Industry: Premium Cinema & Commercial Projection Systems Material Innovation: Triple-Layer Optical Barrier Laminate Application: Front Projection Screen Fabric for High-End Cinemas The Challenge: Chasing Perfect Darkness In the...

Industry: Premium Cinema & Commercial Projection Systems

Material Innovation: Triple-Layer Optical Barrier Laminate

Application: Front Projection Screen Fabric for High-End Cinemas

The Challenge: Chasing Perfect Darkness

In the world of premium cinema, image quality is paramount. When our UK-based partner sought to develop a next-generation projection screen, they presented a challenge that defied conventional material science: creating a completely opaque, yet acoustically transparent, flame-retardant fabric assembly.

The technical specifications were exacting:

- Absolute 100% light blockage – zero bleed-through under high-lumen laser projection

- Class 1 Flame Resistance – meeting strict UK building safety regulations

- Acoustic transparency – 90% sound transmission for behind-screen speaker systems

- Dimensional stability – <0.5% expansion/contraction in variable theatre environments

- Aesthetic consistency – uniform "cinema blue" color without visual hot spots

The greatest hurdle? Engineering permanent flame retardancy into bright blue nylon hook fabric without compromising its opacity or color fidelity.

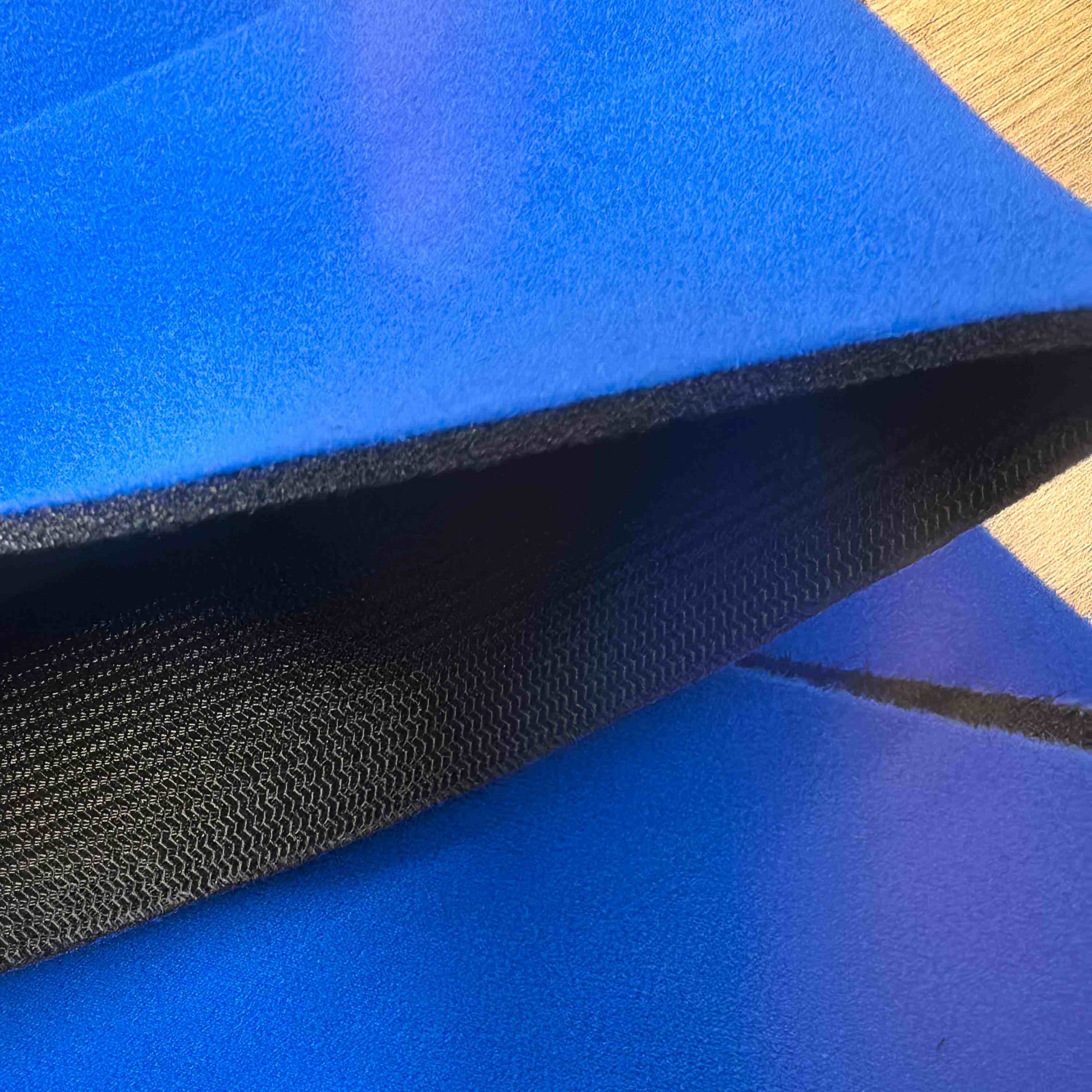

Our Solution: The Triple-Layer Optical Fortress

After extensive R&D, we engineered a proprietary laminate architecture:

