Das Verständnis der Revolution bei Komfort- und Schutzmaterialien

Die Weiterentwicklung von Polstermaterialien hat verändert, wie wir Komfort und Sicherheit in unserer Alltagsausrüstung erleben. An vorderster Front dieser Innovation steht das Mesh-Schaumstoffgewebe, ein bemerkenswertes Material, das die Art und Weise, wie Hersteller Polsterungen in Rucksäcken und Schutzausrüstungen gestalten, revolutioniert hat. Dieses vielseitige Material kombiniert die Atmungsaktivität von Mesh mit den dämpfenden Eigenschaften von Schaumstoff und schafft so eine optimale Lösung für verschiedene Anwendungen.

Moderne Abenteurer, Athleten und Alltagsnutzer verlangen zunehmend nach Ausrüstung, die nicht nur schützt, sondern auch den Komfort bei längerer Nutzung verbessert. Mesh-Schaumstoffgewebe erfüllt diese Anforderung, indem es eine einzigartige Kombination aus Haltbarkeit, Belüftung und Stoßschutz bietet, die herkömmliche Materialien einfach nicht erreichen können.

Technische Zusammensetzung und Eigenschaften

Materialaufbau und Design

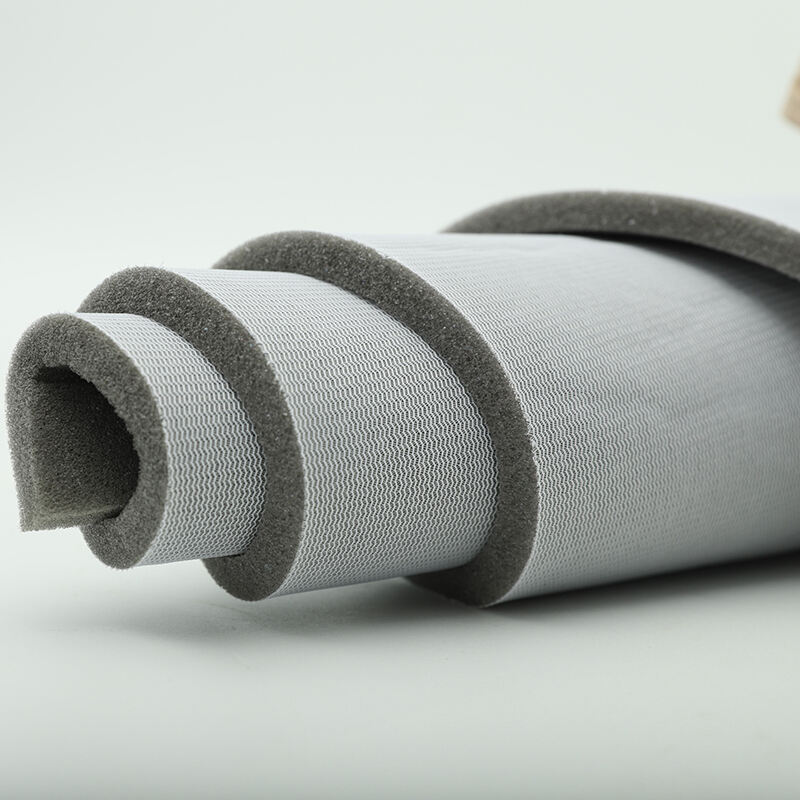

Mesh-Schaumstoffgewebe weist einen komplexen Aufbau auf, der mehrere Schichten kombiniert, um seine überlegene Leistungsfähigkeit zu erreichen. Die Außenschicht besteht aus einem strapazierfähigen Maschenmaterial, das typischerweise aus Polyester oder Nylon hergestellt ist und einen freien Luftdurchfluss durch das Gewebe ermöglicht. Diese Maschenschicht ist mit einem speziellen Schaumkern verbunden, der Polsterung und Stoßabsorption bietet. Das resultierende Verbundmaterial bietet außergewöhnliche Atmungsaktivität, behält dabei aber seine schützenden Eigenschaften bei.

