ

ใช้ระบบตอบรับข้อมูลที่ช่วยให้ผู้ใช้งานปลายทางสามารถรายงานปัญหาหรือข้อสังเกตเกี่ยวกับประสิทธิภาพของวัสดุได้ ข้อมูลนี้สามารถช่วยระบุแนวโน้มและปรับปรุงขั้นตอนการบำรุงรักษาให้เหมาะสม เพื่อยืดอายุการใช้งานวัสดุ

คำถามที่พบบ่อย

ผ้าที่ผ่านการบอนด์ควรได้รับการตรวจสอบความเสียหายบ่อยแค่ไหน

ผ้าที่บอนด์สำหรับใช้ในทางการแพทย์ควรได้รับการตรวจสอบด้วยสายตาทุกครั้งก่อนใช้งาน และควรได้รับการประเมินโดยผู้เชี่ยวชาญอย่างละเอียดอย่างน้อยทุกสามเดือน สำหรับสิ่งของที่ใช้งานบ่อย อาจต้องการการตรวจสอบบ่อยขึ้น เช่น รายสัปดาห์หรือรายเดือน ขึ้นอยู่กับรูปแบบการใช้งานและสภาพแวดล้อมที่สัมผัส

สัญญาณที่บ่งชี้ว่าผ้าที่บอนด์จำเป็นต้องเปลี่ยนมีอะไรบ้าง

ตัวชี้วัดหลัก ได้แก่ การแยกชั้นเห็นได้ด้วยตา ความเสียหายหรือการหลุดลอกของรอยบอนด์ ความสึกหรอที่ผิวหน้าอย่างชัดเจน ประสิทธิภาพการป้องกันที่ลดลง หรือคุณสมบัติการป้องกันของวัสดุที่ถดถอย การทดสอบคุณสมบัติการป้องกันของวัสดุเป็นประจำจะช่วยให้ทราบว่าควรเปลี่ยนวัสดุเมื่อใด

สามารถซ่อมแซมผ้าที่บอนด์ที่เกิดความเสียหายได้หรือไม่

ความเสียหายเล็กน้อยต่อผ้าที่ถูกบอนด์อาจสามารถซ่อมแซมได้โดยใช้เทคนิคเฉพาะ แต่ทั้งนี้ขึ้นอยู่กับระดับและตำแหน่งของความเสียหายเป็นหลัก โดยทั่วไป หากคุณสมบัติการกันซึมหรือความสมบูรณ์ทางโครงสร้างถูกกระทบ การแนะนำคือให้เปลี่ยนใหม่เพื่อรักษาความปลอดภัย ควรปรึกษาผู้ผลิตหรือผู้เชี่ยวชาญที่ได้รับการรับรองเพื่อขอคำแนะนำเสมอ