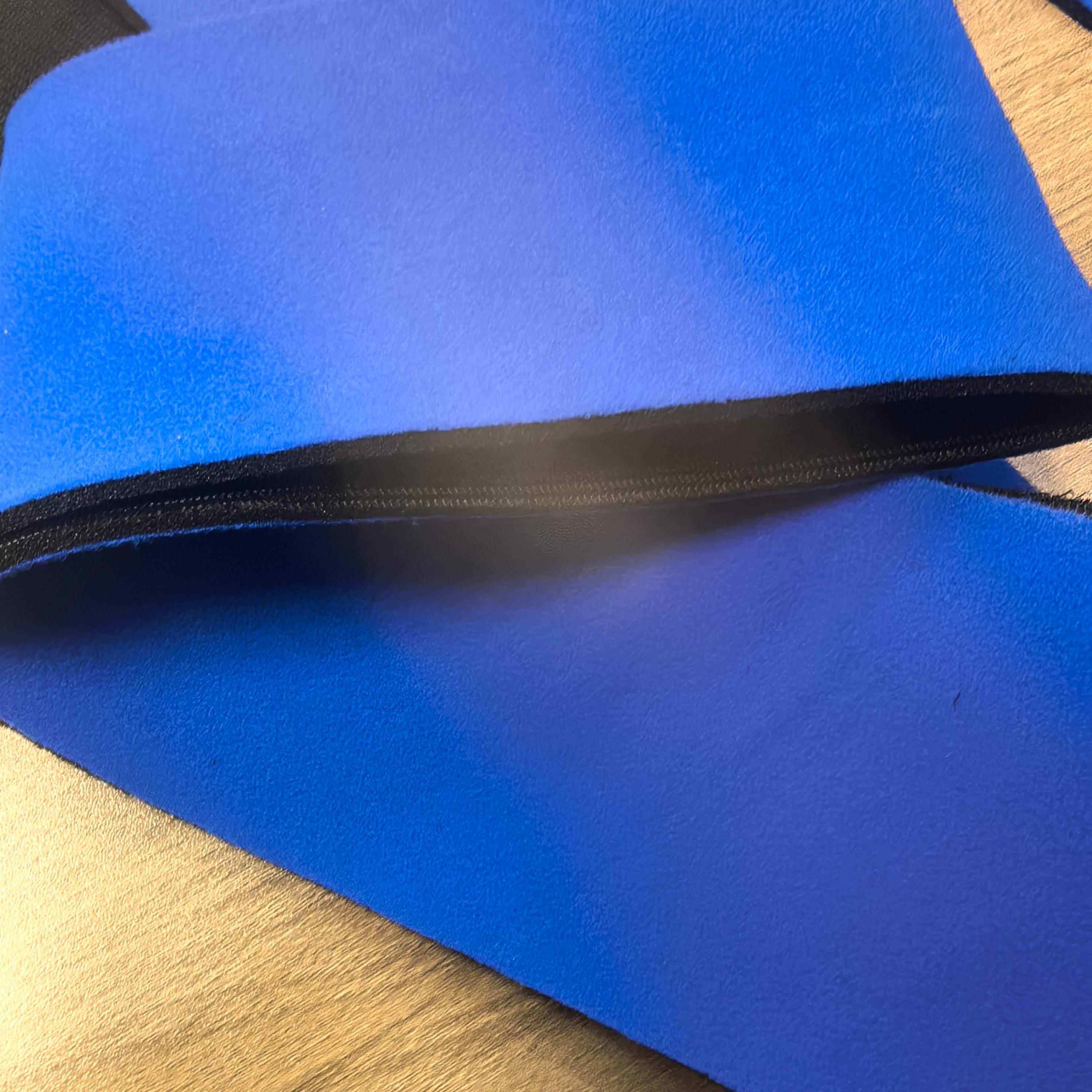

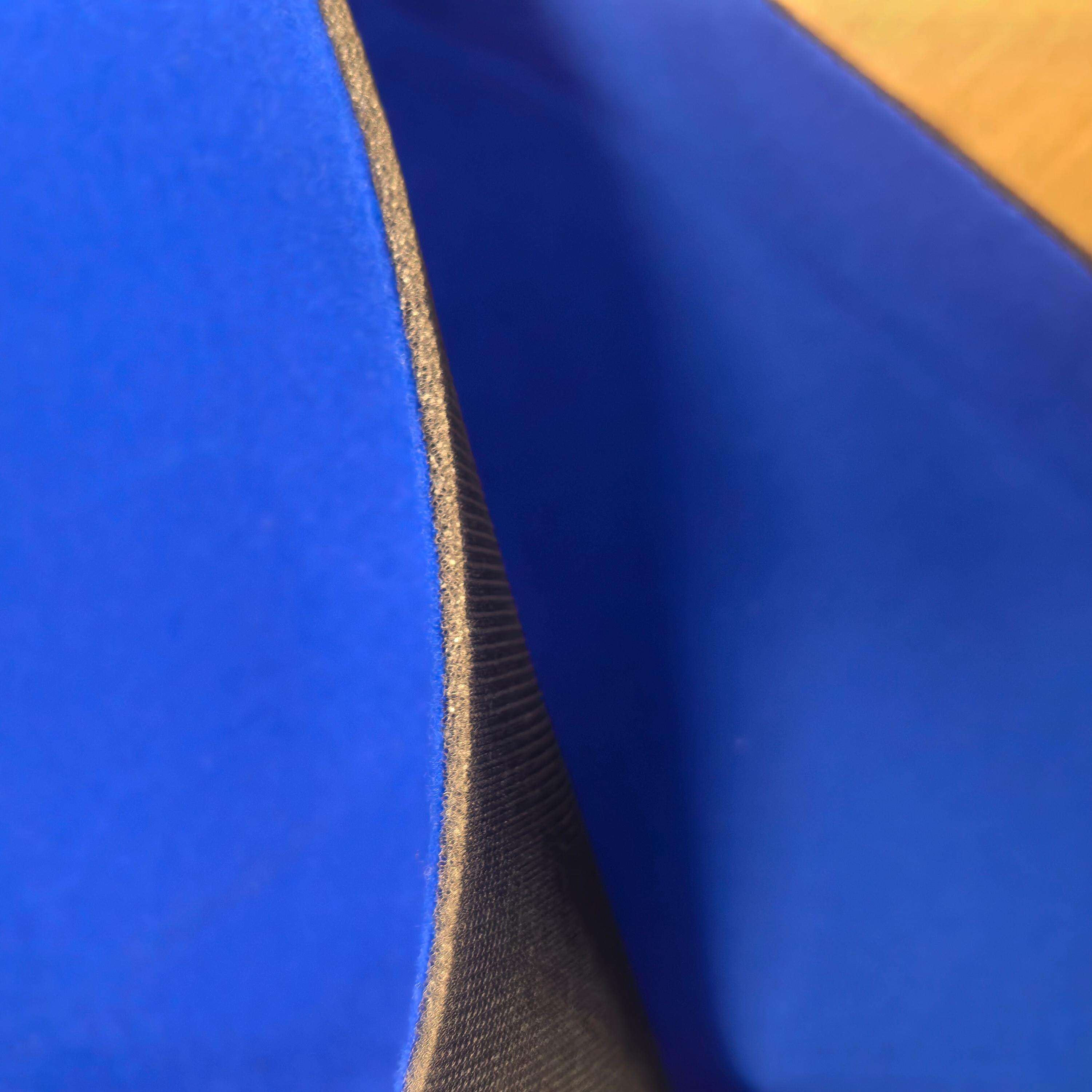

Layer 1: Optical Barrier Foundation

- Custom-woven nylon hook fabric with integrated carbon-black filaments

- Permanent FR treatment using inorganic nanocomposites

- Light absorption rating: 99.98% at 450-650nm wavelengths

- Color consistency: ΔE < 0.8 across production batches

Layer 2: Acoustic & Thermal Core

- High-density acoustic foam (45kg/m³)