Der Schaumkern selbst kann in Dichte und Dicke variieren, wodurch Hersteller die Materialeigenschaften für spezifische Anwendungen anpassen können. Diese Anpassungsfähigkeit macht Mesh-Schaumstoffgewebe zu einer idealen Wahl sowohl für leichte Rucksackpolsterung als auch für robuste Schutzausrüstung.

Leistungsmerkmale

Die einzigartigen Eigenschaften von Mesh-Schaumstoffgewebe machen es besonders gut geeignet für Polsteranwendungen. Seine offenzellige Struktur fördert die Luftzirkulation und verhindert Hitzestau sowie Feuchtigkeitsansammlung, die zu Unbehagen führen können. Das Material zeichnet sich durch hervorragende Rückstellfähigkeit aus und behält seine Form sowie schützenden Eigenschaften auch nach längerer Kompression bei.

Darüber hinaus weist Mesh-Schaumstoffgewebe im Vergleich zu herkömmlichen Polstermaterialien eine überlegene Reißfestigkeit und Haltbarkeit auf. Seine integrierte Struktur verteilt Kräfte über einen größeren Bereich, reduziert Druckstellen und verbessert so den Gesamtkomfort für den Benutzer.

Vorteile für Rucksackanwendungen

Verbesserter Komfort beim Tragen über längere Zeiträume

Wenn als Polsterung in Rucksäcken verwendet, schafft das Netz-Schaumstoffgewebe eine optimale Verbindung zwischen dem Rucksack und dem Körper des Trägers. Die atmungsaktive Beschaffenheit des Materials verhindert das unangenehme Schwitzen, das oft mit herkömmlicher Schaumstoffpolsterung einhergeht, während seine dämpfenden Eigenschaften das Gewicht des Rucksacks effektiv auf den Rücken und die Schultern verteilen.

Die Fähigkeit des Materials, seine Form beizubehalten, sorgt für gleichbleibende Leistung bei langen Wanderungen oder täglichen Pendelstrecken. Selbst beim Tragen schwerer Lasten über längere Zeiträume hinweg verspüren Nutzer weniger Ermüdung und erhöhten Komfort.

Langlebigkeit und Wartung

Rucksäcke mit Polsterung aus Netz-Schaumstoffgewebe zeichnen sich durch außergewöhnliche Langlebigkeit aus. Das Material widersteht bleibender Kompression, d. h., es kehrt auch nach längerer Zusammendrückung wieder in seine ursprüngliche Form zurück. Diese Widerstandsfähigkeit führt zu einer konstanten Leistung über die gesamte Lebensdauer des Produkts.

Die Wartung ist unkompliziert, da die Netzstruktur eine einfache Reinigung und schnelles Trocknen ermöglicht. Die feuchtigkeitsbeständigen Eigenschaften des Materials helfen, das Wachstum von Bakterien und Gerüchen zu verhindern, was zu einer besseren Hygiene und einer längeren Produktlebensdauer beiträgt.

Vorteile beim Helmschutz

Schlagfestigkeit und Sicherheitsmerkmale

In Helmanwendungen bietet das Netzschaumstoffgewebe einen entscheidenden Schutz vor Stößen, während es gleichzeitig optimalen Komfort gewährleistet. Die Fähigkeit des Materials, Kräfte zu absorbieren und zu verteilen, macht es zu einer hervorragenden Wahl für Schutzhelme bei verschiedenen Tätigkeiten, vom Radfahren bis zur Baustelle. Die mehrschichtige Struktur des Netzschaumstoffgewebes schafft mehrere Schutzzonen und verbessert so die Fähigkeit des Helms, sowohl vor direkten als auch vor seitlichen Aufprallen zu schützen.

Moderne Helmdesigns, die Mesh-Schaumstoffgewebe verwenden, übertreffen oft die Sicherheitsstandards, bleiben dabei jedoch erstaunlich leicht. Die effizienten Aufprallschutzeigenschaften des Materials ermöglichen dünnere Polsterprofile, ohne die Schutzniveaus zu beeinträchtigen.