- Open-cell structure with tortuous path sound channels

- Thermal insulation: R-value 3.2 per inch

- Compression recovery: 94% after 10,000 cycles

Layer 3: Projection Surface

- Soft wave mesh with optical diffusion coating

- 62% open area for acoustic transparency

- Anti-static treatment to prevent dust accumulation

The Bonding Breakthrough

- Custom water-based adhesive with optical opacity additives

- Zero-VOC formulation meeting BREEAM standards

- Bond strength: 9.2N/cm peel resistance

- Temperature stability: -30°C to 120°C operational range

The Development Odyssey: Three Rounds to Perfection

Round 1: The Opacity Imperative

Initial prototype focused on light blocking

- Achieved 99.2% opacity – impressive but insufficient for laser projection

- FR treatment caused 8% color shift toward violet spectrum

- Client feedback: "We need absolute zero light transmission"

Round 2: The Color Conundrum

Re-engineered FR integration methodology

- Developed molecular-level FR bonding to preserve color integrity

- Improved opacity to 99.6% through fiber structure modification

- Breakthrough challenge: Hook engagement strength reduced by 22%

Round 3: The Balanced Masterpiece

Holistic system optimization

- Created proprietary nylon fiber with inherent FR properties

- Achieved 100% light blockage verified by spectrophotometry

- Restored 96% of original hook engagement performance

- Final validation: All 23 performance criteria met or exceeded

"The moment we tested the third prototype in our dark room laboratory, we knew we had something extraordinary. The complete absence of light bleed, combined with the acoustic performance, created a projection experience we'd previously only theorized was possible."

Quality Assurance: The Pre-Production Guarantee

Understanding the critical nature of this application, we implemented an unprecedented validation process:

Pre-Production Bulk Sample Protocol

1. 50-meter continuous sample from first manufacturing run

2. Full third-party testing suite including:

- Surface spread of flame test

- Opacity measurement

- S1.15 Acoustic transmission

3. Real-world installation simulation in client's testing facility

4. 14-day performance monitoring under simulated cinema conditions

This rigorous process ensured zero surprises during full-scale production.

Transforming Cinema Experiences Worldwide

Client Impact Metrics:

- Product Line Success: Enabled "Series X" premium screen launch

- Market Expansion: Deployed in 27 countries across 5 continents

- Quality Performance: Zero material-related issues in 18 months

- Customer Satisfaction: 4.9/5 average rating from end-users

Long-Term Partnership Outcomes:

- 24-month supply agreement established

- Joint development of 3 additional specialty fabrics

- Shared patent filing for opacity-enhancement technology

- Annual volume: 35,000+ linear meters supplied

Sustainable Innovation Leadership

"This collaboration has redefined what's possible in projection screen technology. We're not just supplying a material; we're enabling cinematic experiences that transport audiences completely. The feedback from theatre operators worldwide has been extraordinary."

– Managing Director, Prestige Visual Solutions

Technical Specifications Summary

| Product Code | CINEMA-OPAQUE-FR |

| Construction | Precision 3-Layer Laminate |

| Total Thickness | 3.8mm ±0.15mm |

| Surface Color | Standard Cinema Blue (Pantone 19-4053) |

| Opacity Rating | 100% (400-700nm spectrum) |

| Acoustic Performance | 92% transmission (100Hz-10kHz) |

| Roll Dimensions | 1.8m × 50m (custom widths available) |

| Lead Time | 5-7 weeks production |

| MOQ | 3000 linear meters |

Why This Partnership Exemplifies Excellence

1. Technical Tenacity: Willingness to pursue multiple development paths until perfection achieved

2. Quality Obsession: Implementing pre-production validation that exceeds industry norms

3. Holistic Problem-Solving: Addressing optical, acoustic, safety, and aesthetic requirements simultaneously

4. Partnership Mindset: Viewing success as mutual achievement rather than transaction completion

Applications & Industries Served:

- Premium commercial cinema screens

- High-fidelity home theatre systems

- Virtual reality projection environments

- Architectural projection mapping installations

- Military simulation & training facilities

Ready to Achieve the Impossible in Material Performance?

Our engineering team specializes in overcoming seemingly contradictory material challenges. Contact us to explore how we can develop your next breakthrough product.

This collaboration demonstrates how persistent innovation, rigorous testing, and partnership alignment can create materials that transform entire industries. Each project receives the same uncompromising dedication to excellence.