Belüftungs- und Komfortlösungen

Einer der bedeutendsten Vorteile der Verwendung von Mesh-Schaumstoffgewebe in der Helm-Polsterung ist die überlegene Belüftung. Die offene Struktur des Materials fördert einen kontinuierlichen Luftstrom, hilft dabei, die Temperatur zu regulieren und Überhitzung während intensiver Aktivitäten oder bei Nutzung bei warmem Wetter zu vermeiden.

Die feuchtigkeitsableitenden Eigenschaften des Gewebes arbeiten zusammen mit den Belüftungseigenschaften, um den Kopf des Trägers trocken und komfortabel zu halten. Diese Kombination aus Vorteilen macht Mesh-Schaumstoffgewebe besonders wertvoll in Hochleistungsanwendungen, bei denen Komfort und Sicherheit Hand in Hand gehen müssen.

Umwelt- und Nachhaltigkeitsaspekte

Fertigungsinnovationen

Moderne Herstellungsverfahren für Mesh-Schaumstoffgewebe konzentrieren sich zunehmend auf Nachhaltigkeit. Fortschrittliche Produktionstechniken minimieren Abfall und senken den Energieverbrauch, während einige Hersteller bereits recycelte Materialien in ihre Mesh-Schaumstoffgewebe-Produkte integrieren. Diese Innovationen tragen dazu bei, die Umweltbelastung durch die Herstellung von Schutzausrüstungen zu verringern.

Die Langlebigkeit von Mesh-Schaumstoffgewebe trägt ebenfalls zur Nachhaltigkeit bei, indem sie die Produktlebensdauer verlängert und die Notwendigkeit häufiger Ersetzungen reduziert. Diese Langlebigkeit hilft, den Gesamtverbrauch an Ressourcen und die Abfallmenge zu verringern.

Künftige Entwicklungen

Die Forschung setzt sich mit biologisch abbaubaren Alternativen und noch nachhaltigeren Produktionsmethoden für Mesh-Schaumstoffgewebe fort. Hersteller erforschen bio-basierte Materialien und geschlossene Recyclingkreisläufe, um das ökologische Profil des Materials weiter zu verbessern. Diese Entwicklungen versprechen, Mesh-Schaumstoffgewebe für umweltbewusste Verbraucher und Hersteller alike zu einer noch attraktiveren Option zu machen.

Häufig gestellte Fragen

Wie lange hält die Polsterung aus Mesh-Schaumstoffgewebe in der Regel?

Bei sachgemäßer Pflege und regelmäßiger Nutzung kann die Polsterung aus Mesh-Schaumstoffgewebe ihre Leistungseigenschaften über mehrere Jahre hinweg beibehalten. Die Elastizität und Erholungsfähigkeit des Materials tragen zur langfristigen Haltbarkeit bei, wobei die genaue Lebensdauer von der Beanspruchungsintensität und den Wartungsgewohnheiten abhängt.

Kann Mesh-Schaumstoffgewebe effektiv gereinigt werden?

Ja, Mesh-Schaumstoffgewebe ist für eine einfache Pflege konzipiert. Das Material kann mit milder Seife und Wasser lokal gereinigt werden, und seine schnelltrocknenden Eigenschaften helfen, feuchtigkeitsbedingte Probleme zu vermeiden. Bei Produkten mit abnehmbarer Polsterung sorgt die Einhaltung der herstellerspezifischen Reinigungsanweisungen für optimale Ergebnisse.

Was macht Mesh-Schaumstoffgewebe gegenüber herkömmlichen Polstermaterialien überlegen?

Das Mesh-Schaumstoffgewebe kombiniert hervorragende Atmungsaktivität, exzellenten Aufprallschutz und verbesserte Haltbarkeit in einem einzigen Material. Durch seine einzigartige Struktur bietet es bessere Belüftung als massiver Schaumstoff, behält dabei aber seine schützenden Eigenschaften. Das Material zeichnet sich zudem durch eine bessere Feuchtigkeitsregulierung und Formstabilität im Vergleich zu herkömmlichen Polsteroptionen aus.